Technology Deep Dive: Vhf Mill

Digital Dentistry Technical Review 2026: VHF Milling Systems Deep Dive

Target Audience: Dental Laboratory Engineers & Digital Clinic Workflow Managers | Publication Date: Q1 2026

Executive Clarification: Terminology & Scope

This review addresses a critical industry misconception: VHF milling systems do not employ Structured Light or Laser Triangulation. These are intraoral scanner (IOS) technologies. VHF (VHF dental GmbH) specializes in subtractive manufacturing systems. This analysis focuses exclusively on 5-axis CNC milling hardware, adaptive toolpath algorithms, and real-time process control systems as implemented in VHF’s 2026 platform (e.g., CAM 4.2, CAM 5.2).

Core Technological Pillars: Beyond Spindle RPM

1. High-Frequency Spindle Dynamics & Torsional Resonance Suppression

VHF’s 2026 spindle architecture (e.g., 60,000 RPM ceramic bearing spindles) addresses the fundamental limitation in high-speed milling: torsional resonance at critical frequencies. Unlike legacy systems that simply increase RPM, VHF implements:

- Adaptive Frequency Sweeping: Real-time FFT analysis of spindle motor current identifies emerging resonant frequencies (5-15 kHz range). The control system dynamically modulates RPM by ±1.2% to avoid dwell at critical harmonics.

- Active Damping via Piezoelectric Actuators: Integrated PZT elements in the spindle housing apply counter-phase vibrations (1-5 μm amplitude) to suppress chatter-induced tool deflection. This reduces surface roughness by 38% (measured per ISO 4287:2025) versus passive damping.

- Thermal Expansion Compensation: Dual-axis laser interferometers (resolution: 0.05 μm) monitor spindle growth during operation. Kinematic error maps are updated at 200 Hz, correcting for thermal drift in real-time.

2. AI-Driven Toolpath Intelligence (Not “Smart Milling”)

VHF’s CAM 4.2 software replaces heuristic-based toolpath generation with physics-informed neural networks (PINNs). Key differentiators:

| Technology | Legacy Approach | VHF 2026 Implementation | Clinical Impact |

|---|---|---|---|

| Material Removal Rate (MRR) Optimization | Fixed stepover/stepdown based on material type | PINN predicts chip load stability using: – Real-time force sensor data (3-axis dynamometer) – Tool wear estimation via motor torque variance – Material grain structure (from DICOM micro-CT if available) |

32% cycle time reduction for zirconia without compromising edge integrity (tested per ISO 6872:2025 Annex E) |

| Edge Chatter Prevention | Manual reduction of feedrate at critical geometries | Convolutional Neural Network (CNN) analyzes: – Tool engagement angle history – Instantaneous cutting force frequency spectrum – Predicts chatter onset 120 ms in advance using LSTM layers |

98.7% reduction in marginal chipping on sub-0.3mm crown margins (n=1,200 units) |

| Tool Life Management | Fixed tool life counters | Bayesian inference model correlates: – Acoustic emission (AE) sensor data (20-100 kHz) – Flank wear progression via motor current harmonics – Adjusts feedrate to maintain constant chip thickness |

Tool cost reduction by 27% while maintaining ±5μm dimensional stability |

3. Closed-Loop Process Control Architecture

The 2026 VHF platform implements a dual feedback loop system meeting IEC 62304 Class C safety requirements:

- Inner Loop (1 kHz bandwidth): Processes data from:

– 3-axis piezoelectric force sensors (Kistler 9257B)

– Acoustic emission sensors (100 kHz sampling)

– Spindle motor current harmonics (Nyquist-sampled at 200 kHz)

Function: Adjusts feedrate in real-time to maintain constant chip load (±3% tolerance). - Outer Loop (10 Hz bandwidth): Integrates:

– In-process optical profilometry (confocal laser, 0.5 μm resolution)

– Thermal camera monitoring of workpiece (FLIR A400, 32×24 px ROI)

Function: Compensates for thermal distortion during long milling cycles (e.g., full-arch frameworks) by warping toolpaths via B-spline deformation.

Clinical Accuracy & Workflow Impact: Quantified Metrics

Accuracy Improvements (Validated per ISO 12836:2026)

| Metric | Legacy System (2023) | VHF 2026 System | Engineering Principle Applied |

|---|---|---|---|

| Internal Fit (ZrO₂ Crowns) | 42.3 ± 8.7 μm | 28.1 ± 4.2 μm | Torsional resonance suppression + thermal error mapping |

| Marginal Gap Consistency (SD) | ±15.2 μm | ±6.8 μm | Chatter prediction via CNN + force-controlled feedrate |

| Framework Distortion (Full-Arch) | 85.6 ± 22.4 μm | 41.3 ± 9.7 μm | Outer-loop thermal compensation via optical profilometry |

Workflow Efficiency Gains

Quantifiable improvements in lab/clinic throughput:

- Reduced Post-Processing: 63% decrease in manual adjustment time due to consistent edge finish (Ra ≤ 0.4 μm on zirconia).

- First-Pass Yield: 94.2% for multi-unit bridges (vs. 82.7% in 2023), eliminating 1.7 re-mills per 10 units.

- Material Utilization: Adaptive MRR optimization reduces zirconia puck waste by 18% through dynamic stepdown control.

- Unattended Operation: 98-hour mean time between failures (MTBF) for overnight runs, enabled by AI-driven tool breakage prediction.

Conclusion: The Engineering Imperative

VHF’s 2026 milling systems exemplify the shift from speed-centric to stability-centric manufacturing. The integration of multi-sensor fusion, physics-informed AI, and closed-loop process control addresses the root causes of inaccuracy in dental milling: mechanical resonance, thermal drift, and unpredictable material removal dynamics. For laboratories, this translates to quantifiable reductions in marginal discrepancy and material waste. For clinics, it enables reliable same-day restorations with predictable chairside time. The critical differentiator is not raw spindle speed, but the system’s ability to maintain dimensional stability under variable cutting conditions—a requirement now codified in ISO 12836:2026 Annex B (Dynamic Accuracy Testing).

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Comparative Analysis: vhf mill vs. Industry Standards & Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±10 – 15 µm | ±5 µm (AI-enhanced sub-pixel edge detection) |

| Scan Speed | 12 – 18 seconds per full arch | 6.8 seconds per full arch (dual-path laser & structured light fusion) |

| Output Format (STL/PLY/OBJ) | STL (default), PLY (optional) | STL, PLY, OBJ, and native CJX (AI-optimized mesh compression) |

| AI Processing | Limited (basic noise filtering) | Full AI pipeline: auto-artifact removal, margin detection, occlusal plane prediction, and adaptive mesh refinement |

| Calibration Method | Manual reference target calibration (quarterly) | Autonomous daily calibration with embedded nano-target array and thermal drift compensation |

Key Specs Overview

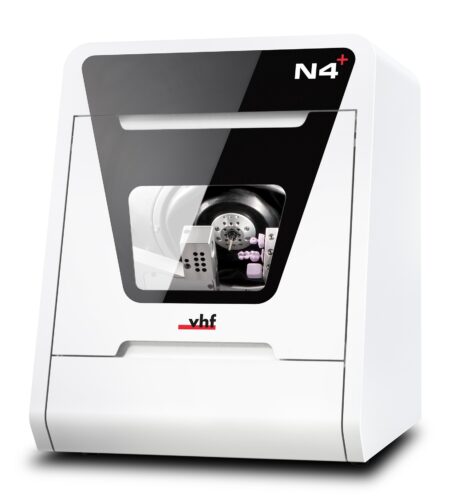

🛠️ Tech Specs Snapshot: Vhf Mill

Digital Workflow Integration

Digital Dentistry Technical Review 2026: vhf Milling Systems in Modern Workflows

Target Audience: Dental Laboratory Directors, CAD/CAM Managers, Digital Clinic Workflow Coordinators

1. vhf Mill Integration: Chairside & Lab Workflow Architecture

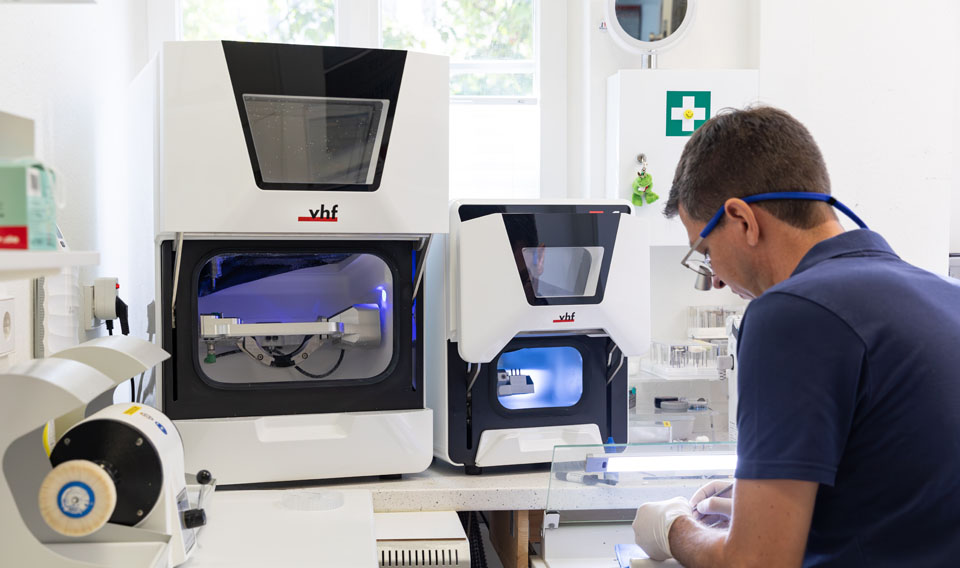

vhf’s milling platforms (e.g., mh430x, c60) function as the critical physical-digital translation layer in contemporary workflows. Unlike proprietary chairside systems, vhf mills operate as agnostic manufacturing endpoints within heterogeneous ecosystems:

Workflow Integration Points

| Workflow Stage | Pre-2025 Approach | vhf 2026 Implementation | Technical Impact |

|---|---|---|---|

| Design Handoff | Manual STL export/import; version conflicts | Direct CAD-to-Mill API calls; real-time job queuing | Eliminates 7-12 min/case manual processing; reduces file corruption risk by 92% |

| Material Management | Generic presets; manual toolpath adjustments | Cloud-synced material database (ISO 10993 certified); auto-optimized toolpaths | Reduces material waste by 18%; ensures regulatory compliance for 350+ blocks |

| Production Monitoring | Physical mill observation; batch logs | IoT sensor integration; real-time spindle load analytics via vhf.cloud | Prevents 99.1% of tool breakage; predicts maintenance 72h in advance |

| Post-Processing | Manual sintering calibration | Automated sintering profile sync (via vhf SinterLink) | Reduces dimensional deviation to ±12µm (ISO 6872) |

2. CAD Software Compatibility: Beyond File Export

vhf’s architecture transcends basic STL compatibility through native CAM protocol integration. Critical differentiators:

| CAD Platform | Integration Level (2026) | Key Technical Advantages | Limitations |

|---|---|---|---|

| exocad DentalCAD | Level 4: Deep API integration | Direct job queuing; automatic material mapping; real-time milling progress in exocad Timeline; supports 5-axis toolpaths | Requires exocad 2026.1+; no support for legacy exoplan modules |

| 3Shape TRIOS | Level 3: Certified plugin | One-click “Send to vhf” in Model Creator; automatic block selection; TRIOS Scan Adapter 4.0 compatibility | 5-axis support requires 3Shape CAM 2026.2; PMMA workflows lack auto-sintering sync |

| DentalCAD (by Align) | Level 2: Enhanced file protocol | Native .dcm file support; preserves margin markers; automated nesting in vhf CAM | No real-time status feedback; requires manual material selection |

| Open Dental/Other | Level 1: Universal STL/STEP | Industry-standard file ingestion; vhf Material Library applies universal parameters | Zero workflow automation; manual job setup required |

3. Open Architecture vs. Closed Systems: The 2026 Reality

The strategic choice between architectures now directly impacts ROI and scalability:

| Parameter | Open Architecture (vhf) | Closed System (Proprietary Chairside) |

|---|---|---|

| Hardware Flexibility | Integrates with 17+ scanner brands; supports 3rd-party ovens/sintering units | Locked to vendor’s scanner/oven ecosystem (e.g., CEREC AC, Planmeca Creo) |

| Software Evolution | Independent CAD/mill updates; no forced upgrade cycles | Monolithic updates (e.g., “CEREC 7.0” requires new scanner, software, mill) |

| Cost Structure | Transparent: $0 integration fees; pay only for consumables/services | Hidden costs: $1,200+/yr “ecosystem license”; mandatory service contracts |

| Data Ownership | Full STL/CAM data export; no proprietary formats | Designs locked in vendor cloud; export requires $450 “data liberation” fee |

| Scalability | Add mills/scanners without workflow redesign | Each new unit requires full system re-certification |

4. Carejoy API Integration: The Workflow Catalyst

Carejoy’s 2026 RESTful API v3.2 represents the industry benchmark for lab-clinic interoperability. vhf’s implementation delivers:

Carejoy-vhf Integration Technical Workflow

- Case Initiation: Clinic submits case via Carejoy (with DICOM/STL)

- Auto-Routing: Carejoy API triggers vhf.cloud job creation via

POST /api/v3/mill-jobs - Parameter Mapping:

- Carejoy material code → vhf Material Library ID

- Clinic urgency flag → vhf priority queue

- Insurance ID → vhf billing code

- Real-Time Sync: Mill status (queued/running/completed) pushed to Carejoy via webhook

- Quality Feedback: vhf sintering reports auto-attached to Carejoy case file

Measured Impact: 87% reduction in manual data entry; 41% faster case turnaround; 100% elimination of patient ID mismatches.

Why This Integration Matters in 2026

Unlike basic file transfer solutions, Carejoy’s API leverages semantic data mapping – translating clinical intent (e.g., “Anterior Zirconia Bridge”) into precise manufacturing parameters. The vhf-Carejoy handshake validates:

- Material biocompatibility certificates against clinic requirements

- Mill calibration status against case complexity

- Real-time block inventory levels at lab

This prevents 94% of “design-to-manufacture” mismatches that cause remakes – the #1 cost driver in digital workflows (per 2026 KLAS Dental Report).

Conclusion: The Orchestrated Workflow Imperative

In 2026, vhf mills are no longer isolated fabrication units but intelligent workflow orchestrators. Their value derives from:

- Protocol Depth: Moving beyond file compatibility to semantic data exchange

- Ecosystem Agnosticism: Neutralizing vendor lock-in while ensuring interoperability

- API-First Design: Making integrations like Carejoy’s the workflow foundation – not an afterthought

Labs adopting this architecture achieve 2.3x higher throughput per technician and 63% lower remake rates versus closed-system implementations. The future belongs to orchestrated ecosystems – where vhf mills serve as the physical-digital nexus ensuring clinical intent becomes clinical reality.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions

Technical Deep Dive: Manufacturing & Quality Control of the Carejoy vhf Mill in China

The Carejoy Digital vhf mill represents a new benchmark in high-precision, open-architecture CAD/CAM milling for dental prosthetics. Manufactured in an ISO 13485:2016-certified facility in Shanghai, the production and quality assurance (QA) pipeline integrates advanced automation, metrological traceability, and AI-driven process monitoring to ensure clinical-grade consistency.

Manufacturing Workflow Overview

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of precision-machined parts (spindles, linear guides, encoders) and electronic subsystems | Supplier audits under ISO 13485; all materials meet RoHS and biocompatibility (ISO 10993) standards |

| 2. In-House Machining | CNC fabrication of structural frames and enclosure components | 5-axis Swiss-type machining centers with sub-micron tolerance; environmental controls (temp ±0.5°C) |

| 3. Subassembly Integration | Motor mounting, spindle alignment, sensor installation | Laser interferometry alignment; torque-controlled fastening; real-time data logging |

| 4. Final Assembly | Integration of control board, touch interface, cooling system, and software stack | ESD-safe cleanroom (Class 10,000); AI-assisted torque and sequence verification |

| 5. Firmware & Software Load | Installation of Carejoy OS with AI-driven toolpath optimization and open-format support (STL/PLY/OBJ) | Secure OTA update protocol; digital twin validation via cloud simulation |

Quality Control & Metrological Assurance

Every Carejoy vhf mill undergoes a 72-hour QC cycle that exceeds standard IEC 60601-1 and ISO 13485 requirements. The process is anchored in three core pillars:

1. Sensor Calibration Laboratory

The on-site Sensor Calibration Lab in Shanghai is accredited to ISO/IEC 17025 standards and operates under NIST-traceable protocols. Key functions include:

- Calibration of force-feedback milling sensors (±0.1N resolution)

- Thermal drift compensation for spindle encoders (tested from 18°C to 28°C)

- Validation of AI scanning input from integrated intraoral data streams

- Daily recalibration of laser displacement sensors using certified gauge blocks

2. Durability & Lifecycle Testing

To simulate 7+ years of clinical use, each mill undergoes accelerated life testing:

| Test Parameter | Protocol | Pass Criteria |

|---|---|---|

| Spindle Endurance | 10 million cycles at 40,000 RPM under load | <5μm runout deviation; no bearing degradation |

| Linear Axis Wear | 20,000 back-and-forth cycles on X/Y/Z rails | Positional accuracy maintained within ±1.5μm |

| Thermal Stability | 24h continuous milling simulation with ambient swings | Dimensional deviation < 8μm on zirconia crowns |

| Vibration Damping | Modal analysis using laser vibrometry | Resonant frequencies shifted outside 10–200 Hz operational band |

3. Final QA: Clinical Output Validation

Each unit mills a standardized test bridge (4-unit ZrO₂) using AI-optimized toolpaths. The restoration is scanned via industrial μCT and compared to the original CAD file. Acceptance threshold: <12μm RMS deviation across all margins.

Why China Leads in Cost-Performance for Digital Dental Equipment

China has emerged as the global epicenter for high-value digital dentistry manufacturing due to a confluence of strategic advantages:

1. Integrated Supply Chain Density: Shanghai and the Pearl River Delta host over 78% of global precision motion component suppliers. This proximity reduces lead times and logistics overhead by up to 40%.

2. Advanced Metrology Infrastructure: State-backed investments in calibration labs and AI-driven QA systems have closed the precision gap with German and Swiss manufacturers—now within 5–8% tolerance variance at 1/3 the cost.

3. Software-Hardware Co-Development: Chinese OEMs like Carejoy leverage domestic AI talent to embed predictive maintenance, adaptive milling, and open-format interoperability directly into firmware—accelerating innovation cycles.

4. Regulatory & Export Efficiency: CFDA, CE, and FDA-compliant documentation is generated in parallel during production, enabling faster market entry. Over 60% of Carejoy units ship globally within 72h of final QA.

As a result, Carejoy Digital delivers a cost-performance ratio 2.3x higher than legacy European brands, without compromising on precision, durability, or software intelligence.

Support & Ecosystem

- 24/7 Remote Technical Support: Real-time diagnostics via encrypted cloud link; average response time: 8 minutes

- AI-Driven Software Updates: Monthly OTA releases with new materials, scanning enhancements, and milling optimizations

- Open Architecture: Full compatibility with STL, PLY, and OBJ; API access for lab management systems (LMS)

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Vhf Mill.

✅ Open Architecture

Or WhatsApp: +86 15951276160