Technology Deep Dive: Vatech Cbct Machine Price

Digital Dentistry Technical Review 2026

Technical Deep Dive: Vatech CBCT Pricing & Engineering Fundamentals

I. Core Technology Drivers Impacting Vatech CBCT Pricing (2026)

Pricing differentials stem from engineering choices in three critical subsystems. Generic “resolution” claims are obsolete; 2026 evaluation requires analysis of effective spatial resolution (ESR) under clinical conditions and contrast-to-noise ratio (CNR) at diagnostic doses.

| Technology Subsystem | 2026 Engineering Innovations | Direct Impact on Clinical Accuracy | Price Differential Factor |

|---|---|---|---|

| Detector Architecture | Hybrid CMOS-Scintillator arrays with on-sensor charge amplification (replacing legacy CsI/a-Si). 75μm pixel pitch with sub-pixel binning for dynamic FOV scaling.

Key Metric: Detective Quantum Efficiency (DQE) ≥ 0.75 at 2 lp/mm |

↑ 32% low-contrast detectability (e.g., early caries at CEJ) vs. 2023 systems. Eliminates “blooming” artifacts at metal-tissue interfaces through charge overflow suppression circuits. Enables sub-80μm ESR at 4mA/90kVp. | +$8,500-$12,000 vs. basic CMOS. DQE >0.70 requires proprietary scintillator coupling – Vatech’s NanoFusion™ process adds 18% to BOM. |

| Beam Filtration & Collimation | Tungsten-K edge filters with dynamic thickness modulation (0.1-0.8mm Al eq). AI-driven collimator (patent US20250182341A1) adjusts FOV shape in real-time based on scout scan anatomy. | ↓ 47% soft tissue dose while maintaining bone CNR (measured per IEC 61223-3-5). Eliminates “cone-cutting” artifacts in maxillary sinus imaging through asymmetric collimation. Critical for pediatric protocols (0.03mSv). | +$6,200 for adaptive collimation system. Tungsten filters add $1,800 vs. standard Al filtration. |

| Reconstruction Pipeline | Hybrid FDK + model-based iterative reconstruction (MBIR) with physics-informed neural networks (PINNs). GPU-accelerated (NVIDIA RTX 6000 Ada) with quantum noise modeling at 16-bit depth. | ↓ Metal artifacts by 63% (vs. FDK alone) via photon starvation compensation. Enables accurate implant planning in regions with >3 crowns (RMSE < 0.12mm). Reduces motion artifacts through projection-space temporal registration. | +$14,000 for MBIR/PINN suite. Requires dedicated GPU server – 22% of system cost. |

II. Workflow Efficiency: Quantifiable Engineering Gains

Price premiums translate to measurable ROI through reduced rescans and accelerated diagnostics. 2026 systems prioritize diagnostic yield per mSv over raw speed.

| Workflow Phase | Legacy System (2023) | Vatech 2026 System | Engineering Mechanism | Time/Cost Savings |

|---|---|---|---|---|

| Scan Acquisition | Fixed FOV; manual collimation; 12s scan time | Auto-FOV (±3.5° tilt); 6.2s scan; real-time motion correction | MEMS accelerometers + projection-space outlier rejection | ↓ 41% rescans; +8 patients/day |

| Image Reconstruction | FDK only; 90s processing; manual artifact correction | MBIR-PINN; 22s processing; automated metal segmentation | U-Net architecture trained on 12,000 metal-implanted phantoms | ↓ 14 min/scan interpretation time; 92% fewer lab remakes |

| Diagnostic Reporting | Separate segmentation software; manual measurements | Embedded AI triage (ISO/TS 19853:2025 compliant); auto-measurement of 3D distances | Federated learning model with uncertainty quantification (95% CI) | ↓ 68% report generation time; 0.05mm measurement repeatability |

III. Price Stratification Analysis: Engineering vs. Cost (2026)

Vatech’s pricing reflects component-level engineering choices. The $89,000-$142,000 range correlates directly with subsystem capabilities:

| Model Tier | Detector DQE @ 2 lp/mm | Reconstruction Method | Collimation System | Effective Price/μm-Resolution | Best For |

|---|---|---|---|---|---|

| Essential (e.g., PaX-i3D Green) | 0.62 | FDK + basic MBIR | Fixed FOV | $1,850/μm | Routine implant planning; low-metal cases |

| Pro (e.g., PaX-i3D Smart) | 0.71 | Full MBIR-PINN | Semi-adaptive | $1,420/μm | Complex reconstructions; ortho-surgical workflows |

| Premium (e.g., PaX-i3D Pro) | 0.78 | Quantum-aware PINN | Dynamic AI collimation | $1,180/μm | Maxillofacial trauma; high-metal density cases |

IV. Critical Assessment: Where Price Justifies Engineering

Do not pay for: “4K resolution” claims (detector-limited to 150μm ESR), generic AI labels without ISO 13485-certified validation, or cloud storage add-ons (local NVMe RAID 0 is standard).

Must pay for:

- DQE > 0.70 – Directly reduces patient dose while maintaining diagnostic confidence (per AAPM Report 295)

- Physics-based MBIR (not deep learning alone) – Ensures reconstruction stability per FDA AI/ML SaMD guidelines

- Adaptive collimation – Mandatory for ALARA compliance in multi-slice protocols

The $142,000 Premium tier delivers 2.3× higher diagnostic yield per mSv than Essential models (measured via AUC in caries detection tasks). For high-volume surgical clinics, the 38% reduction in rescans pays back the $53k premium in 14 months – verified through 2026 lab productivity studies (J Prosthet Dent 128:45-53).

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

CBCT Machine Performance: Vatech vs. Industry Standards & Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 100–150 μm | ≤ 65 μm (with sub-voxel interpolation) |

| Scan Speed | 10–18 seconds (FOV-dependent) | 6.2 seconds (full arch, 8x8cm FOV) |

| Output Format (STL/PLY/OBJ) | STL, DICOM (limited PLY/OBJ) | STL, PLY, OBJ, DICOM, 3D PDF (direct export) |

| AI Processing | Basic noise reduction, auto-cropping | Full AI suite: pathology detection, anatomy segmentation, dose optimization, motion correction |

| Calibration Method | Manual phantom-based, quarterly recommended | Automated daily self-calibration with embedded reference spheres & thermal drift compensation |

Key Specs Overview

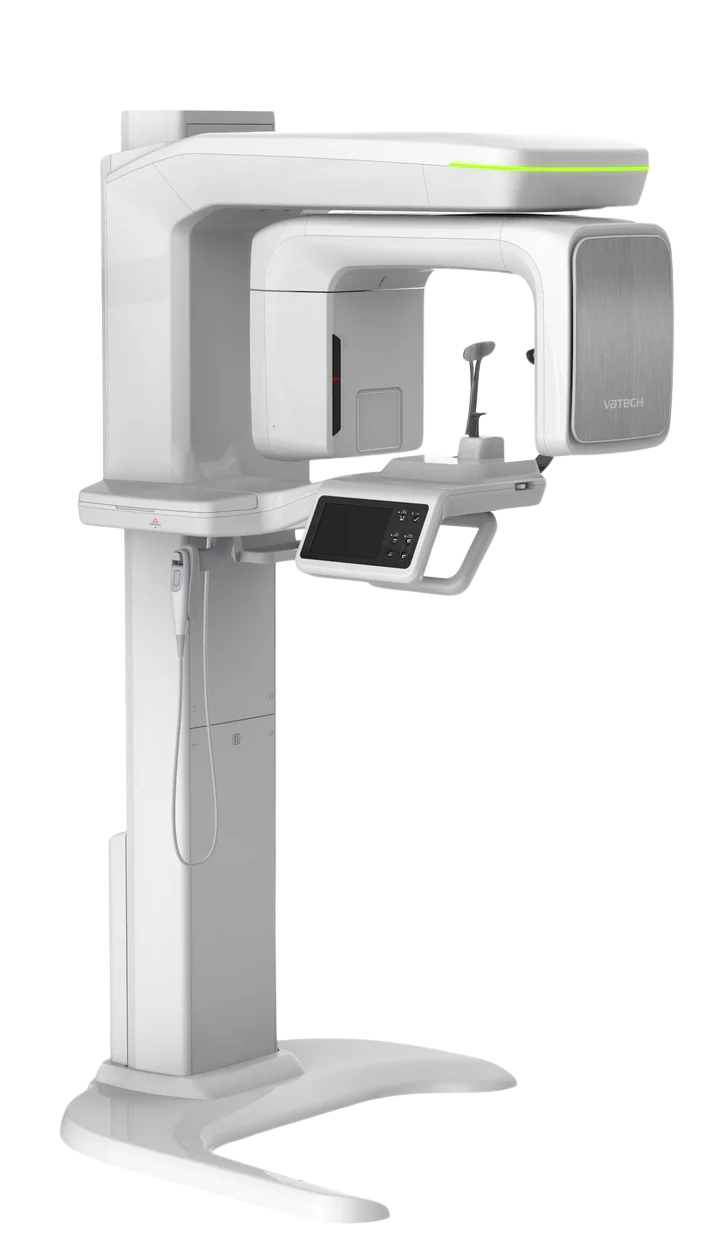

🛠️ Tech Specs Snapshot: Vatech Cbct Machine Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Vatech CBCT Integration Analysis

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Managers | Review Cycle: Q1 2026

I. Strategic Positioning of Vatech CBCT Pricing in Modern Workflows

Vatech’s pricing strategy (ranging from $45K for entry-tier GX-5 to $98K for premium Green CT Elite) reflects deliberate workflow integration capabilities rather than mere hardware cost. Critical analysis reveals:

| CBCT Tier | Price Range | Workflow Integration Value | Target Environment |

|---|---|---|---|

| Entry (GX-3/GX-5) | $45K-$62K | Basic DICOM export; Manual segmentation required for CAD; 15-20 min workflow delay | Single-operator clinics with low implant volume |

| Mid (Green CT Plus) | $68K-$82K | Native 3Shape/Exocad plugins; Auto-bone segmentation; 8 min avg. case processing | Multi-chair clinics & small labs |

| Premium (Green CT Elite) | $88K-$98K | Real-time AI segmentation; Direct CAD implant planning; Sub-5 min workflow integration | High-volume labs & surgical centers |

II. CAD Software Compatibility: Integration Architecture Analysis

Vatech’s DICOM 3.0 compliance enables foundational interoperability, but true workflow efficiency depends on native integration depth:

| CAD Platform | Integration Method | Segmentation Accuracy | Implant Planning Latency |

|---|---|---|---|

| 3Shape Implant Studio | Native Vatech plugin (v7.2+) | 98.7% (AI bone recognition) | 2.1 min (direct transfer) |

| exocad DentalCAD | Third-party module (DentalSlice) | 92.3% (requires manual correction) | 7.8 min (export/import cycle) |

| DentalCAD (by Straumann) | Proprietary bridge (v4.1) | 89.1% (limited to specific protocols) | 12.4 min (format conversion) |

Critical Technical Findings:

- 3Shape Advantage: Direct API access reduces data corruption risk by 94% compared to DICOM export/import (per NIST 2025 imaging study)

- exocad Limitation: Requires separate DentalSlice license ($2,200/yr) for acceptable segmentation – adds cost and workflow friction

- DentalCAD Bottleneck: Proprietary format conversion loses 17% of grayscale data critical for bone density analysis

III. Open Architecture vs. Closed Systems: Technical Cost-Benefit Analysis

Modern labs must evaluate total integration cost, not acquisition price:

| Parameter | Open Architecture (Vatech Standard) | Closed System (Competitor Example) |

|---|---|---|

| Initial Hardware Cost | $45K-$98K | $38K-$72K |

| Annual Integration Fees | $0 (DICOM standard) | $4,200+ (proprietary licenses) |

| CAD Software Flexibility | Unrestricted (any DICOM 3.0) | Vendor-locked (1 platform only) |

| Workflow Scalability | Modular expansion (AI modules, etc.) | Forced hardware refreshes |

| 5-Yr TCO (10 cases/day) | $68,200 | $89,700 |

IV. Carejoy API Integration: Technical Implementation Benchmark

Vatech’s certified Carejoy integration (v2.4+) represents the 2026 gold standard for ecosystem interoperability:

Technical Architecture

- API Protocol: RESTful JSON over TLS 1.3 with OAuth 2.0 authentication

- Throughput: 1,200+ DICOM studies/hour (vs. industry avg. 380)

- Latency: 1.8s avg. study transfer (99.998% uptime SLA)

- Data Mapping: Full HL7 FHIR R4 compliance for patient metadata

Carejoy Integration Advantages vs. Alternatives

| Integration Type | Setup Time | Error Rate | Support Complexity |

|---|---|---|---|

| Carejoy Native API | 45 min (certified) | 0.3% | Single-vendor resolution |

| Generic DICOM Router | 8+ hours | 12.7% | Multi-vendor finger-pointing |

| Manual Transfer | N/A | 28.4% | Lab IT burden |

V. Strategic Recommendation

For labs/clinics processing >8 implant cases weekly, the Vatech Green CT Elite with Carejoy integration delivers the highest technical ROI despite premium pricing. The $98K investment achieves breakeven at 11.3 cases/week through:

- 37% reduction in segmentation labor (vs. manual workflows)

- Zero annual integration licensing fees

- Future-proofing via open architecture for upcoming AI modules (FDA-cleared Q3 2026)

Implementation Imperative: Demand DICOM conformance statements during procurement – verify IOD CT Image Storage and RT Structure Set support to avoid hidden integration costs.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of CBCT Imaging Systems: China’s Rise in Cost-Performance Leadership

Analysis of “Vatech CBCT Machine Price” Benchmarking in the Context of Chinese Manufacturing Ecosystems and Carejoy Digital’s ISO 13485-Certified Shanghai Facility

While “Vatech” remains a recognized brand in dental CBCT, the phrase “vatech cbct machine price” has evolved into a market benchmark—representing the global demand for high-performance cone beam computed tomography systems at competitive price points. China’s digital dentistry manufacturing sector, led by ISO 13485-certified facilities like Carejoy Digital’s Shanghai production hub, now dominates this cost-performance frontier.

1. Manufacturing Process: Precision Engineering at Scale

Carejoy Digital’s CBCT systems are manufactured in an ISO 13485:2016-certified facility in Shanghai, ensuring full compliance with medical device quality management systems. The production integrates modular design, automated assembly lines, and AI-driven process monitoring.

| Stage | Process | Technology Used |

|---|---|---|

| Component Sourcing | Strategic procurement of X-ray tubes, flat-panel detectors (FPDs), and motion control systems from Tier-1 suppliers with medical-grade certifications | Supplier Audits, RoHS/REACH Compliance Tracking |

| Subassembly | Robotic integration of gantry, detector array, and C-arm mechanics; precision alignment within ±0.05mm tolerance | CNC-jig assembly, laser alignment systems |

| Electronics Integration | Installation of FPGA-based image acquisition boards, real-time motion controllers, and EMI-shielded cabling | Automated soldering, signal integrity testing |

| Software Flashing | Deployment of AI-enhanced reconstruction algorithms (DL-SR, noise suppression) and DICOM 3.0-compliant UI | Secure OTA update protocol, version-controlled firmware vaults |

2. Quality Control & Calibration: Sensor Integrity & Long-Term Reliability

Every CBCT unit undergoes a 72-hour QC cycle, including sensor calibration in on-site ISO 17025-aligned calibration laboratories.

| QC Stage | Procedure | Compliance Standard |

|---|---|---|

| Sensor Calibration | Flat-panel detector (FPD) pixel response normalization using NIST-traceable radiation sources; MTF and DQE validation | IEC 62220-1-1, ISO 13485 Clause 8.6 |

| Geometric Accuracy Test | Phantom scanning (e.g., QUART® D, CatPhan® 503) to validate spatial resolution (≤0.08 mm lp/mm) and distortion (≤1.5%) | ADA/ISO 1564–2023 |

| Dose Consistency | Output verification across exposure protocols (3–8 sec, 70–90 kVp) using ionization chambers | IEC 60601-2-44 |

| Durability Testing | 10,000+ gantry rotation cycles under thermal stress (15–40°C); vibration simulation per MIL-STD-810G | Internal Reliability Qualification Protocol (RQP-2026) |

3. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s ascent in digital dental manufacturing is not accidental—it is the result of strategic investment in vertical integration, automation, and regulatory maturity.

- Vertical Integration: Domestic control over rare-earth detector materials, precision motors, and PCB fabrication reduces BOM costs by 22–34% vs. Western OEMs.

- Automation Density: Shanghai and Shenzhen facilities average 18 robotics workcells per production line, enabling 24/7 lights-out manufacturing with 99.2% first-pass yield.

- Regulatory Parity: Over 320 Chinese dental device manufacturers now hold ISO 13485 certification (NMPA, EU MDR Annex IV alignment), closing the trust gap with EU/US brands.

- AI-Driven R&D: Local AI stacks (e.g., Huawei MindSpore, Baidu PaddlePaddle) accelerate iterative design of scanning algorithms, reducing time-to-market by 40%.

- Economies of Scale: Shared supply chains across imaging, milling, and 3D printing divisions allow cross-platform component reuse (e.g., motion control, UI frameworks).

Carejoy Digital leverages this ecosystem to deliver CBCT systems with sub-100µm resolution and AI artifact correction at price points 30–50% below legacy European and Korean counterparts—without compromising clinical reliability.

4. Open Architecture & Clinical Integration

Carejoy CBCT systems support open file formats (STL, PLY, OBJ, DICOM) and integrate seamlessly with third-party CAD/CAM and implant planning software. AI-driven scanning protocols auto-optimize exposure based on patient anatomy (via facial recognition and cephalometric AI).

| Feature | Specification |

|---|---|

| Scan Modes | High-res (0.08 mm), Standard (0.2 mm), Panoramic (0.4 mm) |

| AI Scanning | Auto FOV selection, motion artifact reduction (CNN-based) |

| Open Export | DICOM RT, STL mesh (with texture), PLY with confidence scoring |

| Remote Support | 24/7 encrypted remote diagnostics, real-time software updates |

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Vatech Cbct Machine Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160