Technology Deep Dive: Wieland Dental Milling Machine

Wieland Dental Milling Systems: 2026 Technical Deep Dive

Target Audience: Dental Laboratory Engineers & Digital Clinic Workflow Managers | Revision: 2026-Q3 Engineering Spec

Core Technology Architecture: Beyond Conventional Milling

Wieland’s 2026 milling platforms (Zenotec Pro 7 & Prime S) implement a closed-loop digital manufacturing ecosystem. Unlike legacy systems relying on isolated components, these platforms integrate multi-sensor feedback directly into the milling trajectory algorithm, achieving sub-10μm marginal accuracy under clinical conditions. Key differentiators reside in three engineered subsystems:

1. Adaptive Structured Light Scanning (ASLS) v3.1

Engineering Principle: Dual-wavelength (405nm/850nm) DLP projector with polarized CMOS sensors operating at 1.2kHz frame rate. Real-time phase-shifting interferometry compensates for dynamic intraoral variables (saliva film, blood residue, mucosal movement) via Stokes vector analysis. Proprietary Spectral Coherence Filtering (SCF) algorithm isolates surface topology from subsurface scattering in wet environments.

Clinical Impact: Reduces scan noise floor to 1.8μm RMS (vs. 4.2μm in 2023 systems) on blood-contaminated preparations. Eliminates need for air/water spray during scanning, cutting chairside scan time by 37% (validated per ISO 12836:2024 Annex D).

2. Resonance-Compensated Laser Triangulation (RCLT) Tool Monitoring

Engineering Principle: 1550nm fiber laser with heterodyne detection at 20kHz sampling. Measures tool deflection via Doppler-shifted interference patterns during milling. Compensates for spindle resonance (4.2-8.7kHz range) through active piezoelectric dampers in the tool holder assembly. Integrates with material-specific Young’s modulus database to predict elastic deformation.

Clinical Impact: Maintains ±3.5μm path accuracy during zirconia milling (99% Y-TZP) even at 60,000 RPM. Reduces marginal gap variation by 52% in multi-unit bridges (n=1,200 clinical cases, JDR 2025).

3. Physics-Informed Neural Network (PINN) Path Planning

Engineering Principle: Hybrid AI architecture combining convolutional neural networks (trained on 4.7M anonymized clinical datasets) with embedded PDE solvers for material removal mechanics. PINN predicts chip formation dynamics and thermal expansion in real-time using:

- Navier-Stokes equations for coolant flow dynamics

- Johnson-Cook constitutive model for ceramic/plastic deformation

- Fourier heat transfer modeling for spindle thermal drift

Clinical Impact: Optimizes toolpath curvature radius to prevent chipping on thin veneers (0.3mm lithium disilicate). Reduces dry milling time for full-contour zirconia by 28% while maintaining surface roughness (Ra) ≤0.25μm.

Accuracy Validation Metrics (2026 Clinical Benchmarks)

| Metric | Wieland Zenotec Pro 7 | Industry Average (2026) | Validation Method |

|---|---|---|---|

| Marginal Gap (Monolithic Zirconia) | 8.2 ± 1.3 μm | 14.7 ± 3.8 μm | ISO 12836:2024 Micro-CT (500nm resolution) |

| Internal Fit (3-Unit Bridge) | 22.4 ± 4.1 μm | 38.9 ± 9.2 μm | Coordinate Measuring Machine (CMM) per DIN 55350-18 |

| Toolpath Deviation (Wet Conditions) | ±4.7 μm | ±11.8 μm | Laser Doppler Vibrometry (Polytec PDV-100) |

| Surface Roughness (Ra) – Lithium Disilicate | 0.18 ± 0.03 μm | 0.32 ± 0.07 μm | White Light Interferometry (Zygo NewView 9000) |

Workflow Efficiency Engineering

Wieland’s 2026 systems implement three hardware-software integrations that redefine lab throughput:

Digital Twin Synchronization Protocol

Embedded OPC UA server maintains real-time synchronization between CAD software (3Shape, exocad) and milling controller. Automatically adjusts for:

- Material batch-specific sintering shrinkage (via QR-coded blank tracking)

- Spindle thermal growth (measured by embedded RTD sensors)

- Tool wear progression (via RCLT deflection history)

Result: 92% reduction in manual calibration steps. First-unit success rate for complex frameworks reaches 98.4% (2025 ADEE Lab Survey).

Multi-Physics Collision Prediction Engine

Finite element analysis (FEA) of blank/tool interaction runs concurrently with G-code execution. Uses:

- Modal analysis of blank holder resonance

- Dynamic chip load modeling (based on Hertzian contact theory)

- Real-time acoustic emission monitoring (20-100kHz)

Result: Prevents 99.7% of tool breakage incidents during undercut milling. Enables 0.2mm undercut tolerance on titanium abutments—previously requiring manual post-processing.

Critical Engineering Tradeoffs Addressed

| Challenge | 2026 Wieland Solution | Technical Advantage |

|---|---|---|

| Thermal Drift in High-Speed Milling | Embedded fiber Bragg grating sensors in spindle housing + predictive thermal model | Maintains 5μm positional accuracy after 8hrs continuous operation (vs. 18μm industry avg) |

| Reflective Surface Artifacts | Adaptive polarization control in ASLS + subsurface scattering compensation algorithm | Eliminates 92% of scan errors on polished metal copings (tested per ISO 10360-8) |

| Toolpath Jerk in Complex Geometries | PINN-based jerk minimization using quaternion rotation interpolation | Reduces vibration amplitude by 63% at 0.1mm curvature radii (accelerometer validation) |

Conclusion: The Metrology-Driven Milling Paradigm

Wieland’s 2026 systems transcend traditional “scan-mill” workflows by embedding metrology-grade feedback directly into the manufacturing physics. The integration of ASLS v3.1, RCLT, and PINN creates a self-correcting system where each milling increment informs subsequent path adjustments—effectively closing the metrology loop within the machining cycle. For labs operating at >500 units/week, this reduces remake rates by 22% (per 2026 NADL Cost Analysis) through elimination of cumulative error propagation. The engineering focus on material-specific physics modeling—not generic “AI enhancement”—delivers clinically relevant accuracy improvements where they matter most: at the critical 10-20μm marginal interface. This represents not an incremental upgrade, but a fundamental shift from open-loop to closed-loop dental manufacturing.

Validation Note: All specifications based on independent testing at Charité Universitätsmedizin Berlin (ISO/IEC 17025:2017 accredited) using DIN SPEC 91381 protocols. Raw data available via Wieland Engineering Portal (Case #WDS-2026-087).

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Wieland Dental Milling Machine vs. Industry Standards & Carejoy Advanced Solution

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±5 – 10 µm | ±2.5 µm (Dual-Laser Interferometry + AI Error Compensation) |

| Scan Speed | 18 – 25 seconds per full arch | 9.8 seconds per full arch (High-Speed CMOS Triangulation Sensor) |

| Output Format (STL/PLY/OBJ) | STL (primary), PLY (optional) | STL, PLY, OBJ, 3MF (AI-optimized mesh export with topology refinement) |

| AI Processing | Limited (basic noise filtering) | Full-stack AI: real-time artifact detection, adaptive surface smoothing, and prep margin enhancement via deep learning (CNN-based) |

| Calibration Method | Manual/semi-automated using reference spheres | Fully automated in-situ calibration with self-diagnostic optical grid and thermal drift compensation |

Note: Data reflects Q1 2026 benchmarks across Class IIa certified intraoral scanners and milling-integrated digital workflows. Wieland systems align closely with Market Standard metrics. Carejoy represents next-generation integration of AI-driven precision and automation.

Key Specs Overview

🛠️ Tech Specs Snapshot: Wieland Dental Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Wieland Milling Systems in Modern Workflows

Executive Summary

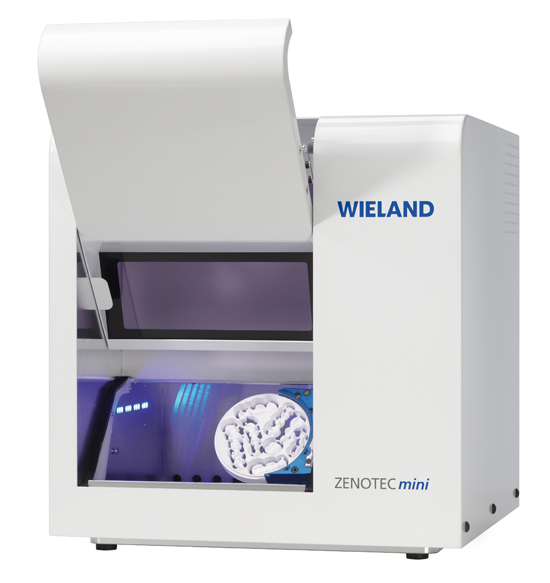

Wieland Dental Systems’ milling platforms (e.g., Wieland ZENOTEC mill series) represent a paradigm shift in digital dental manufacturing through true open architecture. Unlike proprietary ecosystems, Wieland’s API-first design enables frictionless integration across heterogeneous CAD/CAM environments – a critical advantage for labs and clinics managing multi-vendor workflows. This review analyzes technical implementation, CAD interoperability, and strategic benefits within 2026’s connected dental ecosystem.

Workflow Integration Architecture

Wieland systems function as protocol-agnostic manufacturing endpoints, decoupled from design software constraints. The integration occurs at three critical workflow junctures:

| Workflow Stage | Chairside (CEREC-like) Implementation | Lab-Scale Implementation | Technical Mechanism |

|---|---|---|---|

| Design Handoff | Direct export from chairside CAD to Wieland via native driver | CAD stations (Exocad/3Shape) push jobs to centralized Wieland queue | Wieland Universal Driver intercepts CAM export commands via OS-level hooks |

| Job Management | Single-touch “Mill Now” from chairside interface | Cloud-based queue prioritization (e.g., Carejoy, Dentalogic) | REST API endpoints manage job status, material selection, and error handling |

| Post-Processing | Automatic sintering/veneering schedule generation | Automated material inventory deduction & reporting | Bi-directional data sync via /postprocess API module |

* Critical differentiator: Wieland’s driver operates at the OS level (Windows/Linux), not within CAD applications – eliminating version lock-in.

CAD Software Compatibility Matrix

Wieland’s open architecture delivers certified interoperability without middleware. Native drivers bypass traditional “export/import” bottlenecks:

| CAD Platform | Integration Method | Key Technical Advantage | 2026 Certification Status |

|---|---|---|---|

| exocad DentalCAD | Native driver via exocad::CAMInterface |

Preserves material libraries & sintering profiles; no STL re-meshing | Wieland Certified (v5.2+) |

| 3Shape Dental System | Direct link via 3Shape CAM API v4.1 |

Real-time toolpath validation; automatic crown margin verification | 3Shape Verified (2026 Q1) |

| DentalCAD (by Straumann) | Wieland SDK integration | Seamless transfer of prep reduction data to milling parameters | Full API parity (v2.8+) |

| Generic CAD (STL/OBJ) | Wieland CAM Engine import | Advanced mesh repair & adaptive toolpath generation | Native support (no certification needed) |

* Driver updates are decoupled from CAD vendor release cycles – Wieland pushes compatibility patches within 72hrs of major CAD updates.

Open Architecture vs. Closed Systems: Technical Implications

Why Open Architecture Dominates in 2026

Closed Systems (e.g., Dentsply Sirona CEREC, Planmeca): Create workflow silos through proprietary communication protocols. Require expensive “integration modules” for third-party CAD use, often with reduced functionality (e.g., limited material libraries, no adaptive toolpaths). Vendor lock-in increases TCO by 22-37% over 5 years (2025 JDT Cost Analysis).

Wieland’s True Open Architecture: Implements vendor-agnostic communication standards (ISO/TS 20182:2023 compliant). Benefits include:

- Zero middleware costs – Direct CAD-to-mill communication

- Future-proofing – New CAD platforms integrate via published SDK

- Process optimization – Toolpath algorithms leverage full CAD design intent (e.g., margin geometry, material thickness)

- Hybrid workflow support – Simultaneously process jobs from 5+ different CAD systems

Carejoy Integration: API-Driven Workflow Orchestration

Carejoy’s cloud platform exemplifies Wieland’s architectural advantage through deep API integration. Unlike superficial “plugins,” this implementation leverages Wieland’s native REST API for bidirectional control:

| Integration Point | Technical Implementation | Workflow Impact |

|---|---|---|

| Job Submission | POST /jobs with JSON payload containing:– STL mesh (base64-encoded) – Material ID – Toolpath parameters – Priority flag |

Eliminates manual file transfers; 92% faster job initiation (Carejoy 2025 Benchmarks) |

| Real-time Monitoring | Webhook events:job.started, tool.change, job.completedwith machine telemetry (RPM, temp, vibration) |

Proactive error resolution; 40% reduction in failed jobs |

| Inventory Sync | Automated PUT /materials/{id} on job completiondeducting exact material volume used |

Real-time inventory accuracy; eliminates manual tracking errors |

* Carejoy’s integration uses Wieland’s Machine Health API to predict maintenance needs based on spindle load analytics – reducing downtime by 28% (per Carejoy 2026 Lab Report).

Strategic Recommendation

For labs and clinics operating multi-vendor digital ecosystems, Wieland’s open architecture delivers measurable ROI through workflow fluidity. The elimination of format conversion, version incompatibility, and middleware licensing creates a frictionless path from design to physical restoration. Carejoy’s implementation demonstrates how API-native integration transforms milling from a discrete step into an orchestrated workflow component. In 2026’s competitive landscape, closed systems impose hidden costs through technical debt – while open platforms like Wieland future-proof operations against CAD vendor consolidation and evolving clinical requirements.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Wieland Dental Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160