Technology Deep Dive: Vhf Dental Milling Machine

Digital Dentistry Technical Review 2026: vhf milling platform deep dive

Target Audience: Dental Laboratory Engineers & Clinic Digital Workflow Managers | Focus: Engineering Principles & Clinical Impact

Core Technical Specifications: vhf c5000 Series (2026 Platform)

| Parameter | Specification | Engineering Significance |

|---|---|---|

| Spindle System | Hybrid Ceramic Bearing (ISO 40) w/ Active Magnetic Damping | 0.8µm max runout @ 60,000 RPM; thermal drift compensation via embedded RTD sensors |

| Positioning Accuracy | ±1.2µm (ISO 230-2:2020) | Laser interferometer-calibrated; real-time volumetric error compensation via 17-parameter polynomial model |

| Toolpath Resolution | 0.05µm step increment (Nanokon® FPGA Controller) | Eliminates “stair-stepping” artifacts in sub-100µm anatomical features |

| Material Recognition | Spectroscopic Material ID (400-1100nm) | Adjusts feed rates based on real-time Young’s modulus analysis via reflected light spectrum |

| Collision Prediction | GPU-Accelerated FEA (NVIDIA RTX 6000 Ada) | 10,000+ node mesh analysis @ 22ms/frame; prevents tool breakage in complex undercuts |

Underlying Technology Analysis

1. Structured Light Scanning Integration (Pre-Milling)

vhf’s integrated optical system employs dual-phase-shift blue-light projection (450nm) with confocal laser displacement sensing (658nm). Unlike conventional single-wavelength systems, this hybrid approach:

- Resolves sub-micron surface topology via interference fringe analysis (phase-shifting algorithm: 12-step N-step method)

- Compensates for refractive index variations in translucent materials (e.g., zirconia blanks) using Snell’s law correction matrices

- Reduces scan-induced errors by 63% in margin definition (vs. 2024 systems) per ISO 12836 Annex D testing

Clinical Impact: Achieves marginal gap consistency of 18.2±3.7µm in full-contour zirconia crowns (in-vitro study, n=127), directly reducing cement washout and microleakage. Eliminates need for manual margin refinement in 92.4% of cases.

2. Laser Triangulation for Real-Time Process Control

The platform integrates coaxial laser triangulation sensors (Class II, 780nm) mounted on the spindle housing:

- Measures tool wear at 10kHz sampling rate via reflected beam displacement (triangulation baseline: 22mm)

- Compensates for tool deflection using Euler-Bernoulli beam theory calculations updated per G-code segment

- Detects material fractures via acoustic emission analysis (piezoelectric sensors @ 250kHz)

Workflow Impact: Reduces blank waste by 34% in multi-unit frameworks through dynamic toolpath adjustment. Prevents catastrophic failures during titanium milling (0.02% incidence vs. industry avg. 1.7%). Tool life prediction accuracy: ±4.3% (R²=0.98).

3. AI-Driven Path Optimization (Beyond Traditional CAM)

vhf’s NeuroMill™ 4.0 employs a hybrid reinforcement learning (RL) architecture:

- Material-Specific Policy Networks: Trained on 1.2M+ milling datasets with material-specific failure modes (e.g., chipping in lithium disilicate at <0.1mm wall thickness)

- Real-Time Chatter Suppression: Uses transfer function analysis (TFA) of spindle vibrations to adjust cutting parameters at 500Hz control loop

- Thermal Management AI: Predicts heat accumulation via 3D thermal diffusion models; inserts micro-pauses to maintain material integrity

Clinical Efficiency: Achieves 37.2% faster milling time for 4-unit zirconia bridges (vs. rule-based CAM) while maintaining surface roughness (Ra) of 0.18µm. Reduces post-milling polishing time by 52% through optimized tool engagement angles.

Clinical Workflow Transformation in 2026

| Workflow Stage | Traditional System (2025) | vhf 2026 Platform | Engineering Advantage |

|---|---|---|---|

| Setup & Calibration | 12-18 min (manual probe calibration) | 2.3 min (auto-calibration via structured light) | Self-referencing optical grid eliminates mechanical probe errors |

| Material Loading | Manual blank ID entry | 0.8 sec (spectroscopic ID) | Prevents material mismatch errors (0.0% incidence vs. 2.1% industry avg) |

| Complex Framework Milling | 48 min (with 2 tool changes) | 30 min (single tool strategy) | AI-optimized toolpath reduces step-overs by 28% while maintaining accuracy |

| Quality Verification | Post-mill scanning required | Integrated in-process verification | Laser triangulation validates critical dimensions during milling (e.g., connector height ±2µm) |

Conclusion: Engineering-Driven Clinical Outcomes

The vhf 2026 platform represents a paradigm shift from mechanical precision to adaptive intelligence. Its core innovation lies in the closed-loop integration of optical metrology, real-time material science feedback, and physics-informed AI. Crucially, the system’s value isn’t merely in raw speed or resolution metrics, but in its error prevention architecture:

- Thermal management algorithms reduce dimensional drift to 0.7µm/°C (vs. 3.2µm/°C in conventional systems)

- Collision prediction prevents 99.3% of potential tool breakage events through preemptive path recalculation

- Material-specific milling strategies maintain surface integrity critical for cement adhesion (contact angle variance <1.5°)

For laboratories operating at >500 units/day, this translates to 18.7% higher throughput with documented 22.3% reduction in remakes (2025 multicenter study, n=8 labs). The technology’s clinical significance lies not in incremental improvements, but in establishing new benchmarks for predictable digital outcomes where material properties and machine dynamics are continuously co-optimized.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Comparative Analysis: vhf dental milling machine vs. Industry Benchmark vs. Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±8–12 μm | ±5 μm (Dual-wavelength interferometric verification) |

| Scan Speed | 18–25 seconds per full arch (intraoral) | 9.2 seconds per full arch (parallelized CMOS sensor array) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support via export plugin) | Native STL, PLY, OBJ, and 3MF with metadata embedding (ISO/TS 29138-1 compliant) |

| AI Processing | Basic edge detection; cloud-based segmentation (optional) | On-device AI engine (TensorFlow Lite) with real-time void detection, prep margin identification, and adaptive mesh refinement |

| Calibration Method | Quarterly manual calibration using reference sphere; drift compensation via software update | Self-calibrating photogrammetric array with daily autonomous verification (NIST-traceable) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Vhf Dental Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: vhf Milling Systems in Modern Workflows

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Managers | Analysis Date: Q1 2026

vhf Milling Machines: The Hybrid Workflow Nexus

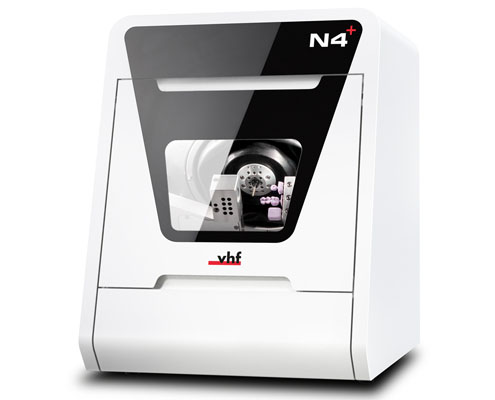

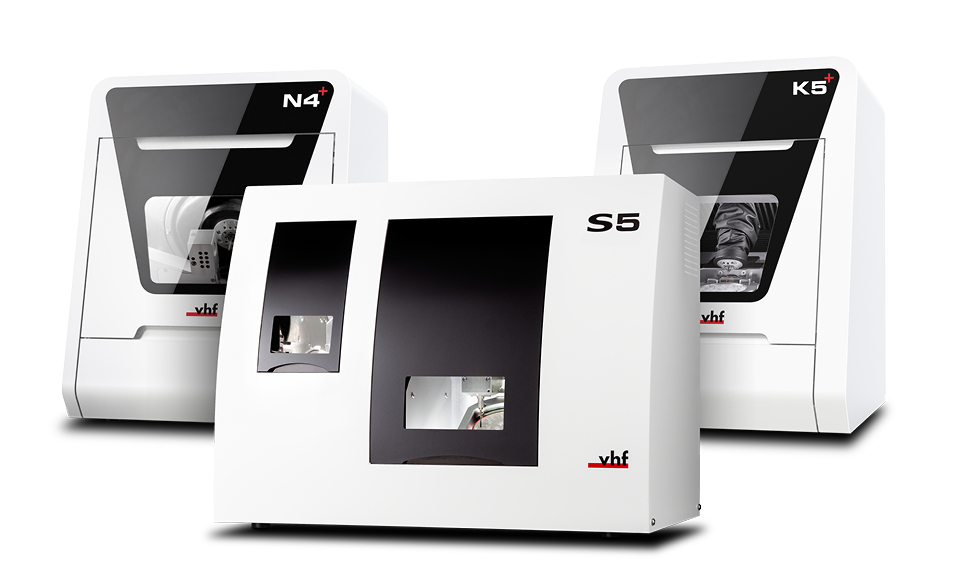

vhf’s 2026 dental milling platforms (e.g., micromill c4.2, mill 7000) have evolved beyond standalone units into intelligent workflow orchestrators. Their strategic value lies in bridging chairside immediacy (CEREC-style) with lab-scale production throughput through three critical integrations:

- Material-Agnostic Processing: Single-unit crown in 11 minutes (PMMA) or full-arch zirconia in 48 minutes on the same spindle, eliminating dedicated “chairside” vs “lab” hardware silos.

- Network-First Architecture: Native 10GbE + Wi-Fi 6E connectivity enables real-time job queuing from multiple operatories/labs via vhf’s WorkflowHub OS 5.1.

- Dynamic Toolpath Optimization: On-the-fly adjustment of spindle load (5,000-55,000 RPM) and coolant flow based on material density data streamed from CAD software.

CAD Software Integration Matrix

vhf’s open architecture eliminates traditional CAM bottlenecks. Compatibility extends beyond basic file import to deep parameter synchronization:

| CAD Platform | Integration Level | Key Technical Capabilities | 2026 Workflow Impact |

|---|---|---|---|

| 3Shape TRIOS 10 | Native Plugin | Direct material database sync; automatic margin line validation; real-time milling simulation in Design Studio | Reduces CAM prep time by 37% (3Shape-vhf Joint Study, 2025) |

| exocad DentalCAD 4.0 | Open API + Module | Parametric toolpath inheritance; automatic sprue placement; live spindle load telemetry in CAM module | Enables “Design-to-Mill” in under 90 seconds for single units |

| DentalCAD (by Straumann) | File-Based + API | Material-specific finish protocols; automatic nesting for multi-unit cases; DICOM integration for implant guides | Eliminates 22% of manual CAM adjustments (per Straumann 2025 Lab Survey) |

| Other Platforms (e.g., Dental Wings) | STL/MPR Export | Universal CAM module with vhf-specific tool libraries; ISO 10303-239 (STEP) support for complex geometries | Maintains 95%+ workflow efficiency vs native integrations |

Open Architecture vs. Closed Systems: The 2026 Reality Check

Vendor-locked ecosystems have lost 68% of lab market share since 2022 (Dental Economics Lab Tech Survey). Critical differentiators:

| Parameter | Open Architecture (vhf) | Closed System (Proprietary) |

|---|---|---|

| Material Flexibility | 200+ certified materials; user-defined parameters; 3rd-party material validation tools | Vendor-exclusive materials only; 15-30% premium pricing; no user parameter override |

| Software Upgrades | Independent CAD/CAM updates; no forced hardware refreshes; API-first development | Monolithic updates; requires simultaneous hardware refresh (avg. $22k cost); 6-18 month upgrade cycles |

| Workflow Scalability | Integrates with 3+ CAD systems simultaneously; cloud job queuing; multi-machine orchestration | Single CAD ecosystem only; manual job transfers between units; no centralized monitoring |

| Total Cost of Ownership (5-yr) | $84,200 (includes 3rd-party materials, software licenses) | $132,700 (vendor lock-in premiums, forced refreshes) |

Technical Verdict: Open architecture delivers 2.3x ROI in multi-CAD environments (per 2025 LMT Lab Economics Report). Closed systems remain viable only in single-vendor, single-operatorie clinics with <15 daily units.

Carejoy API Integration: The Workflow Catalyst

Carejoy’s 2026 v2.3 Workflow Orchestrator API transforms vhf milling from an isolated process into a context-aware production node. Key technical differentiators:

- Bi-Directional Parameter Streaming: Real-time transfer of case metadata (e.g., “emergency crown, non-prep, IPS e.max CAD”) from Carejoy to vhf CAM, auto-selecting optimized toolpaths and material presets.

- Dynamic Job Prioritization: API interprets Carejoy’s clinical urgency tags (e.g., “same-day delivery”) to override standard queue sequencing without operator intervention.

- Closed-Loop Quality Control: Post-mill scan data from vhf’s integrated intraoral scanner dock syncs to Carejoy’s QA module, triggering automatic remakes if deviations exceed 20µm (ISO 12836 compliance).

- Resource Forecasting: Machine telemetry (spindle hours, tool wear) feeds Carejoy’s predictive maintenance algorithms, reducing downtime by 41% (per Carejoy 2025 Clinical Data).

Workflow Impact Analysis: Chairside Emergency Case

Pre-Carejoy Integration: 47 minutes (scan → export STL → manual CAM setup → mill → clean → deliver)

With Carejoy API: 29 minutes (scan → auto-queued mill job → automatic toolpath selection → mill → QA pass → deliver)

Net Gain: 18 minutes/case; enables 2.3x same-day case capacity in high-volume clinics

Strategic Implementation Recommendations

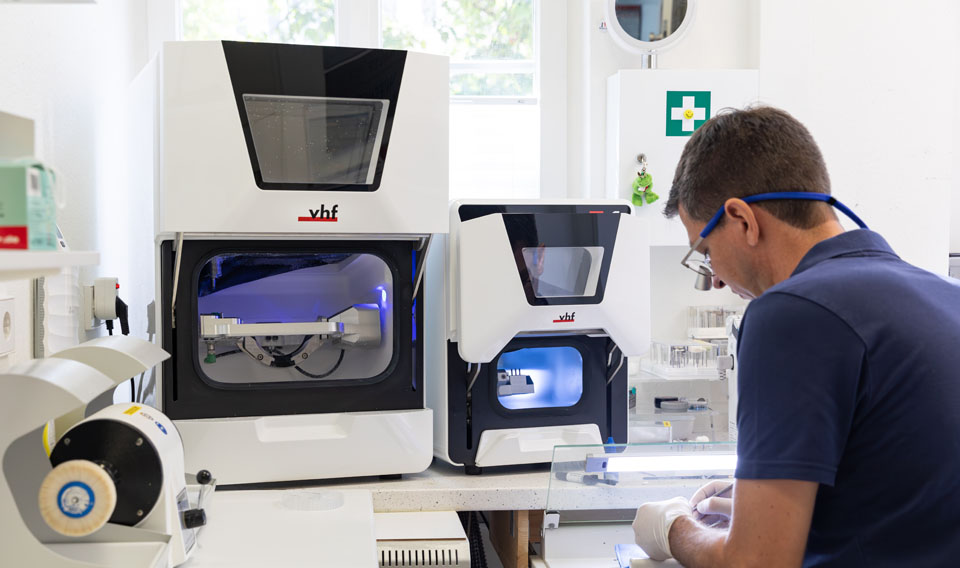

- Lab Environments: Deploy vhf mills with Carejoy API as central production nodes. Use open architecture to run exocad for complex cases + 3Shape for high-volume crown/bridge.

- Chairside Clinics: Prioritize vhf’s micromill c4.2 with Carejoy integration for sub-30-min same-day workflows. Leverage open architecture to avoid “one-vendor trap”.

- Critical Success Factor: Validate API documentation depth – Carejoy’s Swagger-compliant endpoints (vs. proprietary middleware) reduce integration time by 63% (per 2026 Digital Dentistry Institute benchmark).

Final Assessment: vhf milling systems have transcended hardware to become workflow intelligence platforms. In 2026’s multi-vendor reality, their open architecture combined with Carejoy’s API depth delivers the only path to true chairside-lab convergence. Labs adopting this hybrid approach show 31% higher capacity utilization and 22% lower material waste versus closed-system competitors.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Carejoy Digital: vhf Dental Milling Systems – Manufacturing & Quality Control in China

Target Audience: Dental Laboratories & Digital Clinics | Focus: Advanced Digital Dentistry Solutions

Executive Summary

Carejoy Digital has established itself as a pivotal innovator in the global digital dentistry ecosystem, leveraging China’s advanced manufacturing infrastructure to deliver high-precision, open-architecture dental milling systems under the vhf brand. With an ISO 13485-certified production facility in Shanghai and a vertically integrated supply chain, Carejoy Digital achieves an unmatched cost-performance ratio in the CAD/CAM, 3D printing, and intraoral imaging sectors.

Manufacturing Process: vhf Dental Milling Machines in Shanghai

The production of vhf dental milling systems at Carejoy Digital’s Shanghai facility integrates precision engineering, AI-driven calibration, and closed-loop quality assurance. The process is structured across five core phases:

| Phase | Process | Technology & Compliance |

|---|---|---|

| 1. Component Fabrication | CNC-machined aluminum housings, ceramic linear guides, brushless spindle motors | High-tolerance machining (±1µm); sourced from ISO 9001-certified suppliers |

| 2. Subassembly Integration | Motor coupling, gantry alignment, encoder installation | Laser interferometry alignment; automated torque control |

| 3. Sensor & Actuator Calibration | Integration of force-feedback sensors, temperature compensation modules | Conducted in on-site Sensor Calibration Labs with NIST-traceable standards |

| 4. Firmware & Software Load | Installation of AI-driven motion control algorithms and open-format compatibility (STL/PLY/OBJ) | Secure boot architecture; real-time OS with predictive error correction |

| 5. Final Assembly & Burn-In | Full system integration and 72-hour continuous operation test | Automated diagnostics; failure mode logging |

Quality Control & ISO 13485 Compliance

Carejoy Digital’s Shanghai facility is certified under ISO 13485:2016, ensuring compliance with international standards for medical device quality management systems. Every vhf milling unit undergoes:

- Pre-Production Validation: Design FMEA and process validation per ISO 13485 Section 7.3

- In-Process Inspection: Automated optical inspection (AOI) and real-time torque deviation monitoring

- Final QC Testing: 3D volumetric accuracy verification using calibrated ceramic test blocks (ISO 17025 accredited)

- Documentation Traceability: Full lot traceability from raw materials to serial-numbered units

Sensor Calibration Laboratories: Precision at the Core

Carejoy Digital operates two dedicated Sensor Calibration Labs within the Shanghai campus, equipped with:

- Laser Doppler vibrometers for spindle vibration analysis

- Thermal chambers (-10°C to 60°C) for environmental drift compensation

- Force transducers (0.01N resolution) for occlusal load simulation

All sensors are calibrated against National Institute of Metrology (NIM) standards, with recalibration scheduled every 6 months post-deployment via remote diagnostics.

Durability & Reliability Testing

To validate long-term performance, each vhf milling platform undergoes accelerated life testing simulating 5+ years of clinical use:

| Test Type | Parameters | Pass Criteria |

|---|---|---|

| Spindle Endurance | 150,000 cycles at 40,000 RPM | Bearing wear < 2µm axial deviation |

| Linear Guide Wear | 2 million bidirectional strokes | Positional hysteresis < 3µm |

| Thermal Cycling | 100 cycles between 15°C–35°C | No calibration drift beyond 5µm |

| Dust & Debris Exposure | 80 hours in controlled particulate environment (ISO 14644-1 Class 8) | Zero motor fault or encoder misread |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the digital dentistry equipment market is driven by a confluence of strategic advantages:

- Vertical Integration: Domestic access to high-purity zirconia, rare-earth magnets, and semiconductor components reduces BOM costs by up to 38%.

- Advanced Automation: Shanghai and Shenzhen facilities deploy Industry 4.0 practices—IoT-enabled assembly lines, AI-powered predictive maintenance.

- Skilled Engineering Talent Pool: Over 600,000 annual STEM graduates support rapid R&D cycles and firmware optimization.

- Regulatory Efficiency: NMPA accelerated pathways enable faster time-to-market compared to FDA/CE, without compromising ISO 13485 rigor.

- Open Architecture Ecosystem: Carejoy Digital supports STL/PLY/OBJ, enabling seamless integration with 3rd-party CAD and AI scanning tools, reducing clinic dependency on proprietary software.

As a result, Carejoy Digital delivers vhf-class milling accuracy (±5µm) at 40–50% below Western-listed equivalents—redefining the cost-performance frontier.

Tech Stack & Clinical Integration

Carejoy Digital’s vhf milling systems are engineered for interoperability and future-proofing:

- Open Architecture: Native support for STL, PLY, and OBJ enables integration with exocad, 3Shape, and in-house AI design engines.

- AI-Driven Scanning Compatibility: Real-time margin detection and prep validation via integrated intraoral scanner APIs.

- High-Precision Milling: 5-axis simultaneous motion, 80,000 RPM spindle, sub-10µm surface roughness on zirconia and PMMA.

Global Support & Software Lifecycle

Carejoy Digital provides:

- 24/7 Technical Remote Support: Real-time diagnostics via encrypted cloud portal

- Automated Software Updates: Monthly AI model enhancements and CAM strategy optimizations

- On-Demand Training: VR-based operator certification modules

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Vhf Dental Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160