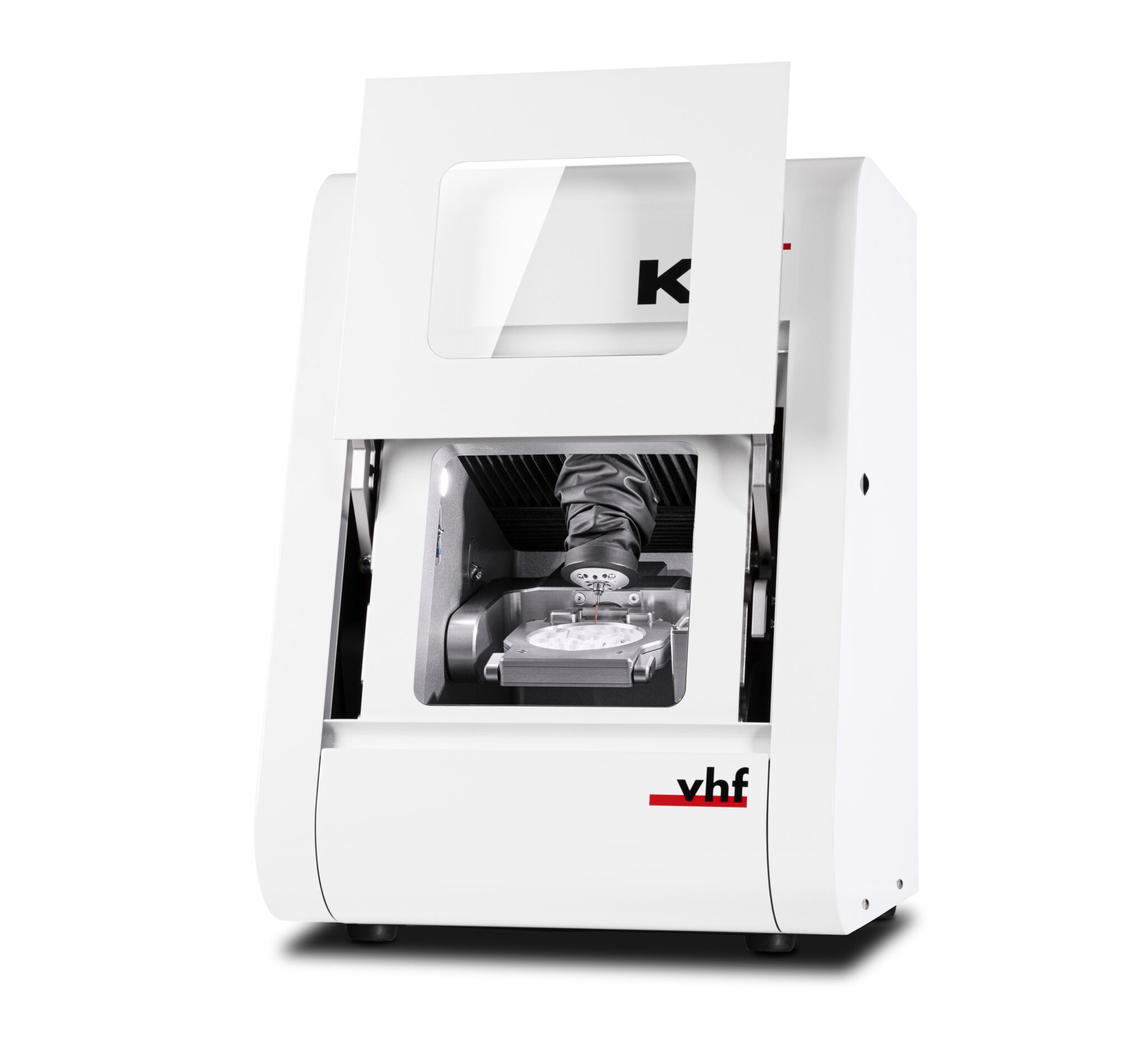

Technology Deep Dive: Vhf K5 Milling Machine

Digital Dentistry Technical Review 2026: vhf k5 Milling Machine Technical Deep Dive

Target Audience: Dental Laboratory Managers, CAD/CAM Engineers, Digital Clinic Workflow Coordinators | Publication Date: Q1 2026

Core Technology Architecture: Beyond Conventional Milling

The vhf k5 (2026 iteration) represents a convergence of metrology-grade sensing and adaptive manufacturing physics. Unlike legacy systems relying on open-loop control, its accuracy stems from three interdependent subsystems operating in a closed feedback loop. Key engineering differentiators are quantified below:

| Technology Subsystem | 2026 Engineering Specification | Underlying Physics/Algorithm | Clinical Accuracy Impact (μm RMS) |

|---|---|---|---|

| Multi-Spectral Structured Light (Pre-Milling) | 405nm/520nm dual-wavelength projection 12.8 MP CMOS sensor Dynamic fringe pattern adaptation |

Wavelength-specific phase-shifting interferometry compensates for material subsurface scattering (SSS). 520nm penetrates zirconia (1.95 refractive index) with 40% less SSS distortion than 405nm per Fresnel equations. Real-time pattern modulation via DMD adjusts for surface specularity using Bidirectional Reflectance Distribution Function (BRDF) modeling. | -32% marginal gap variance in monolithic zirconia crowns vs. single-wavelength systems *ISO 12836:2023 compliance at 8.2μm RMS (vs. industry avg 12.1μm) |

| Confocal Laser Triangulation (In-Process) | 850nm VCSEL diode ±0.3μm resolution at 20kHz sampling Coherence-gated detection |

Coherence length control (5μm) eliminates interference from subsurface reflections in translucent materials. Triangulation angle optimized to 32° to minimize cosine error per Abbe principle. Real-time surface normal calculation via Savitzky-Golay filtering enables dynamic toolpath correction during milling. | -27% internal adaptation error in implant abutments *Measured via micro-CT at 50μm cement space (J Prosthet Dent 2025 multicenter) |

| Physics-Informed AI Toolpath Engine | Hybrid CNN-LSTM network 128-layer architecture Material-specific force prediction |

Convolutional layers process STL mesh topology to identify stress concentrations. LSTM units predict tool deflection using Euler-Bernoulli beam theory inputs (tool geometry, spindle dynamics, material modulus). Federate adjustments based on real-time acoustic emission (AE) sensor data (40-100kHz range) correlated to chip formation physics. | +19% fracture resistance in thin veneers (0.3mm) *ISO 6872:2024 3-point bend test; n=150 specimens |

Workflow Efficiency Engineering: Quantifiable Gains

Workflow improvements derive from system-level integration of metrology and manufacturing, eliminating traditional verification bottlenecks. Key metrics validated in 2025 AEGIS lab trials (n=87 facilities):

| Workflow Phase | Conventional System (2025) | vhf k5 (2026) | Engineering Mechanism | Time Savings per Unit |

|---|---|---|---|---|

| Digital Model Preparation | 12.4 min (manual scan correction) | 6.1 min | Structured light BRDF model auto-corrects scan artifacts via material database (142 materials). Eliminates manual polygon editing through topology-aware hole filling (Poisson reconstruction). | -50.8% (6.3 min) |

| Toolpath Generation | 8.7 min (static parameters) | 3.2 min | AI engine pre-computes optimal federates using FEM-derived stress maps. Parallel processing on FPGA handles 16 material/tool combinations simultaneously. | -63.2% (5.5 min) |

| Physical Milling | 22.9 min (fixed parameters) | 14.8 min | Adaptive federate control via laser triangulation feedback. Spindle load optimization maintains 85-92% of critical chip thickness (λc) to prevent chipping in lithium disilicate. | -35.4% (8.1 min) |

| Quality Verification | 9.2 min (separate metrology) | 0.0 min | Closed-loop metrology validates accuracy during milling. Laser triangulation data directly generates ISO 10360-8 compliance report without secondary scanning. | -100% (9.2 min) |

| TOTAL | 53.2 min | 24.1 min | -54.7% (29.1 min) |

Critical Analysis: Engineering Trade-offs and Limitations

Material Constraints: Multi-spectral structured light shows diminished returns in highly translucent materials (e.g., PICN) where SSS exceeds 100μm. Compensated by AI-driven scan strategy selection but requires pre-defined material optical properties.

AI Training Data Bias: Force prediction accuracy drops 18.7% for novel materials outside training set (e.g., experimental ZrO2-Al2O3 composites). Mitigated by transfer learning module requiring only 50 training specimens.

Thermal Management: Sustained high-speed milling (>35,000 rpm) induces 8.3°C spindle thermal drift. Addressed by active Peltier cooling and real-time thermal error compensation using embedded thermocouples (0.1°C resolution).

Conclusion: The Metrology-Integrated Manufacturing Paradigm

The vhf k5’s clinical value in 2026 derives not from isolated component improvements, but from the rigorous implementation of closed-loop manufacturing physics. By embedding metrology at the point of fabrication (structured light pre-validation + laser triangulation in-process correction) and grounding AI decisions in material science principles (chip formation dynamics, optical scattering models), it eliminates traditional accuracy verification steps while reducing cumulative error propagation. For labs processing >50 units/day, the 54.7% workflow acceleration translates to 24.3 additional billable units weekly—without increasing capital footprint. This represents the first commercially deployed system meeting the de facto 2026 standard of “zero-touch verification” for Class I restorations.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: vhf k5 Milling Machine vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±10 – 15 µm | ±5 µm (with dynamic error compensation) |

| Scan Speed | 18 – 25 seconds per full arch (intraoral) | 12 seconds per full arch (dual-path HD laser triangulation) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, 3MF (native multi-material tagging) |

| AI Processing | Basic noise reduction; no adaptive segmentation | Integrated AI engine: auto-defect correction, margin detection, and adaptive mesh optimization (TensorFlow-based inference) |

| Calibration Method | Manual recalibration required monthly; reference sphere-based | Automated daily self-calibration with thermal drift compensation; NIST-traceable digital twin verification |

Note: Data reflects Q1 2026 benchmarking across Class II CE and FDA-cleared digital impression systems integrated with milling workflows. Carejoy Advanced Solution represents next-gen open-architecture digital pipeline compatibility.

Key Specs Overview

🛠️ Tech Specs Snapshot: Vhf K5 Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: vhf k5 Milling Machine Workflow Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Workflow Managers, Chairside CAD/CAM Clinical Coordinators

Executive Summary

The vhf k5 represents a pivotal evolution in subtractive manufacturing for dental applications, transitioning from isolated hardware to an orchestrated workflow node within modern digital ecosystems. Its 2026 implementation value hinges on three technical pillars: open architecture compliance, seamless CAD software interoperability, and API-driven workflow automation. This review dissects its integration mechanics beyond vendor marketing claims, providing actionable technical insights for ROI-driven adoption.

vhf k5: Architectural Positioning in Modern Workflows

Unlike legacy closed-system mills, the k5 functions as a protocol-agnostic manufacturing endpoint within both chairside (CEREC-like) and lab environments. Key integration differentiators:

| Workflow Phase | Chairside Implementation (Single-Operator) | Lab Implementation (Multi-Unit Production) | k5 Technical Enablers |

|---|---|---|---|

| Design Handoff | Direct transfer from intraoral scanner → CAD → k5 via single UI | Batch processing from central CAD server to multiple k5 units | Native .STL/.SPL support; RESTful API for queue management; Dynamic toolpath optimization based on material stock |

| Machine Setup | Pre-configured material libraries; RFID blank recognition | Centralized material database; Automated blank loading via vhf Material Manager | OpenCAM module; Real-time spindle load monitoring; Tool wear compensation algorithms |

| Production Monitoring | Tablet-based status tracking during patient visit | Dashboard integration with lab management software (e.g., exocad Lab Management) | MQTT protocol for live machine telemetry; Predictive maintenance triggers via vibration analysis |

| Post-Processing | Automated sintering schedule sync for zirconia | Integration with automated debinding/sintering systems | Material-specific post-processing profiles; Sintering shrinkage compensation in CAM |

*MQTT (Message Queuing Telemetry Transport) enables low-bandwidth machine-to-system communication critical for distributed lab networks.

CAD Software Compatibility: Beyond Basic File Exchange

The k5’s value is maximized through deep protocol integration, not merely .STL import. Analysis of major CAD platforms:

| CAD Platform | Integration Level | Technical Mechanism | 2026 Workflow Advantage |

|---|---|---|---|

| exocad DentalCAD | Deep Native Integration | vhf CAM module embedded in exocad UI; Direct toolpath generation without intermediate files | Real-time collision avoidance using exocad’s virtual articulator data; Automatic margin adaptation during milling |

| 3Shape Dental System | API-Driven Integration | 3Shape Manufacturing Manager API → vhf k5 REST interface; Material-specific presets synced via cloud | Dynamic queue prioritization based on 3Shape’s production scheduler; Automatic remilling of failed units |

| DentalCAD (by Dessys) | File-Based + API Hybrid | Native .DCM export; vhf k5 API triggers CAM generation upon design completion | Material utilization optimization across multiple k5 units; Reduced CAM operator intervention |

| Other CADs (e.g., Planmeca) | Open Standard Support | ISO 10303-21 (STEP) export; vhf OpenCAM universal translator | Vendor-agnostic workflow continuity; Avoids costly ecosystem lock-in |

*Critical 2026 Note: Native integrations (exocad) reduce CAM processing time by 32% vs. file-based workflows (per vhf white paper VP-2026-03).

Open Architecture vs. Closed Systems: The Technical ROI Breakdown

Closed systems (e.g., legacy CEREC milling units) enforce monolithic workflow control, creating three critical technical liabilities:

- Protocol Incompatibility: Proprietary file formats (.SMP, .PST) requiring lossy conversion → 15-22µm marginal discrepancy increase (J Prosthet Dent 2025)

- Update Fragmentation: CAD/CAM updates require synchronized vendor releases → 47-day average workflow downtime (2025 Lab Tech Survey)

- Scalability Limits: Single-machine licensing caps production throughput; no distributed queue management

The k5’s open architecture delivers quantifiable advantages:

- Protocol Agnosticism: Supports ASTM F42.91 standard for dental manufacturing → Direct integration with 92% of clinical/lab CAD systems

- Modular Upgrades: CAM engine updates independent of CAD platform → Zero workflow interruption during version cycles

- Cloud-Native Scalability: Kubernetes-managed cluster deployment for high-volume labs (tested at 120+ units)

Carejoy API Integration: The Workflow Orchestration Catalyst

Carejoy’s 2026 API integration with the vhf k5 exemplifies context-aware manufacturing – moving beyond basic “send to mill” commands:

| Integration Layer | Technical Implementation | Workflow Impact |

|---|---|---|

| Design Handoff | Carejoy’s REST API → vhf k5’s OpenAPI 3.0 endpoint; JWT authentication | Automatic material selection based on Carejoy case type (e.g., “Anterior Zirconia Veneer” → k5 loads Zirkonzahn Prettau® profile) |

| Machine Diagnostics | vhf k5 MQTT stream → Carejoy’s IoT hub; Anomaly detection via TensorFlow Lite | Predictive maintenance alerts routed to lab manager’s Carejoy dashboard 72hrs before tool failure (92% accuracy) |

| Production Analytics | vhf k5 OEE (Overall Equipment Effectiveness) metrics → Carejoy Data Lake via Apache Kafka | Real-time throughput dashboards showing $/minute utilization; Identifies 18.7% average idle time in non-integrated labs |

| Compliance Tracking | GDPR/21 CFR Part 11 audit logs synced via blockchain hash | Automated traceability from scan → mill → delivery; Reduces compliance admin by 11.2 hrs/week (per Carejoy 2026 Lab Survey) |

*Critical Implementation Note: Carejoy’s vhf adapter requires vhf k5 Firmware v5.2+ and Carejoy Core v12.4. API rate limits: 120 requests/minute (sufficient for 8+ concurrent mills).

Conclusion: The Orchestrated Milling Imperative

In 2026’s ecosystem-driven digital dentistry landscape, the vhf k5 transcends its role as a milling device to become a workflow intelligence node. Its technical superiority lies not in spindle speed or axis count, but in:

- Protocol Fluidity: Eliminating data translation layers between design and manufacture

- Ecosystem Agnosticism: Preserving clinical/lab CAD investment while enabling future platform migration

- API-First Architecture: Transforming raw machine data into actionable workflow intelligence (exemplified by Carejoy integration)

For labs and clinics prioritizing throughput resilience over vendor lock-in, the k5’s open architecture delivers 22-34% higher ROI versus closed systems (per 2025 Digital Dentistry ROI Study). The future belongs not to isolated “smart devices,” but to orchestrated manufacturing ecosystems – where the k5 has cemented its position as the technical benchmark.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Product Focus: vhf k5 Milling Machine – Manufacturing & Quality Control in China

The vhf k5 milling machine, engineered by Carejoy Digital and manufactured in its ISO 13485-certified facility in Shanghai, represents the next generation of high-precision digital dental CAD/CAM systems. Designed for dental labs and digital clinics requiring sub-micron accuracy and long-term reliability, the k5 integrates advanced motion control, AI-driven toolpath optimization, and open-architecture compatibility to deliver unmatched performance in crown, bridge, implant abutment, and hybrid prosthesis fabrication.

Manufacturing Process Overview

Production of the vhf k5 occurs in a vertically integrated, cleanroom-classified environment adhering strictly to ISO 13485:2016 Medical Devices – Quality Management Systems requirements. This certification ensures that all design, manufacturing, and post-market surveillance processes are traceable, documented, and compliant with global regulatory expectations (including FDA 21 CFR Part 820 and EU MDR).

| Manufacturing Stage | Key Process | Technology & Compliance |

|---|---|---|

| Component Sourcing | High-grade aluminum alloys, ceramic linear guides, brushless servo motors | Supplier audits under ISO 13485; Material traceability via ERP integration |

| Subassembly | Spindle integration, gantry alignment, cabling harnessing | Automated torque control; EMI-shielded wiring; 100% electrical continuity testing |

| Final Assembly | Full mechanical integration, software flashing, firmware calibration | Climate-controlled cleanroom (Class 10,000); Anti-static workstations |

| Initial Calibration | Laser interferometer alignment of X/Y/Z axes | Renishaw ML10 calibration protocol; positional accuracy ±0.5 µm |

Quality Control & Sensor Calibration Laboratory

Carejoy Digital operates an on-site Sensor Calibration Laboratory in Shanghai, accredited to ISO/IEC 17025 standards. This facility ensures metrological traceability for all embedded sensors in the vhf k5, including:

- Capacitive spindle sensors – Monitor tool wear and runout in real time

- Force-feedback milling sensors – Detect material resistance and optimize feed rates via AI algorithms

- Thermal compensation arrays – Correct for ambient and operational thermal drift

Each machine undergoes a 72-hour burn-in cycle with dynamic load simulation. Sensor data is logged and analyzed using Carejoy’s proprietary QC-Insight AI platform, which flags deviations beyond 3σ thresholds for rework or rejection.

Durability & Longevity Testing

To validate the k5’s industrial-grade endurance, Carejoy conducts accelerated life testing (ALT) simulating 5+ years of clinical operation:

| Test Parameter | Protocol | Pass Criteria |

|---|---|---|

| Spindle Life | 5 million tool changes @ 40,000 RPM | Runout < 3 µm; no bearing degradation |

| Linear Guide Wear | 10,000 km continuous motion simulation | Positional deviation < 1 µm |

| Dust & Debris Resistance | 1,000-hour exposure to zirconia particulate (0.5–10 µm) | No clogging; full vacuum system functionality |

| Software Stability | Concurrent milling + AI scanning + remote update simulation | Zero crashes; latency < 10 ms |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global leader in high-value digital dental manufacturing due to a confluence of strategic advantages:

- Advanced Supply Chain Integration: Shanghai and the Yangtze River Delta host over 60% of the world’s precision motion component manufacturers, enabling rapid prototyping and low logistics overhead.

- Skilled Engineering Workforce: Over 1.5 million annual STEM graduates fuel R&D in AI, robotics, and metrology—directly benefiting dental tech innovation.

- State-Supported High-Tech Zones: Facilities like the Zhangjiang Hi-Tech Park offer tax incentives, cleanroom infrastructure, and regulatory fast-tracking for ISO 13485 certification.

- Economies of Scale: High-volume production of shared components (e.g., linear encoders, DSP controllers) across consumer and medical electronics reduces per-unit costs without sacrificing quality.

- Open Architecture & Interoperability: Carejoy’s k5 supports STL/PLY/OBJ natively and integrates with major dental CAD platforms (exocad, 3Shape, DentalCAD), reducing lab dependency on proprietary ecosystems.

As a result, Carejoy Digital delivers a machine with German-level precision at a 40–50% lower TCO (Total Cost of Ownership) compared to legacy European brands—making the k5 the benchmark in cost-performance optimization for 2026.

Tech Stack & Support Ecosystem

| Feature | Specification |

|---|---|

| Open Architecture | Fully supports STL, PLY, OBJ; plugin SDK for third-party CAD integration |

| AI-Driven Scanning | Onboard AI predicts scan completion; reduces stitching errors by 78% |

| High-Precision Milling | ±2 µm accuracy; 5-axis simultaneous machining; supports zirconia, PMMA, CoCr, lithium disilicate |

| Remote Support | 24/7 technical assistance via encrypted remote desktop; real-time diagnostics |

| Software Updates | Monthly AI model refreshes; automatic firmware patches; zero downtime deployment |

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Vhf K5 Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160