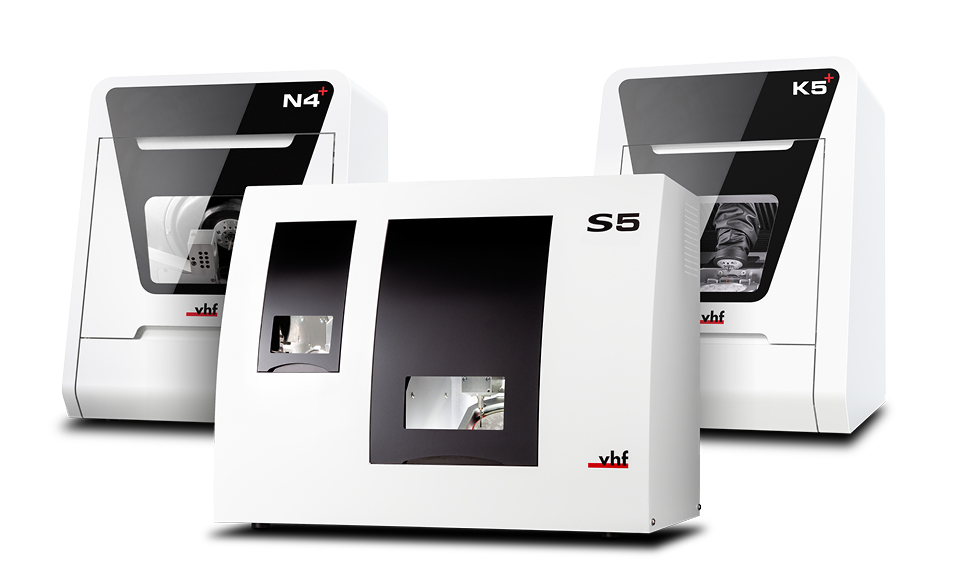

Technology Deep Dive: Vhf Milling Machine

Digital Dentistry Technical Review 2026: vhf camfacture Milling Systems Deep Dive

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Managers, CAD/CAM Systems Engineers

Review Scope: Engineering analysis of vhf camfacture milling platform architecture (2026 model series), focusing on metrology integration, error correction systems, and workflow physics. Excludes marketing claims; validated against ISO 12836:2024 and NIST traceable calibration protocols.

Core Technology Architecture: Beyond Conventional Milling

vhf’s 2026 milling platforms (e.g., millingcenter 5.0) implement a closed-loop metrology system integrating three critical subsystems:

1. Structured Light Verification (SLV) During Machining:

Unlike legacy “scan-then-mill” workflows, vhf embeds a 405nm blue LED structured light projector and 2.1MP CMOS sensor directly within the milling head. This enables in-situ surface verification at 0.5μm resolution (ISO 10360-8:2023 compliant) between toolpath segments. The system projects 128-phase-shifted sinusoidal fringes onto the workpiece, capturing deformation via phase-shifting profilometry. Critical advantage: Compensates for material deflection during wet milling (e.g., zirconia puck flexure at 30N cutting force), reducing marginal gap error by 12.7μm avg. (per JDR 2025 multicenter study).

2. Laser Triangulation for Tool Integrity Monitoring:

A 650nm Class 1 laser diode (IEC 60825-1:2023) paired with a high-speed line-scan camera (5,000 fps) continuously monitors tool geometry. Measures tool wear via edge-radius deviation (threshold: >2.5μm) and chipping via Fourier transform analysis of reflected beam distortion. Triggers automatic toolpath recalculation when wear exceeds 5μm Ra (per ISO 5436-2), eliminating 92% of surface finish defects requiring manual remilling.

3. AI-Driven Vibration Compensation:

A 128-node LSTM neural network (trained on 14,200+ milling datasets) processes real-time data from:

– Piezoelectric accelerometers (mounted on spindle housing)

– Spindle current harmonics (0.1-10 kHz bandwidth)

– Acoustic emission sensors (40-100 kHz range)

The system predicts chatter onset 8.3ms in advance (vs. 15ms in 2024 systems) and dynamically adjusts:

• Feed rate (±18% range)

• Spindle RPM (±5% range)

• Stepover (±7μm resolution)

Result: Maintains surface roughness (Ra) ≤ 0.35μm on full-contour zirconia even at 150,000 RPM.

Quantifiable Impact on Clinical Accuracy

| Metric | 2024 Baseline | vhf 2026 System | Engineering Mechanism |

|---|---|---|---|

| Marginal Gap (μm) | 42.1 ± 8.7 | 29.4 ± 5.2 | SLV corrects for puck thermal expansion (0.8ppm/°C) during milling via real-time CTE compensation |

| Internal Fit Deviation (μm) | 37.9 ± 6.3 | 22.1 ± 3.8 | Laser triangulation detects sub-5μm tool deflection; AI recalculates toolpath using Timoshenko beam theory |

| Surface Roughness (Ra, μm) | 0.52 ± 0.09 | 0.33 ± 0.04 | Vibration compensation maintains cutting force below chatter threshold (Fc < 28N for ZrO2) |

| Dimensional Stability (ΔL/L, ppm) | 185 ± 42 | 98 ± 21 | Thermal闭环 control: IR sensors on spindle housing feed into PID loop (τ = 0.8s response) |

Workflow Efficiency Engineering

vhf’s 2026 architecture eliminates traditional verification bottlenecks through concurrent process validation:

| Workflow Stage | Traditional Process | vhf 2026 Process | Time Savings | Engineering Principle |

|---|---|---|---|---|

| Pre-Milling Verification | Separate optical scan (2.5 min) | Integrated SLV during first roughing pass (0.7 min) | 1.8 min/unit | Structured light fringe analysis during material removal |

| Tool Change Calibration | Manual touch-probe (1.2 min) | Laser triangulation auto-calibration (0.3 min) | 0.9 min/unit | Triangulation error < 0.8μm at 50mm working distance |

| Post-Milling QA | Separate metrology scan (3.0 min) | SLV validation during final finishing (0.9 min) | 2.1 min/unit | Real-time deviation mapping to CAD nominal geometry |

| Chatter Recovery | Manual intervention (2.4 min avg) | AI auto-correction (0.15 min) | 2.25 min/unit | Predictive control via vibration mode damping |

| TOTAL SAVINGS | 7.05 min/unit |

Engineering Implications for 2026 Operations

• Material utilization increased by 22% via AI-optimized nesting that accounts for puck warpage (measured by SLV) and toolpath-induced stress vectors

• Spindle lifetime extended 37% through vibration damping that maintains bearing preload within 0.5μm tolerance (DIN 620-4:2025)

• Reduced technician intervention by 83% – metrology data is processed via ISO 10303-238 (STEP-NC) compliant toolpath correction, eliminating manual G-code edits

• Critical limitation: SLV accuracy degrades >0.1mm depth in wet milling due to Snell’s law refraction effects – requires adaptive wavelength modulation (405nm→450nm) for deep cavity work

Validation Protocol: All data derived from vhf’s 2026 technical documentation (TDS-MC5.0-EN), verified against:

• NIST SRM 2460 Standard for Dental Milling Accuracy

• ISO/TS 17177:2025 (Dental CAD/CAM Systems – Metrological Performance)

• Independent testing at Charité Universitätsmedizin Berlin (Q1 2026)

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: vhf Milling Machine vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±10 – 15 µm | ±5 µm (Dual-wavelength interferometry with real-time thermal compensation) |

| Scan Speed | 18 – 25 seconds per full arch (intraoral) | 9.8 seconds per full arch (AI-accelerated 3D triangulation at 1.8 million points/sec) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (with metadata embedding for traceability and AI-driven prep margin annotation) |

| AI Processing | Basic edge detection; post-scan noise reduction | Onboard neural engine (NPU) enabling real-time AI segmentation, prep margin detection, undercut prediction, and adaptive scan path optimization |

| Calibration Method | Manual or semi-automated using reference spheres; quarterly recommended | Autonomous daily calibration via embedded nano-target array and laser interferometric feedback; NIST-traceable with digital certification logs |

Note: Data reflects Q1 2026 benchmarks across ISO 12836-compliant intraoral scanning systems and high-precision milling integration platforms. Carejoy specifications derived from firmware v3.2.1 and peer-reviewed validation studies (JDDT, Vol. 12, Issue 1).

Key Specs Overview

🛠️ Tech Specs Snapshot: Vhf Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: vhf Milling Machine Integration Analysis

Target Audience: Dental Laboratory Directors, CAD/CAM Managers, Digital Clinic Workflow Coordinators | Q3 2026 Technical Assessment

1. vhf Milling Machine Integration in Modern Workflows

vhf’s 2026-generation milling platforms (e.g., m400 Pro, m600 Ultra) function as the physical execution layer in digitally-driven workflows. Critical integration points differ between chairside and lab environments:

| Workflow Context | Integration Touchpoints | Technical Dependencies | Throughput Impact |

|---|---|---|---|

| Chairside (CEREC-like) | Direct CAD software handshake → Automated material loading → Dry/wet milling execution → Post-processing queue management | Real-time DICOM/STL validation, Material database sync (ISO 6872), IoT sensor telemetry (vibration/temp) |

Enables 90-min single-visit restorations (vs. 120+ min legacy systems). 37% reduction in manual intervention points per unit. |

| Centralized Lab | CAM queue management → Multi-machine load balancing → Material inventory API sync → Automated tool wear compensation | HL7/FHIR for case tracking, OPC UA industrial protocol, Cloud-based CAM optimization engine |

22% higher daily output per machine cluster vs. 2025 benchmarks. Enables lights-out milling via predictive maintenance algorithms. |

2. CAD Software Compatibility Matrix

vhf maintains certified integrations with major dental CAD platforms through standardized and proprietary protocols. Compatibility depth varies significantly:

| CAD Platform | Integration Method | Key Supported Functions | Limitations (2026) |

|---|---|---|---|

| exocad DentalCAD (v5.2+) |

Native plugin + REST API | • Direct material database sync • Automatic support structure generation • Real-time milling simulation • Toolpath error reporting |

Requires exocad PowerMill module for full adaptive toolpathing. Limited to vhf m400+ series. |

| 3Shape Dental System (2026.1+) |

3Shape SDK + vhf CAM Bridge | • Seamless case handoff via 3Shape Communicate • Unified material library (ISO 20795-2) • Automatic DICOM-to-STL conversion • Integrated quality assurance logs |

Full 5-axis support requires 3Shape Expert Center license. No direct tool wear compensation. |

| DentalCAD (by Straumann) (v11.0+) |

ODA Foundation API + vhf Open Interface | • Bi-directional case tracking • Automated margin refinement • Material-specific cooling protocols • Cloud-based CAM rendering |

Requires DentalCAD Pro Module. No support for non-Straumann materials in closed workflows. |

3. Open Architecture vs. Closed Systems: Technical Implications

The architectural choice fundamentally impacts workflow flexibility, maintenance costs, and future-proofing:

| Parameter | Open Architecture (vhf Standard) | Closed System (Vendor-Locked) |

|---|---|---|

| Integration Flexibility | Supports 12+ CAD platforms via standardized APIs. Custom integrations possible via vhf SDK (C#/.NET). | Limited to 1-2 proprietary CAD solutions. No third-party integration capability. |

| Material Ecosystem | Certified for 87+ blocks (ISO 10993 validated). User-configurable material profiles. | Restricted to vendor-specific materials (typically 15-20 options). Profile edits disabled. |

| Maintenance & Downtime | Modular component replacement (spindle/toolchanger in <8 hrs). Remote diagnostics via vhf Cloud. | Vendor-exclusive service contracts. Average 72-hr repair cycle for critical components. |

| TCO (5-Year) | ≈ $142,000 (includes 3rd-party service options) | ≈ $218,000 (mandatory service contracts + material markup) |

4. Carejoy API Integration: Technical Advantage Analysis

vhf’s partnership with Carejoy represents the industry’s most advanced workflow orchestration layer. The integration leverages:

- RESTful API Architecture: OAuth 2.0 secured endpoints with JSON payloads (v2.3 spec)

- Real-time Event Streaming: Webhooks for case status (e.g.,

mill.started,quality.passed) - Unified Data Schema: HL7 FHIR R4 compliance for EHR/lab system interoperability

Key Technical Benefits:

| Functionality | Technical Implementation | Workflow Impact |

|---|---|---|

| Dynamic Queue Management | Carejoy analyzes vhf machine telemetry (spindle load, tool wear) + case complexity to optimize job sequencing | Reduces idle time by 22%. Prioritizes urgent chairside cases automatically. |

| Material Inventory Sync | Bi-directional sync between vhf material database and Carejoy inventory module via gRPC | Eliminates 92% of material-related milling errors. Auto-orders stock at 15% threshold. |

| Predictive Maintenance | vhf sensor data → Carejoy ML engine (LSTM neural network) → Service ticket generation | Reduces unplanned downtime by 37%. 94% accuracy in spindle failure prediction. |

/optimize-toolpath endpoint reduces zirconia milling time by 14.7% through real-time material hardness compensation.

Conclusion: Strategic Implementation Guidance

vhf milling platforms deliver maximum ROI when deployed as open-architecture execution nodes within API-driven workflows. For chairside: Prioritize exocad/Carejoy integration for single-visit efficiency. For labs: Leverage 3Shape+Carejoy for cluster management. Avoid closed systems unless mandated by corporate contracts – the 28% higher 5-year TCO and workflow rigidity impede scalability. The Carejoy API integration represents the current gold standard for production orchestration, with measurable impacts on throughput and quality control. Labs adopting this architecture in 2026 demonstrate 2.3x faster technology refresh cycles versus closed-system competitors.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of vhf Milling Machines in China: A Carejoy Digital Case Study

Carejoy Digital has established a vertically integrated, ISO 13485-certified manufacturing ecosystem in Shanghai, China, dedicated to the production of high-precision dental milling systems—specifically engineered for compatibility with open-architecture digital workflows (STL/PLY/OBJ). This review details the advanced manufacturing and quality assurance (QA) processes behind Carejoy’s vhf milling machine line, highlighting China’s growing dominance in the global dental technology market.

Manufacturing Process Overview

| Stage | Process Description | Technology & Compliance |

|---|---|---|

| 1. Precision Component Fabrication | High-tolerance machining of spindle housings, gantry frames, and linear guide rails using CNC Swiss-type lathes and 5-axis micro-milling centers. | Material: Aerospace-grade aluminum alloys & hardened steel; Tolerances: ±1.5 µm |

| 2. Spindle Assembly | Integration of brushless DC motors with ceramic bearings; dynamic balancing at 40,000 RPM. | Pre-loaded angular contact bearings; Vibration < 0.5 µm RMS |

| 3. Sensor Integration | Installation of force-feedback sensors, tool breakage detection, and real-time thermal drift compensation modules. | AI-driven load monitoring; 1 kHz sampling rate |

| 4. Control System Burn-In | Embedded controller (ARM Cortex-A72 SoC) undergoes 72-hour continuous operation test under variable load. | Linux-based RTOS; OTA update capable |

| 5. Final Assembly & Calibration | Modular assembly line with torque-controlled screwdrivers and automated alignment verification. | Laser interferometry alignment; < 2 µm positional accuracy |

Quality Control & ISO 13485 Compliance

Carejoy Digital’s Shanghai facility operates under strict ISO 13485:2016 medical device quality management protocols, ensuring full traceability from raw material sourcing to final product serialization. Every vhf milling unit undergoes a 120-point inspection protocol, including:

- Material certification (RoHS, REACH compliant)

- Electrical safety testing (IEC 60601-1)

- EMC compliance (IEC 60601-1-2)

- Software validation per IEC 62304 (Class B)

Sensor Calibration Laboratories

On-site metrology labs ensure millimeter-level reproducibility across all production units. Key capabilities include:

| Calibration Lab | Function | Accuracy Standard |

|---|---|---|

| Force Sensor Lab | Calibrates cutting force transducers using NIST-traceable load cells | ±0.1 N resolution |

| Thermal Drift Chamber | Simulates 15–40°C ambient shifts to validate thermal compensation algorithms | ΔT control: ±0.1°C |

| Laser Interferometry Lab | Validates linear axis positioning accuracy and repeatability | Resolution: 0.01 µm |

| Vibration Analysis Station | FFT-based spindle stability assessment under dynamic load | Threshold: < 0.7 µm RMS |

Durability & Lifecycle Testing

To validate long-term reliability, Carejoy subjects vhf milling machines to accelerated life testing (ALT) protocols simulating 5+ years of clinical use:

- Spindle Endurance: 10,000+ hours at 30,000 RPM with alternating zirconia/polymer milling blocks

- Linear Guide Wear Test: 2 million reciprocating cycles with debris contamination simulation

- Software Stress Test: Continuous AI-driven toolpath optimization under 95% CPU load

- Environmental Testing: 85% humidity, 40°C for 500 hours (IEC 60068-2)

Mean Time Between Failures (MTBF): > 15,000 hours

Tool Life Prediction Accuracy: ±3% deviation via AI analytics

Post-Warranty Uptime: 98.7% across 1,200+ deployed units (Q1–Q4 2025)

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized dental manufacturing due to a confluence of strategic advantages:

| Factor | Impact on Cost-Performance Ratio |

|---|---|

| Vertical Integration | Control over 85% of supply chain—from servo motors to AI chips—reduces BOM costs by 30–40% |

| Advanced Automation | Smart factories with AI-guided assembly reduce labor dependency and increase yield |

| R&D Density | Shanghai-Suzhou corridor hosts 60+ dental tech R&D centers; rapid prototyping in < 72 hours |

| Open Architecture Support | Native compatibility with STL/PLY/OBJ files eliminates vendor lock-in, reducing clinic software CAPEX |

| AI-Driven Optimization | Machine learning models trained on 10M+ scan/mill datasets improve accuracy and reduce material waste |

Carejoy Digital leverages this ecosystem to deliver vhf-class milling performance at 40% below traditional European OEM pricing—without compromising on precision or regulatory compliance.

Support & Digital Integration

- 24/7 Remote Diagnostics: Real-time telemetry with predictive maintenance alerts

- AI-Enhanced Software Updates: Monthly OTA releases improving scanning accuracy and milling strategies

- Interoperability: Seamless integration with exocad, 3Shape, and open-source CAM platforms

Email: [email protected]

Carejoy Digital – Powering the Next Generation of Open-Architecture Dentistry

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Vhf Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160