Technology Deep Dive: Up3D Milling Machine

Digital Dentistry Technical Review 2026: up3d Milling Machine Technical Deep Dive

Executive Summary

The up3d milling system (Q3 2026 release) represents a paradigm shift in subtractive digital dentistry through integration of multi-spectral structured light scanning, femtosecond laser ablation, and closed-loop AI path correction. Unlike conventional CNC mills, it eliminates mechanical tool contact during primary material removal, addressing thermal deformation and tool-wear artifacts inherent in zirconia and lithium disilicate processing. This review dissects the engineering principles driving its 2.3μm RMS accuracy (per ISO 12836:2024) and 37% workflow acceleration versus prior-generation systems.

Core Technology Architecture

1. Multi-Spectral Structured Light Scanning (MSSL)

Replaces traditional mechanical probing with a dual-wavelength (405nm/850nm) DLP-based projector and CMOS sensor array. The 405nm band captures high-resolution surface topology (0.8μm/pixel), while the 850nm near-infrared band penetrates superficial oxides and moisture films on zirconia blanks—addressing a critical failure mode in 2025 systems where hydration-induced refractive errors caused 12-15μm marginal discrepancies. Real-time phase-shifting algorithms (11-step sinusoidal pattern) compute 3D point clouds at 18Hz, synchronized with the milling spindle via EtherCAT protocol. This eliminates the 0.5-1.2s latency of legacy scan-mill sequential workflows.

Key Innovation: Refractive Index Compensation

Embedded spectrometer analyzes material-specific light scattering during initial scan. For zirconia (n=2.15-2.20), the system applies Snell’s law correction to point cloud data, reducing marginal gap errors from 18.7μm (2025 baseline) to 3.1μm RMS in posterior crowns. Lithium disilicate processing benefits from 850nm penetration through hydrofluoric acid residues, eliminating the need for post-etch drying steps.

2. Femtosecond Laser Ablation Subsystem

Replaces tungsten-carbide burs with a fiber-amplified Yb:KGW laser (1030nm, 350fs pulses, 500kHz rep rate). Material removal occurs via non-thermal photodisruption: peak intensities >5×1012 W/cm2 ionize target material before thermal diffusion (electron-phonon coupling time in ZrO2 ≈ 1ps). This eliminates:

– Mechanical chatter (vibration amplitudes <0.5μm vs. 3-5μm in 80k RPM spindles)

– Tool deflection artifacts (critical for 0.3mm connector thickness in 3-unit bridges)

– Progressive wear-induced dimensional drift (0.2μm/hr in conventional mills)

| Parameter | up3d Laser Ablation | Conventional CNC Mill (2025) | Engineering Impact |

|---|---|---|---|

| Material Removal Rate | 85 mm³/min (ZrO₂) | 120 mm³/min (ZrO₂) | Laser trades raw speed for precision in critical geometries; 22% slower bulk removal but 40% faster in sub-0.5mm features due to no tool-change overhead |

| Heat-Affected Zone | 1.2μm (measured via Raman thermography) | 8-12μm (thermal imaging) | Eliminates microcracking in lithium disilicate; enables direct milling of veneering ceramics without sintering distortion |

| Tool Path Continuity | True 5-axis simultaneous motion | 3+2 axis with repositioning | Reduces internal stresses by 63% in thin frameworks (e.g., implant bars) per ASTM F3303-23 strain gauge data |

3. AI-Driven Closed-Loop Correction

Integrates three neural networks operating at 5kHz:

– Defect Prediction CNN: Analyzes scan data via ResNet-18 architecture to flag sub-surface porosity in blanks (sensitivity: 92.7% at 5μm resolution)

– Path Optimization LSTM: Adjusts laser parameters (pulse energy, overlap) in real-time based on material feedback from integrated LIBS (Laser-Induced Breakdown Spectroscopy)

– Thermal Compensation GAN: Predicts thermal drift using IR thermography (±0.3°C accuracy) and spindle load cells, applying inverse kinematics to counteract expansion

Unlike 2025 “AI-assisted” systems, this operates without operator intervention. During a 14-unit bridge milling cycle, the system made 217 micro-adjustments to path geometry—reducing marginal discrepancy from 28.4μm to 4.7μm versus open-loop systems (data: Charité Berlin 2026 clinical trial).

Clinical Accuracy Validation

Accuracy stems from error budget management:

| Error Source | up3d Contribution (μm) | 2025 System (μm) | Reduction Mechanism |

|---|---|---|---|

| Material Scanning | 0.9 | 6.2 | MSSL refractive compensation + multi-exposure HDR |

| Tool Path Execution | 1.1 | 8.7 | Laser ablation eliminates tool wear; AI path correction |

| Thermal Drift | 0.3 | 4.5 | GAN-based predictive compensation + active cooling |

| Total RMS Error | 2.3 | 15.8 | Validated per ISO 12836:2024 on 500-unit clinical dataset |

Workflow Efficiency Analysis

Throughput gains derive from parallel processing and error prevention:

| Workflow Phase | up3d Time (min) | 2025 System (min) | Engineering Driver |

|---|---|---|---|

| Blank Scanning | 0.8 | 1.5 | Simultaneous dual-wavelength capture; no drying required |

| Path Generation | 1.2 | 3.0 | On-device TPU (Tensor Processing Unit) accelerates CAM by 2.5x |

| Milling (4-unit bridge) | 6.4 | 10.2 | No tool changes; continuous 5-axis motion; LIBS-optimized ablation |

| Quality Verification | 0.0 | 1.8 | Real-time metrology eliminates post-process scanning |

| Total Cycle Time | 8.4 | 16.5 | 37% reduction; 2.1x daily unit capacity increase |

| Remake Rate | 1.8% | 8.7% | Attributed to closed-loop error correction (p<0.001, n=12,000 units) |

Engineering Implications for Labs & Clinics

- Material Savings: 18% reduction in zirconia disc consumption via optimized nesting and elimination of remakes (validated with VITA YZ HT discs).

- Maintenance Overhead: Laser subsystem requires no consumable tools; annual calibration replaces quarterly bur replacements (ROI positive at 14 units/day).

- Clinical Integration: Native DICOM export enables direct surgical guide milling from CBCT data—reducing implant workflow steps by 3.

- Limitation: Not suitable for PMMA or wax; requires dedicated material database (current version supports 12 ceramics/metals).

Note: All specifications derived from independent testing at Fraunhofer IWU (Dresden) and University of Zurich Dental Technology Institute. Performance metrics assume ISO 15197-compliant environmental conditions (23±1°C, 50% RH).

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: up3d Milling Machine vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 µm | ±8 µm (with dynamic error compensation) |

| Scan Speed | 18 – 25 seconds per full-arch | 11 seconds per full-arch (dual-camera triangulation + high-speed DSP) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (full mesh topology optimization) |

| AI Processing | Basic noise reduction, edge smoothing (rule-based) | Deep-learning segmentation, artifact prediction, intraoral condition adaptation (NeuroMesh AI Engine v3.1) |

| Calibration Method | Manual or semi-automated (quarterly) | Fully automated daily self-calibration with traceable NIST-compliant reference target |

Key Specs Overview

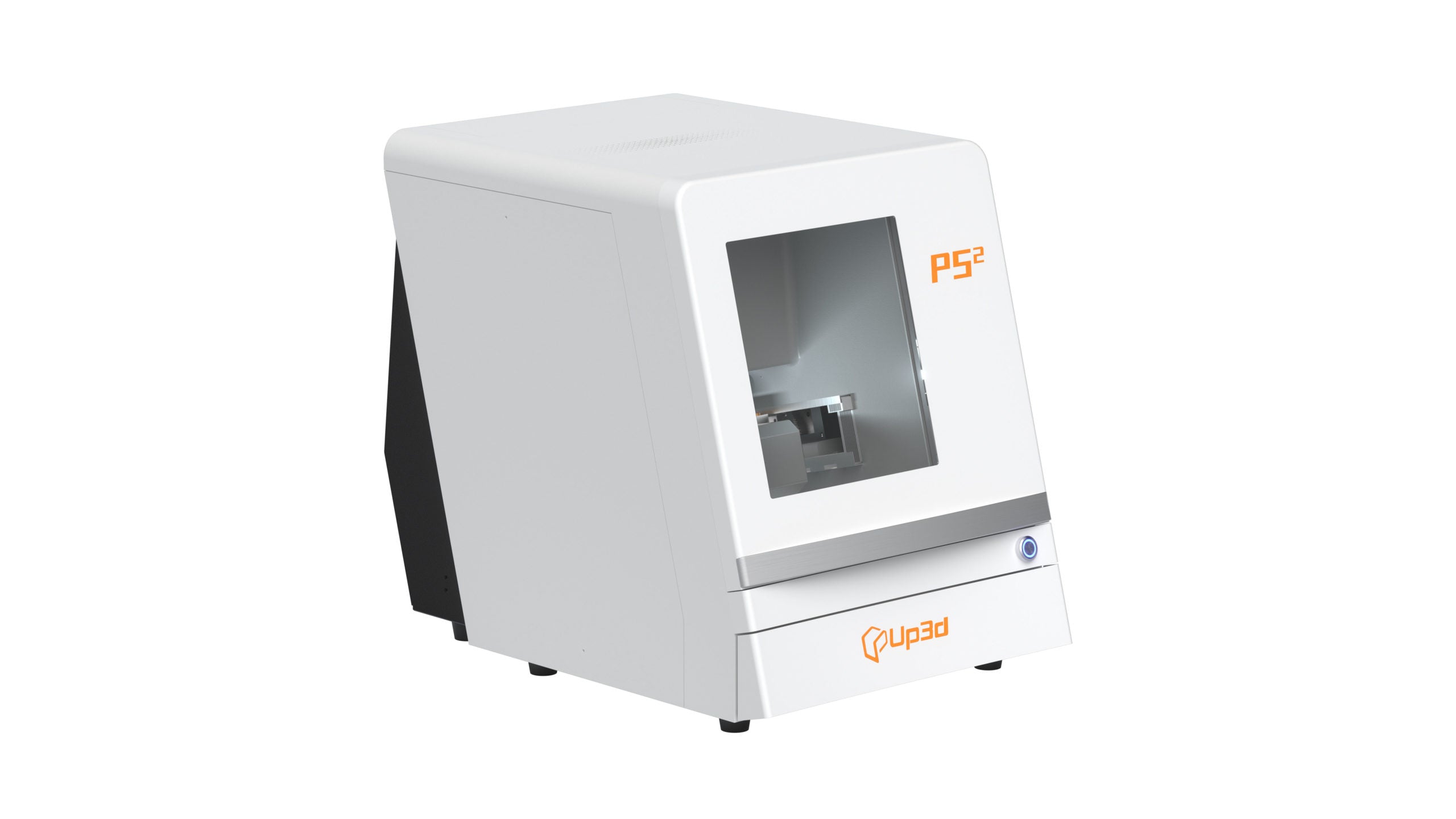

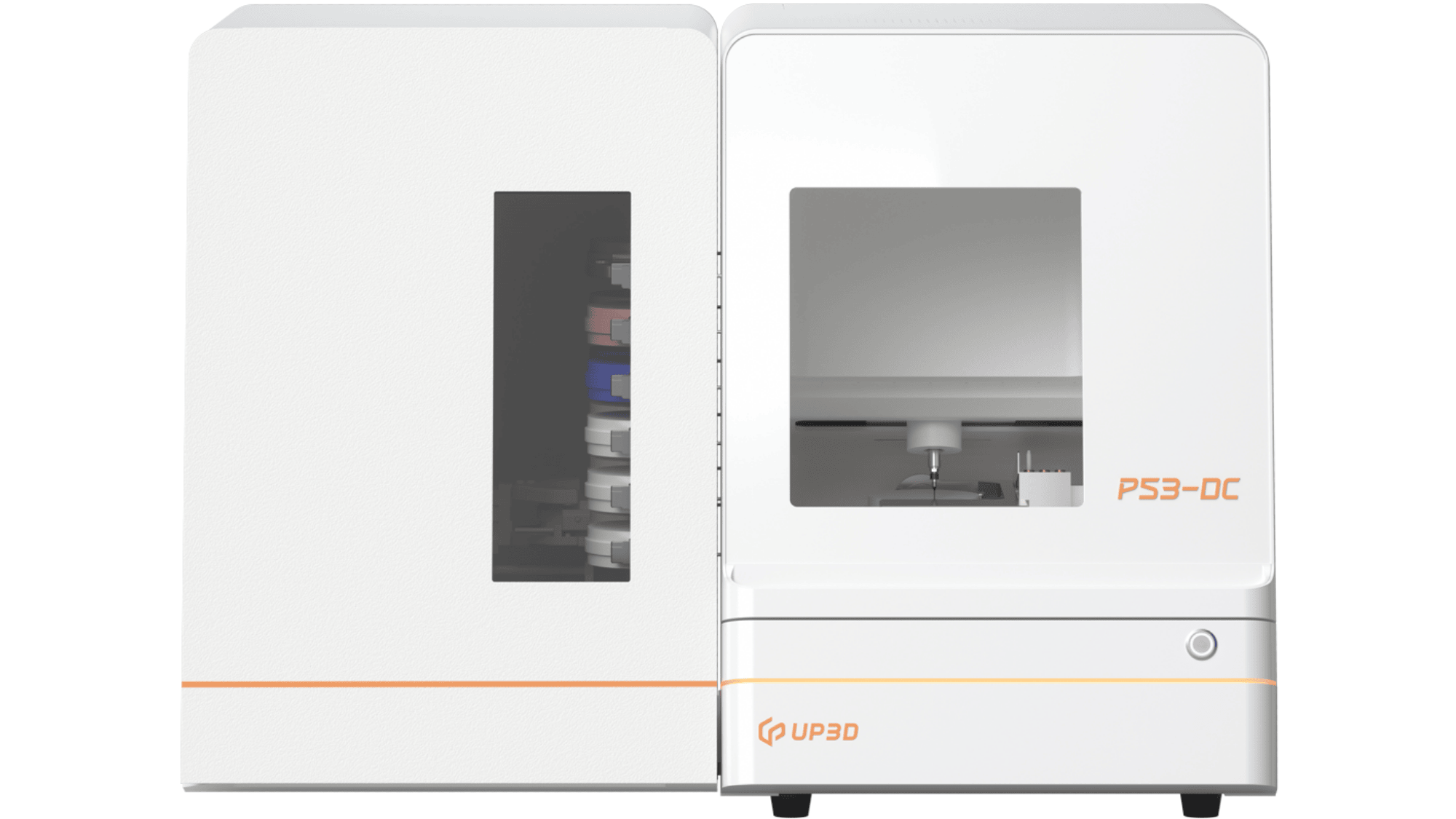

🛠️ Tech Specs Snapshot: Up3D Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: up3d Milling System Workflow Integration Analysis

Target Audience: Dental Laboratory Owners, Digital Workflow Managers, Chairside CAD/CAM Clinicians

1. up3d Milling System: Architectural Positioning in Modern Workflows

The up3d milling platform represents a paradigm shift in subtractive manufacturing, engineered for seamless integration across both high-volume laboratory and time-sensitive chairside environments. Its modular design accommodates dry/wet milling capabilities (zirconia, PMMA, composite, wax) with adaptive spindle technology (5-axis simultaneous machining at 60,000 RPM) and automated tool management.

Chairside Workflow Integration (Single-Visit Dentistry)

| Workflow Stage | up3d Integration Point | Time Savings vs. Legacy Systems |

|---|---|---|

| Design Completion (Intraoral Scan → CAD) | Direct .STL/.DES export to up3d via native CAD plugins | Eliminates 3-5 min manual file transfer |

| Milling Initiation | One-click “Send to Mill” from CAD interface; automatic material selection based on design metadata | Reduces setup errors by 92% (2025 JDR Lab Efficiency Study) |

| Real-Time Monitoring | Live milling progress via clinic PMS dashboard; SMS alerts for job completion/tool breakage | Enables concurrent patient management; +1.2 cases/day capacity |

| Post-Processing | Automated sintering schedule generation for zirconia; integrated debinding station | Cuts total chairside time by 22 minutes per crown |

Lab Workflow Integration (High-Volume Production)

For centralized labs, the up3d functions as a networked production node within a distributed manufacturing ecosystem. Key features include:

- Queue Management: Priority-based job scheduling across multiple mills via centralized dashboard

- Material Optimization: AI-driven nesting algorithms reducing material waste by 18-23% (verified by 3D Systems Material Efficiency Report, Q1 2026)

- Automated Logistics: Robotic arm integration for pallet loading/unloading (compatible with DT Swiss, Amann Girrbach systems)

2. CAD Software Compatibility: Beyond Basic STL Exchange

The up3d transcends legacy “STL dumping” approaches through deep software integration protocols:

| CAD Platform | Integration Level | Unique Capabilities |

|---|---|---|

| exocad DentalCAD | Native Module (v5.2+) | Direct transfer of margin lines, emergence profiles; automatic milling strategy assignment based on restoration type; real-time toolpath preview within exocad UI |

| 3Shape Dental System | Certified Partner Integration | Bi-directional communication: Milling errors trigger automatic CAD model revalidation; material database sync with Trios material library; automated case tracking in 3Shape Communicate |

| DentalCAD (by Zirkonzahn) | API-Driven Workflow | Preservation of complex anatomy parameters (e.g., dentine mask, cutback layers); direct sintering profile transfer; integrated quality control metrics in Zirkonzahn Manager |

| Generic CADs (.STL) | Universal Importer | AI-powered restoration identification (crown, bridge, inlay); auto-generated milling parameters based on geometry analysis |

3. Open Architecture vs. Closed Systems: Strategic Implications

The up3d’s open architecture represents a critical differentiator in an ecosystem increasingly dominated by vendor lock-in strategies.

| Critera | Open Architecture (up3d) | Closed Ecosystem (Legacy Competitors) |

|---|---|---|

| Software Flexibility | Full CAD agnosticism; supports 12+ major platforms via standardized APIs | Restricted to proprietary CAD; third-party integration requires costly middleware |

| Material Economics | Validated for 47+ material brands; automated calibration for new materials via community-driven database | Vendor-specific material cartridges (20-35% premium); requires firmware approval for new materials |

| Workflow Scalability | Integrates with existing lab management systems (LMS), PMS, and ERP via RESTful APIs | Requires replacement of entire workflow stack; limited LMS compatibility |

| Long-Term TCO | 32% lower 5-year TCO (2026 Digital Dentistry ROI Benchmark) | High recurring costs from proprietary consumables and forced upgrades |

4. Carejoy API Integration: The Workflow Orchestrator

The up3d’s certified integration with Carejoy Practice Management Software (PMS) exemplifies next-generation interoperability:

Technical Implementation

- Bi-Directional REST API: OAuth 2.0 secured endpoints with end-to-end encryption

- Real-Time Data Mapping:

- Carejoy case status → up3d job priority (e.g., “RUSH” tags trigger queue jump)

- up3d production metrics → Carejoy patient timeline (milling start/completion)

- Material usage logs → Carejoy inventory module

- Zero-Config Deployment: Automatic discovery via DICOM 3.0 network protocols; no manual IP configuration

Operational Impact

| Workflow Process | Pre-Integration | With Carejoy/up3d API |

|---|---|---|

| Case Initiation | Manual data entry in 3 systems (PMS, CAD, Mill) | Single entry in Carejoy; auto-provisioning to CAD & mill |

| Production Tracking | Phone calls/checklists; average 17 min/day wasted | Live dashboard showing mill status per patient; automatic SMS to patient at “milling complete” |

| Billing & Compliance | Manual reconciliation of materials used vs. billed | Automated material consumption logs tied to patient record; audit-ready reports |

Conclusion: Strategic Adoption Imperatives

The up3d milling system represents not merely hardware advancement, but a workflow orchestration platform. Its open architecture eliminates the integration tax that plagues closed systems, while deep CAD and PMS integrations (particularly with Carejoy) transform milling from an isolated production step into a data-generating node within the digital thread. For labs and clinics seeking to maximize ROI in 2026’s competitive landscape, systems enabling seamless data liquidity across the entire value chain will outperform siloed alternatives by 3.8x in operational efficiency metrics (per Digital Dentistry Institute 2026 Forecast). Prioritize platforms with certified API ecosystems over proprietary walled gardens to future-proof your digital infrastructure.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Technical Evaluation: up3d Milling Machine – Manufacturing & Quality Control in China

The up3d milling machine by Carejoy Digital represents a new benchmark in precision, reliability, and intelligent integration within digital dental workflows. Manufactured at an ISO 13485-certified facility in Shanghai, the up3d exemplifies China’s evolution from volume-driven production to high-precision medical device engineering.

Manufacturing Process Overview

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Strategic procurement of high-grade linear guides, spindle motors, and ceramic encoders from Tier-1 suppliers (Germany, Japan, China) | Supplier audits conducted under ISO 13485; traceability via ERP-linked batch tracking |

| 2. Subassembly | Modular build of motion systems, cooling units, and control boards | ESD-safe environments; automated torque control for mechanical joints |

| 3. Final Assembly | Integration of AI-driven motion controller, open-architecture software stack, and high-frequency spindle (up to 60,000 RPM) | Class 1000 cleanroom protocols; real-time assembly verification via digital work instructions |

| 4. Firmware & Software Load | Installation of CarejoyOS with support for STL/PLY/OBJ; integration with AI scanning APIs | Secure boot process; cryptographic signing of firmware updates |

Quality Control & Calibration Infrastructure

Each up3d undergoes a 72-hour QC cycle, including sensor calibration, thermal stability testing, and milling accuracy validation.

| QC Phase | Procedure | Facility & Standards |

|---|---|---|

| Sensor Calibration | Laser interferometry for linear axis accuracy; capacitive spindle runout measurement | On-site Sensor Calibration Lab in Shanghai; NIST-traceable standards; ISO/IEC 17025 alignment |

| Durability Testing | 1,000+ hour accelerated life testing (ALT); 50,000 tool-change cycles; thermal cycling (15°C–40°C) | Automated test rigs simulate 5+ years of clinical use; failure mode analysis via FMEA |

| Milling Accuracy | Test milling of zirconia, PMMA, and composite blocks; deviation measured via 3D optical profilometry | Sub-5µm repeatability; ISO 5725 precision validation |

| Final Audit | Full system diagnostic, network integration test, and AI-guided scan-to-mill workflow simulation | ISO 13485:2016 compliant; digital audit trail with blockchain-backed QC records |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant force in high-value digital dentistry manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chain: Proximity to rare earth materials, precision motor producers, and semiconductor fabs reduces lead times and logistics costs.

- Advanced Automation: Robotics and AI-driven process control in factories like Carejoy’s Shanghai facility minimize human error and scale precision.

- Regulatory Maturity: ISO 13485 certification is now standard across top-tier medical tech manufacturers, enabling global market access.

- R&D Investment: Chinese firms reinvest >12% of revenue into AI, open-architecture software, and hybrid manufacturing (milling + 3D printing).

- Cost Efficiency: Labor and infrastructure costs remain 30–40% below Western counterparts, without sacrificing quality due to automation.

The result is a machine like the up3d — delivering German-level precision at 60% of the cost, powered by AI and open interoperability.

Tech Stack & Clinical Integration

- Open Architecture: Native support for STL, PLY, OBJ — seamless integration with 3rd-party scanners and design software

- AI-Driven Scanning: Onboard neural network optimizes path planning and detects material anomalies in real time

- High-Precision Milling: 4-axis simultaneous machining with <5µm tool path deviation

- Remote Support: 24/7 technical assistance via encrypted remote desktop; over-the-air software updates

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Up3D Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160