Introduction: Navigating the Global Market for dental implants cons

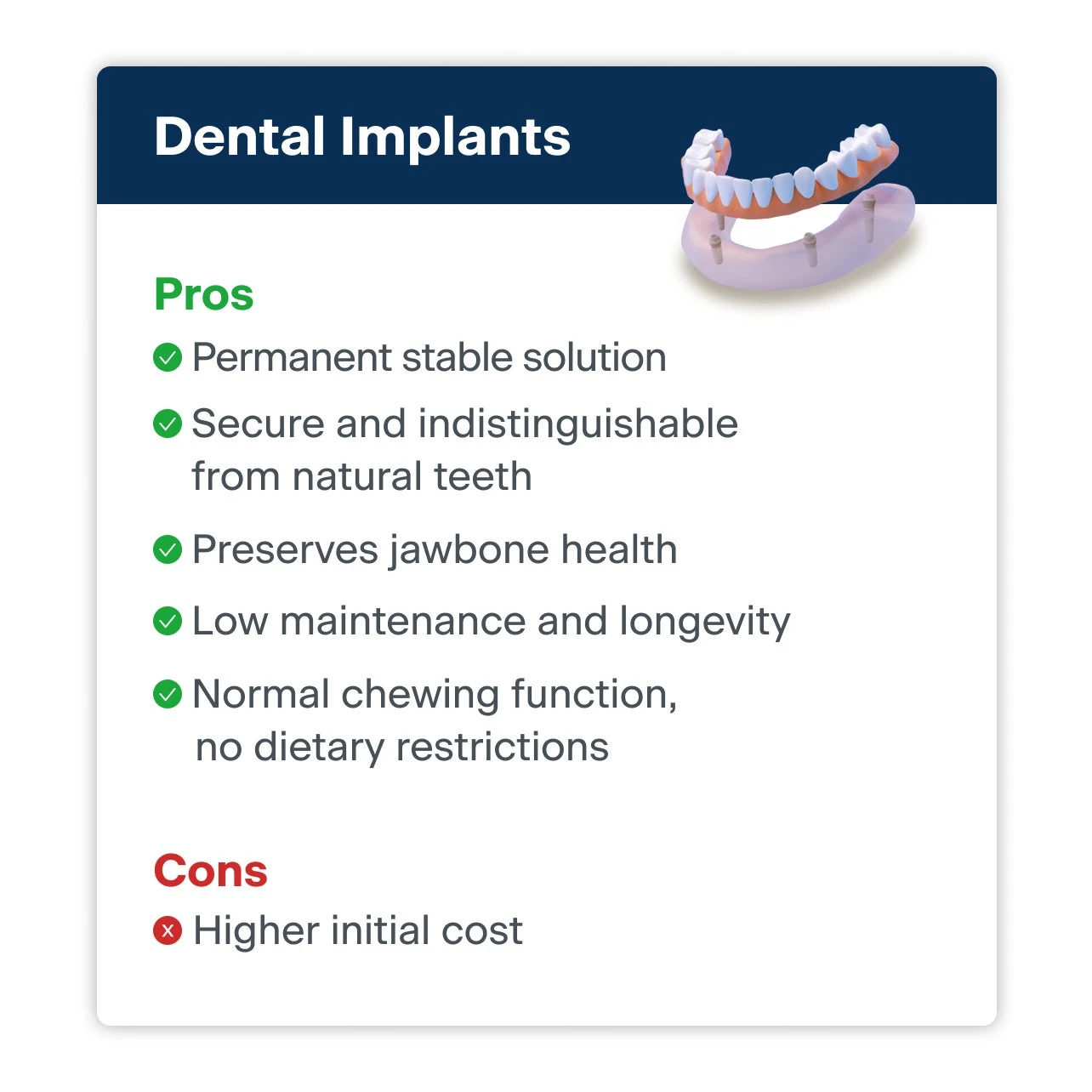

Navigating the global market for dental implants requires a thorough understanding of both the advantages and the potential drawbacks associated with these critical medical devices. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, it is essential to grasp the implications of choosing dental implants that may not meet the specific needs of your market or clientele. This guide delves into the cons of dental implants, illuminating the challenges and risks that can arise throughout the sourcing and implementation process.

The scope of this guide is comprehensive, covering various aspects that influence decision-making. Buyers will find detailed insights into the types of dental implants available, including materials and manufacturing quality control standards. Furthermore, we will explore supplier options, cost considerations, and market trends, equipping you with the knowledge necessary to make informed sourcing decisions.

By understanding the potential pitfalls associated with dental implants, B2B buyers can better navigate supplier relationships, negotiate terms, and ultimately enhance the quality of care provided to patients. This guide serves as an essential resource, empowering you to mitigate risks and strategically approach procurement in the dental implant sector. With the right information, you can ensure that your organization remains competitive and responsive to the evolving demands of the global dental market.

Understanding dental implants cons Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Endosteal Implants | Placed directly into the jawbone; most common type | General dentistry, oral surgery | Pros: Highly stable, suitable for most patients. Cons: Requires sufficient bone density; surgical risks. |

| Subperiosteal Implants | Positioned under the gum but above the jawbone | Dental restoration for limited bone | Pros: Good for patients with low bone density. Cons: Less stable than endosteal; more complex procedure. |

| Zygomatic Implants | Anchored in the cheekbone; used when jawbone is insufficient | Advanced dental surgeries | Pros: Ideal for patients with severe bone loss. Cons: Requires specialized training; higher costs. |

| Mini Implants | Smaller diameter than traditional implants; less invasive | Temporary or transitional solutions | Pros: Quick placement, minimal recovery time. Cons: Lower stability; not suitable for all cases. |

| All-on-4 Implants | Four implants support an entire arch of teeth | Full-arch restorations | Pros: Cost-effective for full mouth restoration. Cons: May require bone grafting; not suitable for all patients. |

Endosteal Implants

Endosteal implants are the most prevalent type, inserted directly into the jawbone. They are ideal for patients with adequate bone density and are widely used in general dentistry and oral surgery. When considering these implants, buyers should evaluate the surgical risks and the need for pre-operative assessments, such as bone density tests, to ensure successful outcomes.

Subperiosteal Implants

Subperiosteal implants are placed under the gum tissue but above the jawbone, making them a viable option for patients with insufficient jawbone height. These implants are commonly used in dental restoration where bone grafting is not feasible. Buyers should consider the complexity of the procedure and the potential for less stability compared to endosteal implants, which may affect long-term success.

Zygomatic Implants

Zygomatic implants are anchored in the cheekbone and are designed for patients with significant jawbone loss, often following tooth loss or severe periodontal disease. These implants require specialized training and are suitable for complex cases where traditional implants cannot be used. B2B buyers should factor in the higher costs and the need for skilled practitioners when considering zygomatic implants for their clients.

Mini Implants

Mini implants have a smaller diameter than traditional implants and are less invasive, making them suitable for quick placement and minimal recovery. They serve well as temporary or transitional solutions, particularly in patients who may not be ready for full implants. However, their lower stability compared to standard implants means they may not be suitable for all cases, and buyers should assess patient needs carefully.

All-on-4 Implants

All-on-4 implants utilize four strategically placed implants to support an entire arch of prosthetic teeth, offering a cost-effective solution for full mouth restoration. This method can significantly reduce the need for bone grafting and is popular among patients seeking a complete dental solution. Buyers should be aware of the potential need for additional procedures and the importance of thorough patient evaluation to ensure the best fit for this type of restoration.

Related Video: Dental Implants 101: What You NEED to Know! Part 1 (Implant Basics)

Key Industrial Applications of dental implants cons

| Industry/Sector | Specific Application of dental implants cons | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Managing patient expectations and treatment costs | Enhances patient satisfaction and retention | Supplier reliability and warranty terms |

| Medical Device Manufacturing | Addressing regulatory compliance issues | Ensures product safety and market access | Understanding local regulations and certifications |

| Dental Tourism | Evaluating treatment options and costs | Attracts international patients seeking affordability | Quality assurance and post-treatment support |

| Insurance Providers | Assessing risk associated with dental implants | Enables accurate premium pricing and policy structuring | Data on complication rates and recovery statistics |

| Research Institutions | Investigating long-term outcomes of implants | Contributes to evidence-based practices in dentistry | Access to clinical data and collaboration opportunities |

Industry Applications and Insights

Dental Clinics

Dental clinics face the challenge of managing patient expectations regarding the longevity and success of dental implants. By understanding the cons associated with implants—such as potential complications and the need for ongoing maintenance—clinics can provide clearer communication about treatment outcomes. This transparency enhances patient satisfaction, leading to higher retention rates. For B2B buyers in this sector, sourcing reliable suppliers who offer warranties and comprehensive support is essential to mitigate risks.

Medical Device Manufacturing

In the realm of medical device manufacturing, regulatory compliance is a significant concern. Understanding the cons of dental implants, such as the risks of infection or implant failure, is crucial for manufacturers to ensure product safety and efficacy. This knowledge aids in developing devices that meet stringent regulatory requirements, facilitating smoother market access. B2B buyers must prioritize suppliers who are well-versed in local regulations and can provide necessary certifications.

Dental Tourism

Dental tourism is a growing industry, particularly in regions where treatment costs are lower. Buyers in this sector must evaluate the cons of dental implants, including the potential for complications that may arise from overseas treatments. By emphasizing the importance of thorough evaluations and transparent pricing, dental tourism operators can attract international patients seeking cost-effective solutions. Quality assurance and robust post-treatment support are critical sourcing considerations to ensure patient safety.

Insurance Providers

Insurance providers need to assess the risks associated with dental implants to develop accurate premium pricing and policy structuring. Understanding the cons—such as the likelihood of complications or the need for additional procedures—enables insurers to create informed coverage options. B2B buyers in this sector should seek data on complication rates and recovery statistics from suppliers to enhance their risk assessment models.

Research Institutions

Research institutions play a vital role in advancing dental practices by investigating the long-term outcomes of dental implants. By analyzing the cons of implants, such as their impact on oral health over time, researchers can contribute to evidence-based practices that improve patient care. B2B buyers in this field should focus on establishing collaborations with suppliers who can provide access to clinical data and support research initiatives.

Related Video: Full Mouth Dental Implants. What You Should Know and Cost

Strategic Material Selection Guide for dental implants cons

When selecting materials for dental implants, it’s crucial to understand the properties, advantages, and disadvantages of each option. Below, we analyze four common materials used in dental implants: titanium, zirconia, stainless steel, and polymer composites. Each material has unique characteristics that can significantly impact performance, longevity, and overall suitability for different applications in the dental field.

Titanium

Key Properties:

Titanium is known for its excellent corrosion resistance, biocompatibility, and strength-to-weight ratio. It can withstand high temperatures and pressures, making it suitable for various dental applications.

Pros & Cons:

The primary advantage of titanium is its durability and ability to integrate with bone (osseointegration). However, titanium implants can be more expensive due to the complexity of manufacturing and processing. Additionally, some patients may have allergies to titanium, which can limit its use.

Impact on Application:

Titanium is compatible with various media, including saliva and blood, making it ideal for dental implants. Its strength allows it to support significant loads, which is essential for dental prosthetics.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM F136 for titanium alloys. In regions like Europe and the Middle East, CE marking is crucial for market entry.

Zirconia

Key Properties:

Zirconia is a ceramic material that offers high strength and excellent aesthetic properties. It is resistant to wear and corrosion, making it suitable for dental applications.

Pros & Cons:

The main advantage of zirconia is its tooth-like appearance, which provides a more natural look compared to metal implants. However, zirconia can be more brittle than titanium, leading to potential fractures under stress. Additionally, the manufacturing process can be complex and costly.

Impact on Application:

Zirconia is particularly suitable for anterior (front) teeth implants where aesthetics are paramount. It is also biocompatible, reducing the risk of allergic reactions.

Considerations for International Buyers:

Buyers should look for compliance with ISO 6872 standards for dental ceramics. In South America and Africa, understanding local regulations regarding ceramic materials is essential.

Stainless Steel

Key Properties:

Stainless steel is known for its strength, corrosion resistance, and affordability. It can withstand significant pressure and is easy to fabricate.

Pros & Cons:

The key advantage of stainless steel is its cost-effectiveness, making it a popular choice for temporary implants. However, its aesthetic appeal is lower than that of titanium or zirconia, and it may cause allergic reactions in some patients.

Impact on Application:

Stainless steel is often used for temporary dental implants or in situations where cost is a significant factor. Its mechanical properties allow it to endure loads, but it may not integrate as well with bone as titanium.

Considerations for International Buyers:

Compliance with ASTM F138 standards is essential. In regions like Europe, CE marking is also required. Buyers should assess the market demand for stainless steel implants versus more expensive alternatives.

Polymer Composites

Key Properties:

Polymer composites are lightweight and can be engineered for specific mechanical properties. They offer good corrosion resistance and are often used in combination with other materials.

Pros & Cons:

The primary advantage of polymer composites is their versatility and lower cost compared to metals. However, they may not provide the same level of strength and durability as titanium or zirconia, making them less suitable for long-term implants.

Impact on Application:

These materials are often used for temporary implants or in pediatric dentistry. Their flexibility allows for a range of applications, but they may not be ideal for load-bearing situations.

Considerations for International Buyers:

Buyers should ensure compliance with ASTM D638 for plastics. Understanding local regulations in Africa and South America regarding polymer use in medical devices is also critical.

Summary Table

| Material | Typical Use Case for dental implants cons | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Permanent dental implants | Excellent osseointegration | Higher cost, potential allergies | High |

| Zirconia | Aesthetic anterior implants | Natural appearance | Brittle, complex manufacturing | Medium |

| Stainless Steel | Temporary implants | Cost-effective | Lower aesthetic appeal, allergic reactions | Low |

| Polymer Composites | Pediatric or temporary implants | Versatile and lightweight | Lower strength and durability | Low |

This strategic material selection guide provides insights into the pros and cons of various materials used in dental implants, aiding international B2B buyers in making informed decisions based on regional compliance and market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for dental implants cons

The manufacturing of dental implants is a critical process that must adhere to stringent quality assurance standards to ensure safety and efficacy. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of these processes is vital for making informed procurement decisions. This section delves into the typical manufacturing stages, key techniques employed, quality control measures, and how buyers can verify supplier compliance with international standards.

Manufacturing Processes

The manufacturing of dental implants typically involves four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation

– Selection of Raw Materials: Dental implants are primarily made from biocompatible materials such as titanium and its alloys, which offer strength and resistance to corrosion. The selection process involves sourcing high-grade materials that meet specific international standards.

– Pre-treatment: Raw materials often undergo pre-treatment processes to remove impurities and enhance their physical properties. This may include cleaning and surface treatments to ensure optimal performance during subsequent stages. -

Forming

– Machining: This is a crucial step where the implant is shaped into its final form using CNC (Computer Numerical Control) machines. Precision is paramount, as even minor deviations can affect the fit and function of the implant.

– Additive Manufacturing: Increasingly, manufacturers are adopting 3D printing technologies for creating complex geometries that are difficult to achieve through traditional methods. This allows for customized implants tailored to individual patient needs.

Illustrative Image (Source: Google Search)

-

Assembly

– Component Integration: In cases where implants consist of multiple parts (e.g., abutments), assembly involves precise fitting of these components. This stage may include welding or fastening techniques to ensure structural integrity.

– Sterilization: Before packaging, all assembled implants undergo sterilization processes to eliminate any potential contaminants, adhering to health regulations. -

Finishing

– Surface Treatment: The final surface treatment of implants can significantly influence osseointegration—the process by which bone integrates with the implant. Techniques such as sandblasting, acid etching, or coating with bioactive materials are common.

– Quality Check: The finished implants undergo a final inspection to ensure they meet all specifications before they are packaged and shipped.

Quality Assurance

Quality assurance in dental implant manufacturing is governed by several international standards, such as ISO 9001 for quality management systems and ISO 13485 specific to medical devices. Additional certifications like CE marking in Europe or FDA approval in the United States are also crucial for compliance.

Key Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– This initial checkpoint focuses on the quality of incoming raw materials. Suppliers must provide certificates of analysis (CoA) to confirm that materials meet specified standards. -

In-Process Quality Control (IPQC)

– Throughout the manufacturing process, ongoing inspections are conducted to monitor critical parameters. This includes checking dimensions, surface quality, and mechanical properties at various stages. -

Final Quality Control (FQC)

– Upon completion, every batch of implants undergoes rigorous testing. This includes functional tests to ensure that the implants can withstand the stresses they will encounter in the human body.

Common Testing Methods

- Mechanical Testing: Includes tensile tests, fatigue tests, and hardness tests to ensure the material can endure physiological loads.

- Biocompatibility Testing: Assesses how the materials interact with human tissues, ensuring safety and effectiveness.

- Sterility Testing: Ensures that the implants are free from microorganisms.

Verifying Supplier Quality Control

For B2B buyers, particularly those operating internationally, verifying a supplier’s quality control measures is essential. Here are actionable steps:

-

Conduct Supplier Audits

– Regular audits help assess the supplier’s adherence to quality standards. Auditors should evaluate the manufacturing process, quality control systems, and certifications. -

Request Quality Reports

– Suppliers should provide comprehensive quality documentation, including test results, compliance certificates, and quality management system details. -

Engage Third-Party Inspectors

– Utilizing third-party inspection services can provide unbiased evaluations of manufacturing facilities and processes. This can be particularly beneficial for buyers in regions with less stringent regulatory oversight.

Compliance Nuances for International Buyers

International B2B buyers need to be aware of the regulatory differences across regions:

- Africa and South America: Buyers should be cautious of varying local regulations regarding medical devices. It’s advisable to engage local consultants who are familiar with the regulatory landscape.

- Middle East: Countries like Saudi Arabia and the UAE have specific regulatory requirements, including local agency approvals (e.g., SFDA). Understanding these nuances can prevent delays in importation.

- Europe: Compliance with CE marking is essential. Buyers must ensure that suppliers possess the necessary documentation to facilitate smooth market entry.

Conclusion

Understanding the manufacturing processes and quality assurance measures for dental implants is crucial for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, alongside robust quality control checkpoints, buyers can make informed decisions. By verifying supplier compliance through audits, quality reports, and third-party inspections, businesses can mitigate risks associated with procurement in the dental implant market.

Related Video: How Its Made Titanium Dental Implants

Comprehensive Cost and Pricing Analysis for dental implants cons Sourcing

Understanding the cost structure and pricing dynamics of dental implants is crucial for B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe. This analysis will provide insights into the various components that contribute to the overall cost of dental implants, along with actionable strategies for procurement.

Cost Components

-

Materials: The choice of materials significantly influences the cost. Common materials used in dental implants include titanium and zirconia. Titanium is generally more affordable but may not offer the same aesthetic appeal as zirconia, which is often preferred for visible areas.

-

Labor: Labor costs vary by region and are influenced by local wage standards and the complexity of the implant design. Skilled labor is necessary for both the manufacturing process and the surgical procedures involved in implant placement.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. High-quality manufacturing environments, such as clean rooms, are essential for producing dental implants and can add to overhead costs.

-

Tooling: The initial setup for manufacturing implants requires specialized tooling. These upfront costs can be significant, particularly for custom designs or small production runs.

-

Quality Control (QC): Rigorous QC processes are mandatory for medical devices, including dental implants. Compliance with international standards (e.g., ISO 13485) can incur additional costs but is essential for ensuring product reliability and safety.

Illustrative Image (Source: Google Search)

-

Logistics: Shipping and handling costs must also be considered, especially for international transactions. Factors such as distance, weight, and shipping methods will influence logistics expenses.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on competition, brand reputation, and market demand.

Price Influencers

Several factors can influence the pricing of dental implants:

-

Volume/MOQ: Larger orders often qualify for bulk discounts, making it essential to negotiate minimum order quantities (MOQ) that align with your business needs.

-

Specifications/Customization: Custom implants designed for specific patient needs may increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials: As mentioned, the choice of materials will affect pricing. Buyers should assess the trade-offs between cost, durability, and aesthetics.

-

Quality/Certifications: Products with certifications (e.g., CE, FDA) may come at a premium. However, these certifications can be crucial for compliance and customer trust.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with proven track records may charge more but offer better quality assurance.

-

Incoterms: Understanding Incoterms is vital for managing shipping responsibilities and costs. Different terms can significantly affect the total landed cost of the implants.

Buyer Tips

-

Negotiation: Engage suppliers in discussions to negotiate better terms. Leverage your purchasing power, especially if committing to larger volumes.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, shipping, customs, and future maintenance costs. This holistic view can lead to more informed buying decisions.

-

Pricing Nuances: Be aware that pricing can vary significantly across regions. For instance, suppliers in Europe may have higher prices due to stricter regulations compared to those in South America or Africa.

-

Research and Benchmarking: Conduct thorough market research to benchmark prices and quality across different suppliers. This will help in identifying competitive pricing and potential cost savings.

- Supplier Diversification: Avoid relying on a single supplier. Diversifying your supplier base can mitigate risks and provide leverage in negotiations.

Disclaimer

Prices for dental implants can vary widely based on numerous factors. The information provided here is indicative and should not be considered as final pricing. Always consult with suppliers for accurate quotes tailored to your specific needs.

Essential Technical Properties and Trade Terminology for dental implants cons

Key Technical Properties of Dental Implants

Understanding the technical properties of dental implants is crucial for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. Here are some essential specifications that impact product quality and performance:

-

Material Grade: Dental implants are commonly made from titanium or zirconia. Titanium is favored for its biocompatibility and strength, while zirconia offers a more aesthetic, tooth-like appearance. Buyers should ensure that the implants meet industry standards such as ISO 13485 for medical devices, which guarantees quality management systems in manufacturing.

-

Surface Treatment: The surface of the implant can significantly affect osseointegration (the process by which the implant bonds with the jawbone). Treatments such as sandblasting, acid etching, or coating with hydroxyapatite enhance the surface roughness, promoting better integration. Buyers should inquire about surface treatment processes to ensure optimal implant performance.

-

Tolerance Levels: Tolerance refers to the allowable variation in the dimensions of the implant. Precise tolerances are critical to ensure a proper fit and function within the dental arch. High tolerance levels can minimize complications and improve patient outcomes, making it an essential specification for buyers to consider.

-

Load-Bearing Capacity: This property indicates how much force the implant can withstand without failing. Load-bearing capacity is vital for the longevity of the implant, as it must endure the forces exerted during chewing. Buyers should seek implants that have been tested for load-bearing capacity under realistic conditions.

-

Corrosion Resistance: Implants are exposed to oral fluids, making corrosion resistance a key property. Titanium implants, for example, are known for their excellent resistance to corrosion, which is essential for maintaining implant integrity over time. Buyers should ensure the materials used have been tested for corrosion resistance.

Common Trade Terminology in Dental Implants

Familiarity with industry jargon is essential for effective communication and negotiation in the dental implant market. Here are some important terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that manufacture products that are branded and sold by another company. In the context of dental implants, understanding the OEM can help buyers assess the quality and reputation of the products being offered.

-

MOQ (Minimum Order Quantity): MOQ is the smallest number of units that a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for inventory management and budgeting. It can also indicate the supplier’s production capabilities and flexibility.

-

RFQ (Request for Quotation): An RFQ is a formal request sent to suppliers asking for price quotes on specific products or services. This term is essential for buyers to understand as it helps them compare prices and negotiate better deals.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in a transaction, including shipping and delivery. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Buyers should be familiar with Incoterms to ensure clarity in trade agreements and avoid misunderstandings.

-

CE Marking: In Europe, the CE mark indicates that a product meets EU safety, health, and environmental protection standards. For buyers in Europe, verifying CE marking is essential to ensure compliance and marketability.

-

Regulatory Compliance: This term refers to the adherence to laws and regulations governing the manufacture and sale of dental implants. Understanding the regulatory landscape in different regions (like FDA regulations in the US or CDSCO in India) is vital for buyers to ensure that they are sourcing compliant products.

By mastering these technical properties and industry terms, B2B buyers can make informed decisions, ensuring they procure high-quality dental implants that meet both regulatory standards and patient needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dental implants cons Sector

Market Overview & Key Trends

The global dental implants market is experiencing significant growth, driven by the increasing prevalence of dental diseases and the rising demand for cosmetic dentistry. Key market dynamics include advancements in implant technology, such as the development of bioactive materials and 3D printing, which are revolutionizing the way implants are designed and manufactured. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these trends is crucial for making informed sourcing decisions.

Emerging trends also highlight the growing importance of digital dentistry. Technologies like CAD/CAM (Computer-Aided Design and Computer-Aided Manufacturing) are streamlining the production process, enabling faster and more precise dental implant solutions. Additionally, the rise of dental tourism in regions such as Turkey, Mexico, and Poland offers B2B buyers opportunities to source high-quality implants at competitive prices, catering to a growing global clientele seeking affordability without compromising quality.

Another significant driver is the increasing focus on patient-centered care, which is pushing manufacturers to innovate and improve the overall patient experience. As patient preferences evolve, suppliers who can adapt their offerings to meet these needs will gain a competitive edge. For B2B buyers, staying abreast of these market trends is essential for aligning their procurement strategies with future demands.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central theme in the dental implants sector. The environmental impact of dental manufacturing processes—particularly in waste management and resource consumption—has prompted many companies to adopt greener practices. For B2B buyers, sourcing from manufacturers that prioritize sustainability can enhance their brand reputation and appeal to environmentally conscious customers.

Ethical sourcing is equally important, as it involves ensuring that materials used in dental implants are obtained through responsible practices. This includes verifying supply chains for compliance with labor standards and environmental regulations. Buyers should seek suppliers that have obtained certifications such as ISO 14001 for environmental management or ISO 13485 for quality management in medical devices. These certifications not only demonstrate a commitment to sustainability but also assure buyers of the quality and safety of the products they are sourcing.

Incorporating sustainable practices and ethical sourcing into procurement strategies can create a competitive advantage, particularly in markets where consumers are increasingly valuing corporate responsibility.

Brief Evolution/History

The dental implants sector has evolved significantly over the last few decades, transitioning from rudimentary solutions to sophisticated, bio-compatible options. Early implants, made of materials like gold and stainless steel, were often rejected by the body, leading to high failure rates. However, the introduction of titanium in the 1960s marked a turning point, as it demonstrated excellent biocompatibility and osseointegration, leading to greater success in dental procedures.

In recent years, advancements in technology, including the introduction of digital workflows and 3D printing, have further refined implant manufacturing and placement processes. This evolution not only enhances the quality of dental implants but also improves patient outcomes, making it essential for B2B buyers to remain informed about historical advancements and their implications for current sourcing strategies.

Related Video: Full Mouth Dental Implants: Everything You Need to Know and Cost

Frequently Asked Questions (FAQs) for B2B Buyers of dental implants cons

-

How can I effectively vet suppliers of dental implants?

When sourcing dental implants, ensure you conduct thorough due diligence on potential suppliers. Check for certifications such as ISO 13485 and CE marking, which indicate compliance with international quality management standards. Request references from other buyers and review their track record for reliability and quality. Additionally, consider visiting the manufacturing facility if feasible, as this allows you to assess their production processes and quality control measures firsthand. -

What customization options are typically available for dental implants?

Many suppliers offer customization options for dental implants, including variations in size, shape, and materials used. Discuss your specific requirements with potential suppliers to understand their capabilities. Customization may come with additional lead times and costs, so clarify these aspects early in the negotiation process. Establishing clear specifications will help ensure that the final product meets your needs and those of your clients. -

What are the typical minimum order quantities (MOQ) and lead times for dental implants?

Minimum order quantities for dental implants can vary significantly by supplier and region. Generally, MOQs may range from 100 to 500 units, depending on the product type and customization required. Lead times typically range from 4 to 12 weeks, influenced by factors such as order size, customization, and the supplier’s production capacity. Always clarify these details upfront to align your procurement strategy with your business needs. -

What payment terms should I expect when sourcing dental implants?

Payment terms can vary widely among suppliers. Common practices include a deposit upfront (often 30-50%) with the balance due upon delivery. Some suppliers may offer more favorable terms for larger orders or established relationships. Always negotiate payment terms that protect your interests, and consider using escrow services for larger transactions to mitigate risks. Ensure that any agreed terms are documented in your purchase agreement. -

How do I ensure quality assurance and certification compliance?

Quality assurance is critical when sourcing dental implants. Request documentation for certifications such as ISO 13485 and evidence of compliance with local regulations (like FDA or CE certifications). Suppliers should provide a quality management plan detailing their processes for product testing and quality control. Regular audits and inspections can further ensure adherence to standards, so consider implementing a system for ongoing quality checks. -

What logistics considerations should I be aware of when importing dental implants?

Logistics play a crucial role in the timely delivery of dental implants. Be aware of the shipping methods used and the associated lead times. Consider customs regulations in your region, as dental implants may require specific documentation for import. Establish a reliable logistics partner familiar with medical device regulations to avoid delays. Additionally, consider using third-party logistics (3PL) services to manage inventory and distribution efficiently. -

How can I resolve disputes with suppliers effectively?

Disputes can arise over quality, delivery, or payment issues. To resolve disputes effectively, maintain clear communication with your supplier and document all interactions. Establish a formal dispute resolution process in your contract, including mediation or arbitration clauses. If issues persist, consider involving legal counsel experienced in international trade law to navigate the complexities of cross-border disputes. -

What are the common risks associated with sourcing dental implants internationally?

Sourcing dental implants internationally comes with several risks, including regulatory compliance issues, quality inconsistencies, and potential supply chain disruptions. To mitigate these risks, conduct comprehensive supplier audits and maintain a diversified supplier base. Stay informed about regulatory changes in your target markets and consider insurance options for international shipments. Building strong relationships with suppliers can also help in addressing issues proactively and ensuring smoother operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dental implants cons

In navigating the complexities of sourcing dental implants, international B2B buyers must weigh the potential drawbacks against the benefits. Key considerations include cost, regulatory compliance, and long-term reliability. While dental implants can provide significant improvements in patient quality of life, the initial investment and ongoing maintenance requirements can be substantial. Buyers should prioritize sourcing from manufacturers that adhere to international standards such as ISO 13485 and those that have a robust quality management system in place.

Strategic sourcing is essential not just for securing competitive pricing but also for ensuring the quality and safety of dental implants. Establishing strong relationships with suppliers in diverse regions—such as Africa, South America, the Middle East, and Europe—can lead to better negotiation terms and access to innovative products.

As the dental implant market continues to evolve, international buyers should remain vigilant about emerging technologies and regulatory changes that could impact sourcing decisions. By staying informed and proactive, businesses can position themselves to leverage opportunities in this dynamic field.

Engage with trusted suppliers and invest in comprehensive market research to enhance your sourcing strategy. The future of dental implant procurement is promising; seize the moment to elevate your business to new heights.