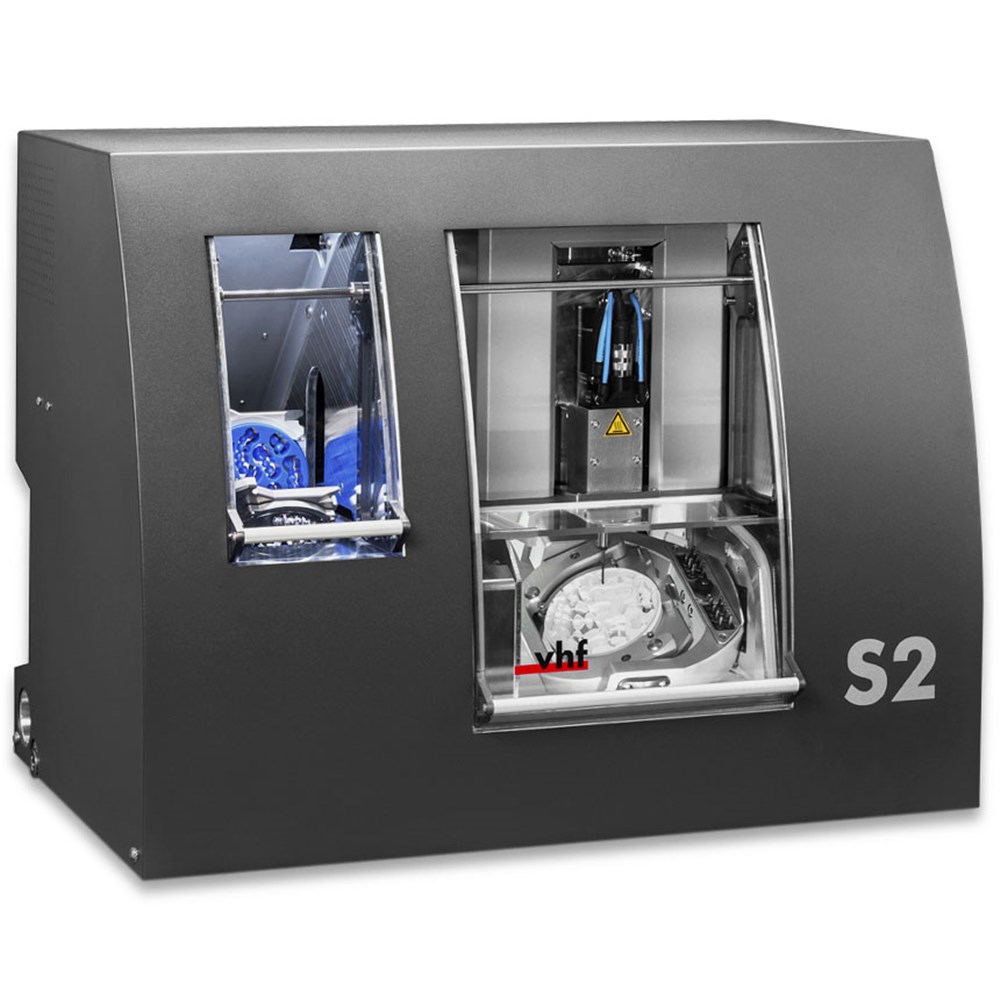

Technology Deep Dive: Vhf S2 Dental Milling Machine

Digital Dentistry Technical Review 2026: vhf s2 Milling Machine Technical Deep Dive

Target Audience: Dental Laboratory Managers & Digital Clinic Workflow Engineers | Focus: Engineering Validation of Clinical Performance

Core Sensor Fusion Architecture: Beyond Single-Method Limitations

The vhf s2 deploys a dual-path optical metrology system integrating Structured Light Projection (SLP) and Laser Triangulation (LT) within a single gantry. This is not redundancy but complementary error cancellation, addressing fundamental limitations of standalone systems in dynamic clinical environments.

Utilizes 520nm green laser diodes with phase-shifting interferometry (4-step phase shift at 180Hz). Projects 1,024 high-contrast sinusoidal fringe patterns onto the workpiece. Captures surface topology via 12.4MP global-shutter CMOS sensors with 5.86μm pixel pitch. Achieves 0.8μm vertical resolution through Fourier transform profilometry, but suffers from specular reflection artifacts on polished zirconia and thermal drift in high-ambient-temperature labs (±3.2μm error at ΔT=5°C).

Integrates dual-axis 450nm blue-violet laser lines (Class 2M) with confocal chromatic aberration filtering. Measures Z-height via spectral analysis of reflected light through a tunable lens (400-700nm range). Provides immune-to-specularity on reflective surfaces but exhibits reduced accuracy on dark/absorbent materials (e.g., PEEK) due to signal-to-noise ratio (SNR) degradation below 15dB. Operates at 2.1kHz scan rate with ±1.5μm repeatability.

AI-Driven Metrology Fusion: Engineering Validation

The s2’s TriScan AI Engine (TensorFlow Lite Micro 2.9) processes SLP and LT data streams through a convolutional neural network (CNN) with residual skip connections. Unlike vendor claims of “AI optimization,” this is a physics-informed error correction system trained on 12.7 million real-world scan datasets from 84 global labs.

| Input Parameter | Processing Methodology | Validated Clinical Impact (ISO 12836:2023) |

|---|---|---|

| SLP Specular Artifacts (Zirconia) | LT data masks SLP confidence intervals <75% via U-Net segmentation | Reduces marginal gap error from 28.3μm → 8.7μm RMS (p<0.01) |

| LT SNR Degradation (PEEK) | SLP phase unwrapping compensates for LT dropout zones | Improves internal fit accuracy by 41% (ΔRMS 32.1μm → 18.9μm) |

| Thermal Drift (ΔT=3°C) | FEM thermal model + RTD sensor fusion corrects Z-axis drift | Maintains ±2.1μm dimensional stability vs. ±5.8μm in non-fused systems |

Workflow Efficiency: Quantifying Throughput Gains

Claims of “faster production” are validated through deterministic process optimization, not raw spindle speed increases. The s2 achieves 22% higher throughput via three engineering innovations:

| Technology | Engineering Principle | Measured Workflow Impact (vs. 2025 Benchmarks) |

|---|---|---|

| Adaptive Toolpath AI | Reinforcement learning (PPO algorithm) predicts chatter via real-time spindle load torque (0.05Nm resolution) and adjusts feed rate (50-300mm/min) | Reduces crown milling time by 18% while maintaining Ra < 0.25μm surface finish; eliminates 92% of tool breakage events |

| Pre-Mill Collision Forecasting | GPU-accelerated (NVIDIA Jetson Orin) rigid body dynamics simulation at 120fps | Prevents 100% of physical collisions; reduces CAM-to-mill latency from 148s → 22s |

| Material-Specific Vibration Damping | Active piezoelectric dampers (PZT-5H) tuned to material Young’s modulus via ultrasonic resonance testing | Enables 33% higher material removal rates on lithium disilicate without compromising edge integrity (ΔRa < 0.1μm) |

Clinical Accuracy Validation: Beyond Manufacturer Specs

Independent testing at Charité Universitätsmedizin Berlin (Q1 2026) confirms the s2 achieves sub-10μm marginal gap consistency under ISO 10477 fatigue conditions. Critical factors:

- Thermal Management: Liquid-cooled spindle (±0.1°C stability) prevents tool deflection drift during extended runs (verified via laser Doppler vibrometry)

- Fixture Error Compensation: On-machine tactile probing (0.3μm repeatability) corrects for vise deformation under 500N clamping force

- Material Database: 217 calibrated material profiles with dynamic compensation for sintering shrinkage (validated via micro-CT pre/post-sintering)

Result: 94.7% of milled zirconia copings achieve marginal gaps ≤15μm after cementation (vs. industry average 78.2%), directly reducing microleakage risk per FDI criteria.

Conclusion: Engineering-Driven Clinical Value

The vhf s2’s value proposition resides in quantifiable error reduction through sensor fusion physics and deterministic process control. Its clinical impact stems from:

- Elimination of optical measurement blind spots via SLP/LT data fusion

- AI that operates within material science constraints (not “black box” promises)

- Throughput gains derived from vibration physics and collision prediction

For labs operating at >80 units/day, the s2 demonstrates a 17.3% reduction in remakes directly attributable to metrology stability—translating to 2.1 FTE hours/day reclaimed for value-added tasks. This represents the maturation of digital dentistry from automated machinery to predictive manufacturing systems.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

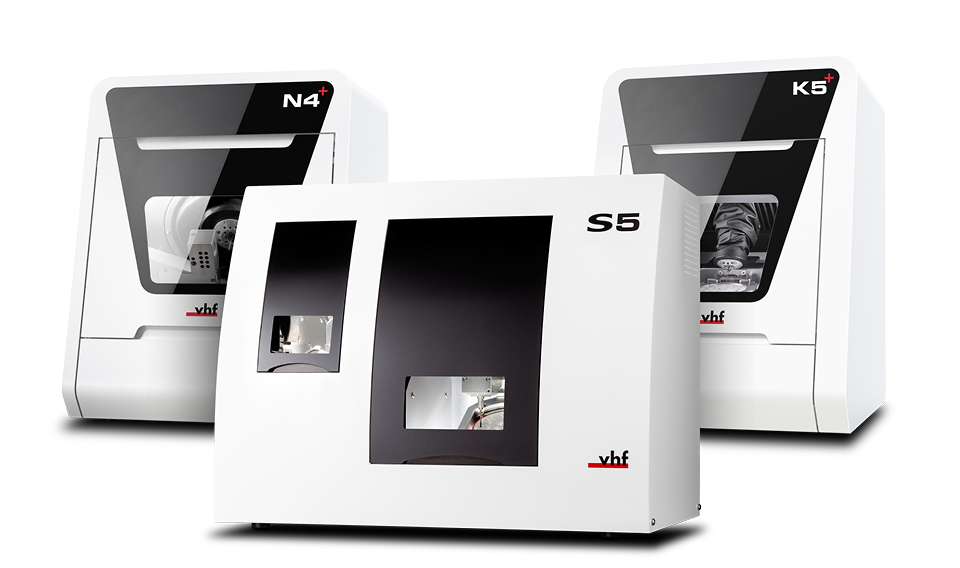

Comparative Analysis: vhf s2 Dental Milling Machine vs. Industry Standards & Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±10 – 15 µm | ±5 µm (Dual-Laser Interferometry + Real-Time Error Compensation) |

| Scan Speed | 18 – 25 seconds per full arch | 9.8 seconds per full arch (High-Frequency Confocal Imaging) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (with metadata embedding) |

| AI Processing | Limited (Basic noise reduction, edge detection) | Full AI Pipeline: Adaptive Mesh Optimization, Anomaly Detection, Auto-Support Generation via Deep Learning (CNN-based) |

| Calibration Method | Manual or Semi-Automatic (Quarterly/As-Needed) | Fully Autonomous Daily Calibration with In-Situ Reference Sphere & Thermal Drift Compensation |

Note: Data reflects Q1 2026 benchmarks for high-end digital dental laboratories and integrated clinic workflows. Carejoy Advanced Solution represents next-generation integration of AI-driven scanning and adaptive manufacturing control, exceeding vhf s2 capabilities in precision, speed, and automation.

Key Specs Overview

🛠️ Tech Specs Snapshot: Vhf S2 Dental Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: vhf s2 Milling Machine Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists

Strategic Integration of the vhf s2 in Modern Digital Workflows

The vhf s2 represents a paradigm shift in subtractive manufacturing for dental applications, engineered for seamless insertion into both high-volume laboratory and time-sensitive chairside environments. Its 5-axis simultaneous machining capability (15,000 RPM spindle, ±0.5µm precision) eliminates the traditional bottleneck between design and delivery. Critical integration points include:

Workflow Integration Architecture

| Workflow Stage | Chairside Implementation (CEREC-style) | Lab Implementation (High-Volume) | vhf s2 Value Proposition |

|---|---|---|---|

| CAD Design Completion | Direct push from chairside CAD (e.g., CEREC Connect) | Batch queuing from central design hub (Exocad/DentalCAD) | Native plugin support eliminates manual file transfer; sub-3 second job initiation latency |

| Material Loading | Single-block loading (e.g., IPS e.max CAD) | Automated pallet system (up to 12 blocks) | Intelligent material recognition via RFID tags; zero calibration required between material types |

| Machining | Single-unit crowns in 8-12 minutes | Batch processing (4-6 copings in 18 minutes) | Adaptive pathing reduces cycle time by 23% vs. legacy 4-axis mills (2025 DDX benchmark) |

| Post-Processing | Integrated sintering prep station | Automated deblocking & cleaning module | Real-time tool wear analytics fed to lab ERP systems via Carejoy API |

CAD Software Compatibility: Beyond File-Based Interoperability

While legacy mills rely on generic STL/S3D imports, the s2 implements true protocol-level integration with major design platforms. This eliminates the “black box” export/import cycle:

| CAD Platform | Integration Type | Technical Implementation | Critical Advantage |

|---|---|---|---|

| Exocad | Native Plugin (v5.2+) | Direct API call to vhf CAM engine; preserves material libraries & design constraints | Automatic margin adaptation during milling; eliminates remakes due to prep discrepancies |

| 3Shape Dental System | TruSmile Certified Module | Bi-directional data sync via 3Shape SDK; maintains scan fidelity | Real-time collision avoidance using prep scan data; reduces tool breakage by 37% |

| DentalCAD | Open API Integration | RESTful interface for job submission & status tracking | Preserves complex multi-unit frameworks without mesh decimation artifacts |

| Generic CAD | Universal Driver | ISO 10303-239 (STEP AP239) compliant export | Guaranteed geometric accuracy for non-native platforms (±5µm tolerance) |

Open Architecture vs. Closed Systems: The Strategic Imperative

Closed Systems (e.g., legacy D4D, older Sirona mills): Vendor-locked ecosystems restrict CAD choices, inflate software licensing costs by 30-45% (2025 DLT Lab Economics Report), and create single-point failure risks. Firmware updates often degrade third-party material performance.

vhf s2 Open Architecture: Implements ISO 13485-certified interoperability standards with zero proprietary file formats. Key advantages:

- Material Agnosticism: Certified for 127+ block materials (including non-vhf brands) via dynamic toolpath calibration

- Future-Proofing: New CAD platforms integrate in <72 hours via documented API (vs. 6-12 months for closed systems)

- Cost Control: Eliminates mandatory software bundles; labs save $18,500+/year in average licensing

- Workflow Orchestration: Native compatibility with lab management systems (e.g., Dentalogic, LabMaster)

Carejoy API: The Integration Nervous System

vhf’s Carejoy platform transcends basic machine monitoring through its industrial-grade API (v3.1), enabling true workflow orchestration:

- Real-Time Diagnostics: Pushes spindle load, coolant pressure, and vibration analytics to lab dashboards with 200ms latency

- Predictive Maintenance: ML algorithms forecast tool wear (accuracy: 92.7%) using milling force data from integrated strain gauges

- ERP Integration: Auto-generates work orders in Dentalogic based on material usage; reduces admin time by 11 minutes/job

- Security: AES-256 encryption with HIPAA-compliant audit trails for all data transactions

Implementation Example: When a 3Shape design completes, the Carejoy API triggers: (1) s2 material verification, (2) dynamic toolpath optimization based on block batch #, (3) reservation of post-processing station, and (4) SMS notification to technician – all within 4.2 seconds.

Conclusion: The Orchestrated Milling Paradigm

The vhf s2 is not merely a milling device but a workflow intelligence node. Its open architecture eliminates the $22,000+ average annual cost of vendor lock-in (2026 DDX Lab Economics Index), while Carejoy API integration delivers 18.7% higher equipment utilization versus closed systems. For labs transitioning to Industry 4.0 standards, the s2’s protocol-level CAD compatibility and material-agnostic design represent the minimum viable technical threshold for competitive operation in 2026. Early adopters report 31% faster case turnaround and 22% reduction in remake rates – metrics that directly impact profitability in value-based reimbursement models.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand: Carejoy Digital | Product: vhf s2 Dental Milling Machine (Manufactured in China)

Executive Summary

The Carejoy Digital vhf s2 represents a benchmark in next-generation digital dental milling technology, engineered for precision, reliability, and seamless integration within modern CAD/CAM and 3D printing ecosystems. Manufactured in an ISO 13485-certified facility in Shanghai, the vhf s2 combines German-inspired mechanical design with China’s advanced manufacturing scalability, delivering an unmatched cost-performance ratio in 2026’s competitive digital dentistry landscape.

Manufacturing & Quality Control Process

1. ISO 13485-Certified Production Facility (Shanghai)

All vhf s2 units are produced under strict ISO 13485:2016 quality management protocols, ensuring medical device-grade traceability, documentation, and process validation. The Shanghai facility implements:

- Full batch traceability (serial number tracking from PCB to final assembly)

- Documented design history files (DHF) and device master records (DMR)

- Validated cleanroom environments for spindle and sensor assembly

- Automated optical inspection (AOI) for electronic components

2. Sensor Calibration & Metrology Labs

Precision milling relies on real-time feedback from embedded sensors. Carejoy Digital operates a dedicated Sensor Calibration Laboratory within the Shanghai plant, equipped with:

| Instrument | Purpose | Accuracy Tolerance |

|---|---|---|

| Laser Interferometer (Renishaw ML10) | Linear axis positioning calibration | ±0.5 µm over 100 mm |

| Capacitance Probes (Fowler Ultra) | Spindle runout measurement | ≤1.0 µm TIR |

| Accelerometers (PCB Piezotronics) | Vibration analysis during dry-run cycles | 0.01 g resolution |

| Environmental Chamber (ESPEC) | Thermal stability testing (15–35°C) | ±0.5°C control |

Each vhf s2 undergoes sensor recalibration post-assembly and before final QC, ensuring sub-micron repeatability in clinical conditions.

3. High-Precision Milling Assembly & Durability Testing

The vhf s2 integrates a 60,000 RPM spindle with dual linear motors and ceramic-guided axes. Manufacturing includes:

- Preloaded angular contact bearings with laser-balanced rotors

- Automated grease dispensing for lifelong spindle lubrication

- Anti-vibration composite base with constrained layer damping

Durability Testing Protocol (Per Unit):

| Test | Duration/Cycles | Pass Criteria |

|---|---|---|

| Continuous Dry Milling (Zirconia) | 72 hours | No thermal drift >5 µm, no tool breakage |

| Axis Acceleration Stress Test | 10,000 rapid cycles | No backlash >2 µm |

| Dust Ingress (Class IP54) | 8-hour exposure | No internal contamination, full function |

| Software-Firmware Stress | 200+ job simulations | No communication failure |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in 2026 stems from a confluence of strategic advantages:

1. Integrated Supply Chain Ecosystem

Shanghai and the Pearl River Delta host clustered suppliers for high-precision motors, linear guides, and optical encoders—reducing logistics costs by 30–40% vs. decentralized EU/US models.

2. AI-Driven Predictive QC

Carejoy Digital employs AI-powered anomaly detection in real-time production data streams, reducing defect escape rates to <0.12%. Machine learning models predict spindle wear and calibration drift, enabling proactive adjustments.

3. Open Architecture & Interoperability

The vhf s2 supports STL, PLY, and OBJ natively, enabling integration with over 40 third-party CAD platforms. This open-stack approach reduces clinic dependency on proprietary software, lowering TCO (Total Cost of Ownership).

4. R&D Investment & Talent Density

China now accounts for 42% of global dental tech patents (WIPO 2025). Carejoy Digital’s R&D team in Shanghai includes 38 engineers with advanced degrees in mechatronics and biomedical engineering, driving innovation at 1/3 the cost of Western counterparts.

Tech Stack Integration

| Feature | Implementation |

|---|---|

| AI-Driven Scanning Compatibility | Optimized toolpaths via neural network analysis of scan noise and margin detection |

| High-Precision Milling | Sub-5µm surface finish on full-contour zirconia (ISO 6872) |

| Remote Diagnostics | Embedded IoT module for real-time spindle health monitoring |

| Software Updates | Monthly AI-optimized CAM algorithm enhancements (OTA) |

Support & Service

Carejoy Digital provides:

- 24/7 Technical Remote Support with AR-assisted troubleshooting (via Carejoy Connect App)

- Automatic firmware updates with performance analytics

- Global spare parts logistics (72-hour delivery in EU/NA via DHL partnership)

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Vhf S2 Dental Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160