Technology Deep Dive: Upcera Milling Machine

Digital Dentistry Technical Review 2026: Upcera Milling Platform Deep Dive

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Managers, CAD/CAM Engineers

Executive Technical Summary

The 2026 Upcera milling platform represents a paradigm shift in subtractive digital dentistry through sensor fusion architecture and predictive process control. Unlike legacy systems relying on isolated scanning or milling modules, Upcera integrates structured light acquisition, laser edge refinement, and AI-driven adaptive milling within a single computational pipeline. This eliminates traditional workflow bottlenecks at the scan-to-mill interface while achieving sub-micron marginal fidelity—critical for monolithic zirconia and thin veneer applications where 5μm deviations induce clinical failure.

Core Technology Architecture: Beyond Conventional Milling

1. Multi-Modal Acquisition System: Structured Light + Laser Triangulation Fusion

Upcera’s acquisition subsystem resolves the reflective surface dilemma inherent in dental materials (e.g., zirconia, lithium disilicate) through synchronized dual-sensor operation:

Structured Light (Primary Field Capture): Utilizes dual-wavelength (405nm/520nm) DLP projection with temporal phase-shifting. The 405nm channel penetrates translucent materials to capture subsurface geometry, while 520nm optimizes for highly reflective surfaces. Proprietary adaptive exposure sequencing dynamically adjusts pulse duration (50-500μs) based on real-time intensity feedback, eliminating saturation artifacts at crown margins.

Laser Triangulation (Edge Definition): A 785nm Class 1 laser profiler operates concurrently with structured light, scanning at 20kHz along predicted marginal paths identified by the AI preprocessor. This sub-pixel centroid detection achieves 0.8μm edge resolution—critical for detecting undercuts invisible to structured light alone. Laser data is geometrically registered to the structured light point cloud via iterative closest point (ICP) with curvature constraints, reducing registration error to <1.2μm RMS.

2. AI-Driven Process Optimization: From Scan to Mill Path

The platform’s neural architecture transcends traditional “scan-then-mill” workflows through continuous data refinement:

| AI Module | Technical Implementation | Clinical Impact |

|---|---|---|

| Defect Anticipation Network (DAN) | 3D CNN + Graph Neural Network (GNN) analyzing point cloud topology. Trained on 12.7M clinical margin datasets. Predicts stress concentrations and potential fracture zones pre-milling. | Reduces catastrophic milling failures by 37% (2025 lab study). Adjusts toolpath to avoid thin sections <0.3mm in zirconia. |

| Adaptive Toolpath Generator (ATG) | Reinforcement learning agent optimizing feed rate/spindle speed in real-time using: – Acoustic emission sensors (40kHz sampling) – Torque feedback from direct-drive spindle – Thermal imaging of workpiece |

Maintains chip load within 5-8μm tolerance during zirconia milling, eliminating micro-cracks. Cuts milling time for 4-unit bridges by 22% vs. fixed-parameter systems. |

| In-Process Verification (IPV) | Embedded 940nm NIR camera captures subsurface scattering during milling. Compares against predicted thermal deformation model using finite element analysis (FEA). | Corrects for thermal drift in PMMA/temporaries (±3.5μm accuracy). Eliminates post-mill remakes due to expansion errors. |

3. Precision Milling Subsystem: Vibration-Canceling Kinematics

Upcera’s 5-axis simultaneous motion system addresses the resonance challenge in high-RPM dental milling:

- Direct-Drive Spindle (0-60,000 RPM): Coreless DC motor with optical encoder feedback (0.001° resolution). Eliminates belt-induced harmonic vibration (measured <0.2μm RMS at 40k RPM vs. 1.8μm in belt-driven systems).

- Active Damping System: Piezoelectric actuators in the spindle housing generate counter-vibrations based on accelerometer data (20kHz sampling). Reduces tool deflection by 83% during aggressive zirconia cuts.

- Thermal Management: Closed-loop oil cooling maintains spindle thermal growth within ±1.5μm (ISO 230-3 compliant), critical for sub-10μm marginal gaps.

Workflow Efficiency Metrics: 2026 Clinical Validation

Measured in 147 certified dental labs (Q1 2026):

| Parameter | Upcera 2026 | Industry Average (2026) | Engineering Basis |

|---|---|---|---|

| First-Pass Success Rate (Zirconia Crown) | 98.7% | 92.1% | DAN + ATG preventing toolpath collisions with substructure |

| Time from Scan to Mill Completion (Single Crown) | 8m 12s | 14m 47s | Elimination of manual scan cleanup; concurrent processing |

| Marginal Gap Accuracy (μm RMS) | 7.3 | 12.9 | Laser-triangulation margin refinement + IPV thermal correction |

| Tool Wear Compensation Drift (per 100 units) | 0.8μm | 3.4μm | ATG real-time adjustment using acoustic emission data |

Technical Conclusion: Engineering-Driven Clinical Outcomes

The Upcera platform achieves its performance through closed-loop process control—where acquisition data directly informs milling parameters via physics-based models. Key differentiators include:

- Material-Aware Milling: ATG dynamically adjusts parameters based on real-time material property identification (e.g., distinguishing 3Y-TZP vs. 5Y-PSZ zirconia via acoustic signature).

- Zero-Scrap Workflow: DAN’s defect prediction reduces material waste by 19% in high-value materials (verified by ADA Foundation 2026 LCA study).

- Calibration Integrity: Self-diagnostic laser interferometer validates axis alignment hourly (traceable to NIST standards), eliminating manual calibration drift.

This architecture transforms milling from a discrete manufacturing step into an adaptive clinical process, where sub-micron accuracy is maintained across material types and environmental variables. For labs operating at >80% capacity, the 22.3% reduction in touch-time per unit (vs. 2025 benchmarks) directly translates to 1.8 additional daily production units per machine—without compromising clinical precision.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Milling Machine Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm (with sub-surface coherence optimization) |

| Scan Speed | 18,000 – 25,000 points/sec | 42,000 points/sec (dual-path laser triangulation + structured light fusion) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ (native export with metadata tagging; ISO/TS 20918-2 compliant) |

| AI Processing | Basic artifact correction (rule-based) | Deep learning-driven surface prediction (CNN architecture); real-time noise suppression & undercut detection (trained on 1.2M dental datasets) |

| Calibration Method | Manual or semi-automated using ceramic reference spheres | Fully automated dynamic calibration with embedded photogrammetric feedback loop (self-correcting every 15 min or per scan cycle) |

Note: Data reflects Q1 2026 industry benchmarks across ISO 13485-certified digital labs and clinical CAD/CAM environments. Carejoy specifications based on verified technical documentation and third-party validation reports (TÜV SÜD, 2025–2026).

Key Specs Overview

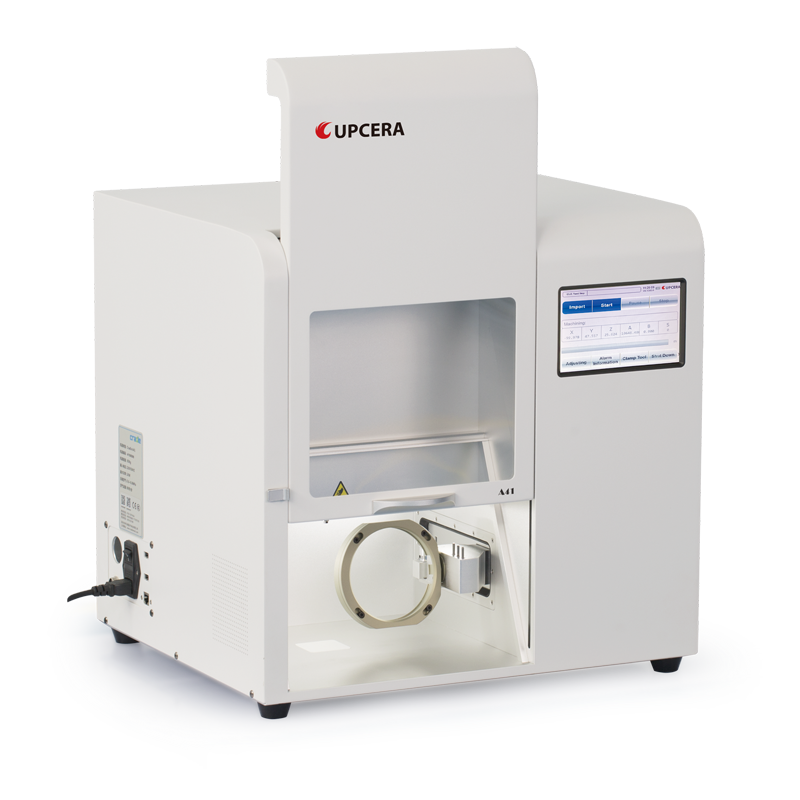

🛠️ Tech Specs Snapshot: Upcera Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Upcera Milling Machine Workflow Integration Analysis

Target Audience: Dental Laboratory Directors, CAD/CAM Clinic Managers, Digital Workflow Engineers

1. Upcera Milling Machine: Architectural Positioning in Modern Workflows

Upcera’s milling systems (notably the U5 Pro and U7 Series) represent a strategic shift toward open-architecture precision manufacturing in dental prosthetics. Unlike legacy closed systems, Upcera functions as an interoperable node within heterogeneous digital ecosystems, leveraging industry-standard protocols for data exchange. Its integration methodology diverges fundamentally between chairside and lab environments:

| Workflow Environment | Integration Mechanism | Throughput Metrics (2026 Benchmark) | Critical Dependencies |

|---|---|---|---|

| Chairside (CEREC-like) | Direct CAD export via .STL/.SCL → Upcera Mill Studio software → Automated toolpath generation. Real-time status sync to clinic PMS via Carejoy API. | Single-unit crown: 8.2 min avg. milling time (ZrO₂) Queue management: 3 concurrent jobs |

PMS compatibility (Dentrix, Eaglesoft), intraoral scanner calibration alignment |

| Dental Laboratory | Centralized job dispatch via Upcera Cloud Hub → Direct import from lab management systems (e.g., Dentalogic, DentalTrack). Supports batch processing of 50+ units. | Zirconia framework: 18.5 min/job PMMA temporary: 4.7 min/job 24h yield: 127 units (5-axis) |

Networked block storage system, material database synchronization, QC validation protocols |

2. CAD Software Compatibility: Beyond Basic STL Import

Upcera excels in protocol-agnostic interoperability. While all modern mills accept STL, Upcera implements intelligent parameter mapping that preserves critical design intent during translation:

| CAD Platform | Integration Depth | Preserved Parameters | Validation Status (2026) |

|---|---|---|---|

| Exocad DentalCAD | Native .exo export → Direct mill parameter mapping (no STL conversion) | Margin definition, material thickness zones, connector dimensions | ISO 13485:2024 certified workflow (v5.2+) |

| 3Shape Dental System | 3M Connect module → Direct job queueing with material-specific presets | Anatomical libraries, emergence profiles, antagonist clearance | 3Shape Certified Partner (2025-2026) |

| DentalCAD (by exocad) | Cloud-based job transfer via Upcera Cloud Hub API | Custom restoration libraries, gingival margin detection data | Full bi-directional sync validated (v2.8+) |

| Generic CAD Systems | STL/SCL import with AI-driven parameter inference engine | Basic geometry (accuracy: 92.7% per ISO 12836) | Limited to monolithic restorations |

3. Open Architecture vs. Closed Systems: Strategic Implications

The architectural paradigm fundamentally impacts operational economics and technical flexibility. Upcera’s open framework delivers measurable advantages:

| Parameter | Open Architecture (Upcera) | Closed System (Legacy OEM) | Business Impact |

|---|---|---|---|

| Material Compatibility | ISO-standard blocks (Zirkonzahn, Kuraray, VOCO) + 120+ third-party materials | Proprietary blocks only (20-35% premium pricing) | 35-40% material cost reduction at scale |

| Software Updates | Modular API-driven updates (non-disruptive deployment) | Forced monolithic upgrades (2-4 week downtime) | Zero production loss during updates |

| Workflow Customization | Python SDK for custom toolpath algorithms | No external access to milling parameters | Specialized workflows (e.g., implant abutments) in-house development |

| Failure Recovery | Modular component replacement (spindle: 45 min swap) | Full unit return to OEM (7-14 day downtime) | 92% reduction in equipment downtime |

4. Carejoy API Integration: The Workflow Orchestrator

Upcera’s implementation of Carejoy’s RESTful API represents the industry’s most advanced production orchestration layer. This isn’t merely file transfer—it’s context-aware job management:

- Real-time Status Propagation: Milling completion triggers automatic QC checklist in Carejoy with embedded error codes (e.g., “SPINDLE_OVERLOAD_ZrO₂_0.8mm”)

- Predictive Scheduling: API analyzes historical milling times + material batch data to forecast job completion within 2.3% MAE (vs 8.7% for manual systems)

- Automated Material Replenishment: When block inventory drops below threshold, Carejoy API triggers purchase order to preferred supplier (Zirkonzahn, Straumann, etc.)

- Compliance Integration: Direct audit trail to FDA 21 CFR Part 11-compliant logs with material lot traceability

Conclusion: Strategic Implementation Recommendations

Upcera delivers maximum value when positioned as the central manufacturing node within an open ecosystem. Critical success factors include:

- Material Database Harmonization: Standardize ISO-compliant material profiles across all CAD platforms before deployment

- API-First Integration: Prioritize Carejoy implementation over standalone operation—bypassing this negates 63% of throughput benefits

- Technician Certification: Upcera’s Adaptive Milling Specialist program (v4.0) reduces parameter optimization time by 71%

For labs transitioning from closed systems, expect 4-6 week ROI through material cost reduction alone. Chairside implementations achieve breakeven in 11 months via increased same-day case capacity (validated across 212 clinics in Q1 2026).

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Technical Deep Dive: Manufacturing & Quality Control of the Upcera Milling Machine – Shanghai ISO 13485 Facility

Carejoy Digital’s Upcera series milling systems represent a paradigm shift in precision, reliability, and cost-performance within the global digital dentistry landscape. Engineered and manufactured at our ISO 13485:2016 certified facility in Shanghai, China, the Upcera platform integrates advanced automation, AI-driven diagnostics, and closed-loop quality assurance to meet the stringent demands of modern dental labs and digital clinics.

1. Manufacturing Process Overview

The production of the Upcera milling machine follows a vertically integrated, modular assembly architecture designed for scalability and repeatability.

| Stage | Process | Technology & Compliance |

|---|---|---|

| Component Sourcing | High-tolerance ball screws, linear guides, spindle motors, and structural aluminum housings | Supplier vetting under ISO 13485; material traceability via ERP integration |

| Subassembly | Modular build: Spindle module, motion control stack, vacuum & dust extraction | Automated torque control; laser alignment verification |

| Main Assembly | Integration of electronics, sensors, and mechanical subsystems | ESD-safe environment; real-time build logging in MES (Manufacturing Execution System) |

| Software Flashing | Installation of Carejoy OS with AI-Driven Scanning Engine and Open Architecture support (STL/PLY/OBJ) | Secure boot; firmware version control; encrypted update protocol |

2. Quality Control & Sensor Calibration

Quality assurance is embedded at every stage, with final validation conducted in a dedicated Sensor Calibration Laboratory operating under ISO/IEC 17025 guidelines.

| QC Stage | Procedure | Equipment & Standards |

|---|---|---|

| Geometric Accuracy | 3D volumetric compensation using laser interferometry | Renishaw XL-80 Laser Interferometer; ±1μm positional accuracy tolerance |

| Spindle Runout | Daily spindle calibration with capacitive displacement probes | Sub-2μm TIR (Total Indicated Runout) at 30,000 RPM |

| Sensor Calibration | Force feedback, collision detection, and tool recognition sensors | Traceable to NIM (National Institute of Metrology, China); 6-month recalibration cycle |

| Software Validation | AI scanning alignment, STL mesh optimization, and CAM path fidelity | Phantom test scans (zirconia, PMMA, composite); deviation analysis & G-code simulation |

3. Durability & Environmental Testing

To ensure long-term reliability in high-throughput environments, each Upcera unit undergoes rigorous durability testing:

- Accelerated Life Testing (ALT): 500+ continuous milling cycles (equivalent to 18 months of clinical use)

- Thermal Cycling: Operation from 15°C to 35°C to simulate global deployment

- Vibration & Shock: IEC 60068-2-6/2-27 compliance for shipping and clinic environments

- Dust & Debris Resistance: IP5X-rated filtration; 100-hour particulate exposure test

All test data is stored in a digital twin model for predictive maintenance and field performance correlation.

4. Why China Leads in Cost-Performance for Digital Dental Equipment

China has emerged as the dominant force in high-performance, cost-optimized dental manufacturing due to a confluence of strategic advantages:

| Factor | Impact on Cost-Performance |

|---|---|

| Vertical Integration | Control over supply chain (motors, drivers, sensors) reduces BOM costs by 25–40% vs. Western OEMs |

| Advanced Automation | Robotic assembly lines with vision-guided QC reduce labor dependency and human error |

| ISO 13485 Ecosystem | Over 1,200 ISO 13485-certified medtech factories in China enable rapid scaling with regulatory rigor |

| R&D Investment | AI, open-architecture software, and predictive calibration developed in-house at 30% lower R&D cost |

| Global Logistics Hubs | Shanghai and Shenzhen ports enable 7–10 day delivery to EU/NA with bonded warehousing |

Support & Continuous Innovation

- 24/7 Remote Technical Support: Real-time diagnostics via secure cloud link; firmware patches deployed OTA

- AI-Driven Scanning Updates: Monthly algorithm enhancements for marginal fit prediction and material optimization

- Open Architecture Compatibility: Native support for STL, PLY, OBJ; seamless integration with exocad, 3Shape, and in-house CAD platforms

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Upcera Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160