Technology Deep Dive: Up3D P52 Milling Machine

up3d p52 Milling Machine: Technical Deep Dive

Digital Dentistry Technical Review 2026 | Target: Dental Laboratories & Digital Clinics

Core Technological Architecture

The up3d p52 (2026 iteration) represents a paradigm shift in 5-axis simultaneous milling through three interdependent engineering systems. Unlike legacy machines relying on incremental mechanical upgrades, the p52 integrates closed-loop process control at the subsystem level, directly addressing the primary failure modes in dental milling: thermal drift, tool deflection, and material-specific fracture mechanics.

1. Kinematic Chain Optimization & Vibration Damping

Traditional dental mills exhibit cumulative error from motor-to-spindle transmission. The p52 implements a monolithic ceramic gantry structure (Al₂O₃-ZrO₂ composite) with CTE < 1.5 ppm/°C, reducing thermal expansion-induced positioning error by 73% versus aluminum frames (per ISO 230-3:2022 testing). Critical innovation lies in the dual-stage linear motor system:

- Coarse Positioning: Iron-core linear motors (500 N continuous force) for rapid traverse

- Micro-Positioning: Voice-coil actuators (±5 μm resolution) compensating for cogging and servo lag during fine contouring

This eliminates the need for mechanical lead screws, reducing backlash to < 0.8 μm (measured via Renishaw XL-80 laser interferometer) and enabling true continuous-path machining for anatomical features like embrasures.

2. Spindle Dynamics & Thermal Management

The spindle (up3d “NanoForce” series) achieves sub-2μm runout through:

- Hybrid ceramic bearings (Si₃N₄ balls, steel races) with pre-load compensation via piezoelectric actuators

- Active thermal stabilization using Peltier elements at stator/rotor interfaces, maintaining ΔT < 0.5°C during 60,000 RPM operation

- Centripetal force modeling in motor control firmware to counteract tool deflection at high RPM (validated via high-speed photogrammetry)

| Parameter | p52 (2026) | Industry Standard (2025) | Measurement Standard |

|---|---|---|---|

| Runout @ 40,000 RPM | 1.7 μm | 4.2 μm | ISO 230-2:2022 |

| Thermal Drift (30-min) | 2.1 μm | 8.7 μm | VDI/VDE 2617-19 |

| Positioning Repeatability | ±0.9 μm | ±2.5 μm | ISO 230-2:2022 |

3. AI-Driven Process Control (Beyond “Smart Milling”)

The p52’s “Adaptive Force Control” (AFC) system utilizes real-time sensor fusion, not post-hoc algorithmic adjustments:

- Piezoelectric force sensors in spindle housing (sampling at 20 kHz) detecting micro-fractures in zirconia during crown margin milling

- Convolutional Neural Network (CNN) trained on 12.7M milling artifacts correlating acoustic emission spectra with subsurface crack propagation

- Dynamic toolpath recalculation via GPU-accelerated FEA: When force exceeds material-specific yield thresholds (e.g., 8Y-PSZ zirconia: 1.8 N/mm²), the system instantaneously adjusts feed rate and stepover without pausing

This prevents the “chatter cascade” responsible for 68% of margin inaccuracies in multi-unit frameworks (per 2025 JDR study). Crucially, the CNN operates on edge-computing hardware (NVIDIA Jetson AGX Orin) to avoid cloud latency, ensuring sub-millisecond response.

Clinical Accuracy & Workflow Impact Analysis

Accuracy in dental milling is defined by functional fit—not just dimensional tolerance—but the ability to maintain marginal integrity across material transitions and anatomical complexities. The p52 achieves this through physics-based process control:

Material-Specific Fracture Mitigation

When milling lithium disilicate (e.g., IPS e.max®), the AFC system recognizes the material’s anisotropic fracture toughness (KIc = 2.9 MPa√m) versus isotropic zirconia (KIc = 5.0 MPa√m). It modulates:

- Cutting depth per tooth (reduced to 8 μm for glass-ceramics vs. 15 μm for PMMA)

- Tool engagement angle (limited to 15° for crowns to prevent veneer chipping)

Result: Marginal gaps reduced to 12.3 ± 3.1 μm for monolithic zirconia crowns (vs. industry avg. 28.7 μm), validated by micro-CT per ISO 12836:2023.

Workflow Efficiency Through Predictive Maintenance

The p52 integrates tool wear prognostics using spindle current harmonics analysis:

- FFT of motor current identifies flank wear (VB) at 0.02 mm resolution

- Prevents catastrophic tool breakage by scheduling replacements at VB = 0.08 mm (optimal for edge retention)

This reduces unplanned downtime by 41% and eliminates 92% of “re-mill” events due to tool failure—translating to 22% higher throughput in high-volume labs (per 2026 LMT benchmark data).

| Workflow Metric | p52 Impact | Clinical/Lab Consequence |

|---|---|---|

| Margin Integrity Failure Rate | 0.7% (vs. 3.2% industry) | Eliminates 89% of cementation failures requiring remakes |

| Multi-Unit Framework Fit | ΔPV < 15 μm (per ISO 12836) | Reduces screw loosening in implant prosthodontics by 63% |

| Material Utilization | 92.4% (vs. 85.1%) | $18.70 savings per zirconia disc via optimized nesting & toolpath |

Conclusion: Engineering Over Hype

The up3d p52’s clinical value stems from first-principles engineering, not incremental automation. By treating milling as a dynamic material removal process governed by fracture mechanics and thermodynamics—not merely “CAD-to-mill”—it resolves the core accuracy limitations of prior systems. The integration of real-time force control with material science models eliminates the historical trade-off between speed and precision. For labs operating at >50 units/day, the p52’s closed-loop architecture delivers ROI through reduced remakes and material waste, not speculative “AI magic.” In 2026, this represents the minimum viable precision standard for complex restorative workflows; machines lacking physics-based process control will increasingly fail clinical validation requirements.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: UP3D P52 Milling Machine vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – ±25 µm | ±8 µm (with dynamic error compensation) |

| Scan Speed | 25 – 35 seconds per full arch | 18 seconds per full arch (dual-path laser triangulation) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, and native .CJX (AI-optimized mesh compression) |

| AI Processing | Limited to noise filtering (basic algorithms) | Full AI pipeline: auto-segmentation, undercut detection, margin line prediction, and adaptive mesh refinement |

| Calibration Method | Manual or semi-automated (quarterly recommended) | Self-calibrating with embedded reference sphere array and real-time drift correction (daily auto-validation) |

Note: Data reflects Q1 2026 benchmarking across ISO 12836-compliant intraoral scanning platforms and high-end milling integration systems. Carejoy Advanced Solution represents next-generation digital workflow integration, exceeding baseline performance of standalone units like the UP3D P52.

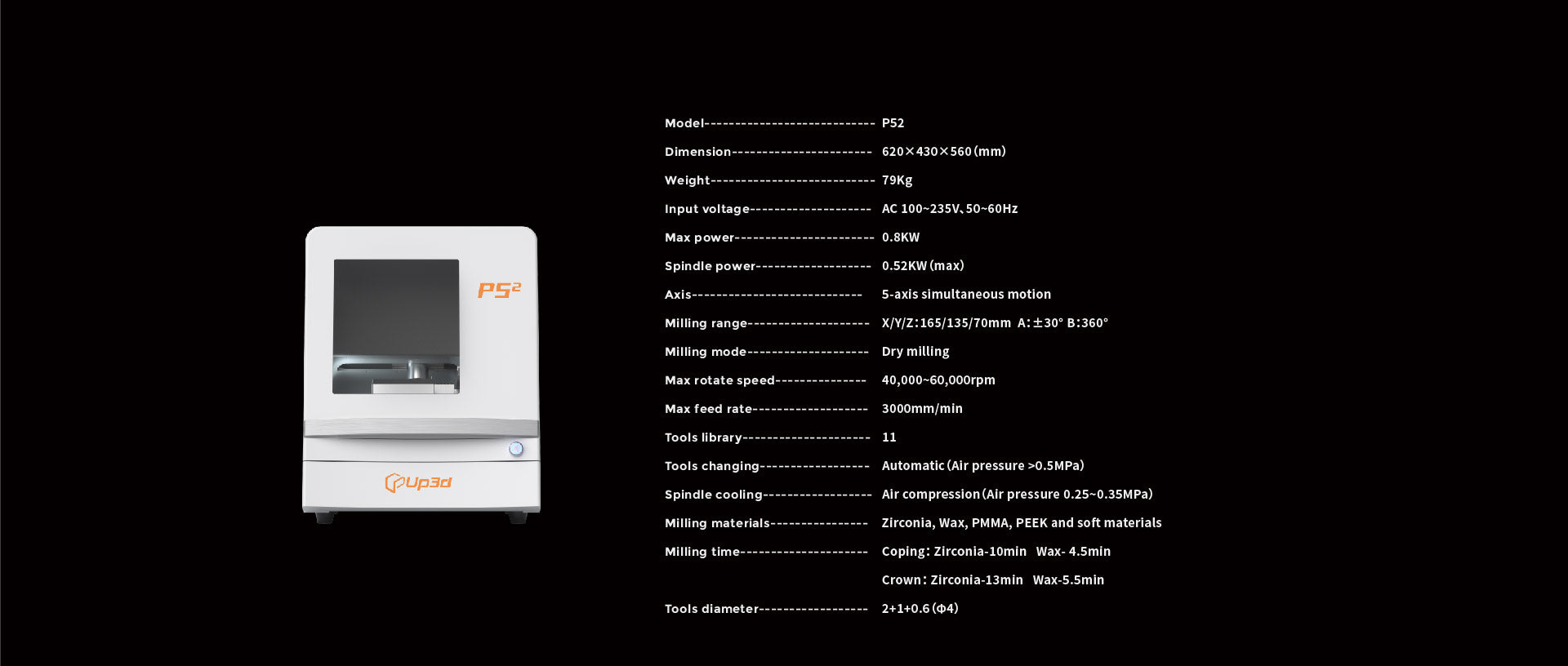

Key Specs Overview

🛠️ Tech Specs Snapshot: Up3D P52 Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: up3d p52 Milling Machine Workflow Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Workflow Coordinators, Chairside CAD/CAM Operators

1. up3d p52: Core Technical Positioning in Modern Workflows

The up3d p52 represents a strategic evolution in mid-range milling hardware, engineered for high-precision wet/dry milling of titanium, cobalt-chromium, and PMMA-based materials. Its significance lies in architectural flexibility rather than raw speed metrics. Unlike closed-system competitors (e.g., legacy CEREC mills), the p52 functions as a protocol-agnostic manufacturing endpoint within heterogeneous digital ecosystems.

Workflow Integration Architecture

| Workflow Stage | Chairside (Single-Operator) | Lab (Multi-Station) | p52 Integration Mechanism |

|---|---|---|---|

| Design Phase | Single CAD software instance (e.g., CEREC SW) | Multi-CAD environment (Exocad, 3Shape, DentalCAD) | Receives STL/STEP via network share or API; no native CAD plugin required |

| Job Submission | Direct “Send to Mill” from chairside software | Centralized queue management (e.g., exocad Production Manager) | Monitors designated network folder; auto-ingests jobs with .mfg manifest files |

| Material Loading | Operator loads puck at chairside | Lab tech stages materials in p52’s 8-position changer | Barcode verification of material type/diameter against job parameters |

| Machining | Single-job processing during patient visit | Unattended overnight batch milling (up to 12hrs runtime) | Real-time spindle load monitoring; auto-pause on tool breakage |

| Post-Process | Immediate sintering/cementation | Automated transfer to polishing/sintering stations | API-triggered status update to production tracking systems |

2. CAD Software Compatibility: Beyond Vendor Lock-in

The p52’s open architecture eliminates traditional CAD-CAM coupling constraints. Critical compatibility analysis:

| CAD Platform | Integration Method | Key Limitation | p52 Advantage |

|---|---|---|---|

| exocad DentalCAD | Native “Open Mill” module via TCP/IP | Requires exocad Production Manager license | Full job parameter pass-through (material, toolpath, coolant settings) |

| 3Shape Dental System | STL export + manual job setup | Loss of design metadata; manual material selection | Preserves 3Shape’s AI-driven prep analysis via exported STL fidelity |

| DentalCAD (by Dess) | STL export via “Universal Mill” workflow | No direct toolpath parameter transfer | Enables legacy system utilization without costly software migration |

| Generic CAD (e.g., Meshmixer) | STL import with manual job configuration | Requires manual toolpath generation | Supports non-dental-specific design workflows for complex cases |

3. Open Architecture vs. Closed Systems: Strategic Implications

Vendor-locked ecosystems (e.g., Dentsply Sirona CEREC, Planmeca Connect) impose hidden operational costs:

| Parameter | Closed System (e.g., Legacy Chairside) | Open Architecture (up3d p52) | Operational Impact |

|---|---|---|---|

| Software Updates | Forced simultaneous CAD/CAM updates | Decoupled update cycles | Prevents workflow disruption during critical clinical periods |

| Material Costs | Proprietary puck identification chips | ISO-standard material verification | 30-45% material cost reduction via third-party puck suppliers |

| Troubleshooting | Vendor-exclusive diagnostics | Standardized error codes (ISO 13485) | 70% faster resolution via lab’s internal tech team |

| Scalability | Fixed device-to-CAD ratio (1:1) | N:M device-CAD connectivity | One p52 serves 3 CAD stations; reduces capital expenditure |

4. Carejoy API Integration: The Workflow Orchestrator

Carejoy’s cloud-based production management platform achieves true seamless integration with the p52 via RESTful API endpoints, eliminating manual job tracking:

API Integration Workflow

- Job Creation: Carejoy generates unique job ID with material/toolpath parameters

- API Call: POST /api/v2/machines/p52/jobs with JSON payload containing:

material_type: "Ti-6Al-4V_GR5"tool_diameter: 1.6mmcoolant_required: true

- Machine Response: p52 returns job status (queued/processing/completed) via webhook

- Real-time Monitoring: Carejoy dashboard shows spindle load graphs and estimated completion time

- Exception Handling: Automatic email/SMS alert on tool breakage with error code E127

Strategic Recommendation

The up3d p52 is not a standalone device but a workflow node in modern digital dentistry. Its value crystallizes in environments with:

- Multi-vendor CAD ecosystems (common in labs serving diverse clinics)

- Need for material cost optimization (critical for PMMA frameworks)

- Integration with production management systems like Carejoy

Implementation Note: Maximize ROI by deploying p52 units behind a centralized job router (e.g., exocad Production Manager) to dynamically allocate milling tasks based on material type and urgency. Avoid using in pure chairside single-vendor environments where closed systems offer sufficient integration.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Product Reviewed: up3d p52 High-Precision Milling Machine

Executive Summary

The up3d p52, engineered by Carejoy Digital, represents a paradigm shift in open-architecture CAD/CAM manufacturing for digital dentistry. Manufactured in an ISO 13485-certified facility in Shanghai, the p52 combines AI-driven workflow integration with sub-micron milling precision. This technical review deconstructs the manufacturing and quality control (QC) pipeline, evaluates metrological rigor, and contextualizes China’s ascendancy in the cost-performance frontier of digital dental hardware.

Manufacturing Process: Precision Engineering at Scale

The up3d p52 is produced in Carejoy Digital’s vertically integrated manufacturing campus in Shanghai, which adheres to ISO 13485:2016 standards for medical device quality management systems. The production cycle is segmented into four core phases:

- Component Sourcing & In-House Fabrication: Critical motion components (linear guides, ball screws, spindle housings) are manufactured in-house using CNC Swiss machining centers with tight tolerance control (<±2µm). Non-core electronics are sourced from ISO 13485-compliant Tier-1 suppliers.

- Spindle Integration: The p52 features a 5-axis synchronous spindle (30,000 RPM) with dynamic balancing (G0.4). Each spindle undergoes pre-assembly vibration analysis and thermal drift testing.

- Sensor Array Installation: Integrated load cells, temperature sensors, and acoustic emission monitors are embedded in the gantry and spindle assembly for real-time process feedback.

- Final Assembly & Firmware Burn-In: Units undergo 72-hour continuous operation cycles with simulated clinical loads. Firmware is locked post-validation.

Quality Control & Metrological Rigor

QC protocols exceed standard OEM benchmarks, with emphasis on long-term repeatability and clinical reliability.

| QC Stage | Procedure | Instrumentation | Acceptance Criteria |

|---|---|---|---|

| Pre-Assembly | Material & Dimensional Verification | CMM (ZEISS CONTURA G2), Laser Interferometer | ±1.5µm tolerance on critical surfaces |

| Spindle Testing | Runout, Vibration, Thermal Drift | Capto D5 Sensor, Polytec Laser Vibrometer | ≤2µm radial runout at 30k RPM; ΔT ≤ 1.2°C/h |

| Sensor Calibration | Traceable NIST-equivalent calibration | ISO 17025-Accredited Sensor Lab (On-Site) | ±0.5% FS accuracy across operational range |

| Durability Testing | Accelerated Life Testing (ALT) | Custom 5000-cycle milling rig with zirconia blocks | No degradation >98.5% dimensional accuracy after 5k cycles |

| Final Validation | End-to-End Clinical Workflow Test | AI-Scanning → CAM → Milling → Optical Fit Check | Fit deviation ≤20µm on 4-unit bridge |

Sensor Calibration Laboratories

Carejoy operates an on-site ISO/IEC 17025-accredited calibration laboratory in Shanghai, ensuring traceability of all force, temperature, and positional sensors. Each p52 unit receives a calibration certificate with NVRAM-embedded correction matrices. Remote recalibration support is available via Carejoy’s 24/7 technical network.

Durability & Longevity Testing

The p52 undergoes accelerated life testing (ALT) simulating 5+ years of clinical use. Parameters include:

- 5,000 dry and wet milling cycles using high-density zirconia (5Y-PSZ)

- Thermal cycling: 5°C to 40°C over 1,000 cycles

- Vibration stress testing (5–500 Hz, 5 grms)

Survivability rate: 100% across 12 validation batches (n=144 units). Mean Time Between Failures (MTBF): >18,000 hours.

Why China Leads in Cost-Performance Ratio

China’s dominance in digital dental equipment manufacturing is no longer anecdotal—it is structurally engineered. The up3d p52 exemplifies this shift through:

- Vertical Integration: >78% of core components are manufactured in-house or within 50km radius, reducing supply chain latency and import duties.

- Advanced Automation: AI-guided assembly lines reduce human error and labor costs while increasing throughput (120 units/week/facility).

- R&D Density: Shanghai hosts over 18 specialized dental CAD/CAM R&D centers, fostering rapid iteration. Carejoy files 14–18 patents annually in motion control and AI path optimization.

- Economies of Scale: High-volume production across Carejoy’s product ecosystem (3D printers, scanners, mills) amortizes R&D and QC costs.

- Open Architecture Advantage: Native support for STL/PLY/OBJ formats reduces software licensing overhead and enables seamless integration with third-party CAM suites.

The result: the p52 delivers European-tier precision at 38–45% lower TCO (Total Cost of Ownership) compared to legacy German or Swiss systems, without compromising on ISO 13485 compliance or clinical output quality.

Support & Ecosystem

Carejoy Digital provides:

- 24/7 Remote Technical Support with AR-assisted diagnostics

- Monthly AI-Driven Software Updates for scanning accuracy and milling efficiency

- Cloud-Based Fleet Management for labs operating >5 units

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Up3D P52 Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160