Introduction: Navigating the Global Market for dental implants vs crowns and bridges

In the ever-evolving landscape of dental healthcare, the choice between dental implants and crowns and bridges is pivotal for practitioners and suppliers alike. As international B2B buyers, understanding the nuances of these two restorative options can significantly impact your sourcing decisions and ultimately influence patient outcomes. Dental implants offer a durable, long-term solution for tooth replacement, while crowns and bridges provide effective alternatives that can restore functionality and aesthetics in a more conservative manner.

This guide delves deep into the intricacies of dental implants versus crowns and bridges, covering essential topics such as types of materials, manufacturing processes, quality control standards, and key suppliers in the global market. We will also explore the cost implications associated with each option, helping you navigate the financial landscape more effectively.

As buyers from diverse regions, including Africa, South America, the Middle East, and Europe, you face unique challenges and opportunities. This comprehensive resource is designed to empower you with actionable insights tailored to your specific market conditions. Whether you’re sourcing for a dental practice in Egypt or a dental supply company in Italy, this guide equips you with the knowledge necessary to make informed decisions that align with your business goals. Prepare to enhance your competitive edge in the global dental market by understanding the vital distinctions and applications of dental implants and crowns and bridges.

Understanding dental implants vs crowns and bridges Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dental Implants | Titanium posts surgically placed into the jawbone | Long-term tooth replacement, restorations | Pros: Durable, natural appearance; Cons: Higher initial cost, surgical procedure needed |

| Crowns | Caps placed over damaged teeth, typically made of porcelain or metal | Restoration of damaged teeth, aesthetics | Pros: Quick procedure, preserves tooth structure; Cons: Limited lifespan, may require replacement |

| Bridges | Fixed prosthetics that replace missing teeth using adjacent teeth for support | Tooth replacement, gap closures | Pros: Restores function and aesthetics; Cons: Requires alteration of adjacent teeth |

| All-on-4 Implants | A technique using four implants to support a full arch of teeth | Full arch restoration | Pros: Minimally invasive, quicker recovery; Cons: May not be suitable for all patients |

| Zirconia Crowns | Strong, aesthetic crowns made from zirconium oxide | Aesthetic restorations, long-term solutions | Pros: Excellent aesthetics, biocompatible; Cons: Higher cost than traditional crowns |

Dental Implants

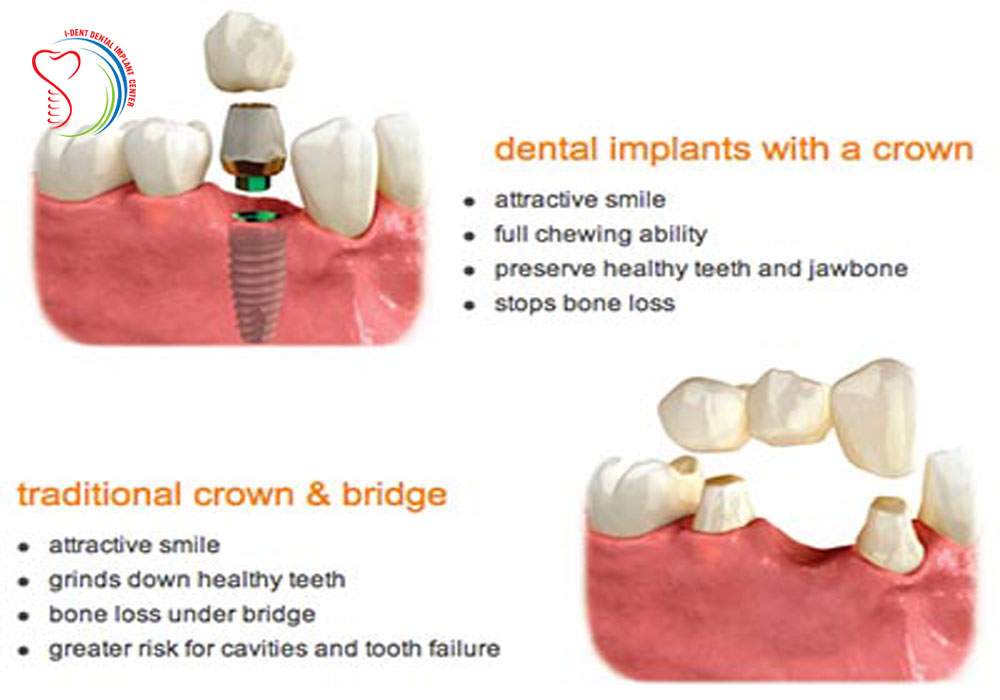

Dental implants are titanium posts surgically inserted into the jawbone to serve as artificial roots for missing teeth. They are suitable for patients seeking a long-term solution to tooth loss. B2B buyers should consider factors such as the implant’s material, compatibility with existing dental structures, and the required surgical expertise. The initial investment may be higher than other options, but their durability and natural appearance often justify the cost in long-term care.

Crowns

Crowns are caps placed over damaged or decayed teeth to restore their shape, size, and function. They can be made from various materials, including porcelain and metal. B2B buyers should assess the specific needs of their patient population when selecting crown materials, balancing aesthetics with durability. While crowns can be placed relatively quickly, their lifespan may be limited, necessitating future replacements, which can affect overall cost-effectiveness.

Bridges

Bridges are fixed prosthetics that replace one or more missing teeth by anchoring to adjacent teeth. They are ideal for patients who prefer a non-surgical option. B2B buyers must evaluate the impact of altering adjacent teeth, as this can lead to future complications. Bridges effectively restore both function and aesthetics but may require ongoing maintenance and eventual replacement, which should be factored into long-term care plans.

All-on-4 Implants

The All-on-4 technique involves placing four strategically positioned implants to support a full arch of prosthetic teeth. This approach minimizes the need for bone grafting and can significantly reduce recovery times. For B2B buyers, understanding the patient demographics that would benefit from this method is crucial. While it offers a quicker solution, not all patients may qualify, and the cost can be a barrier for some.

Zirconia Crowns

Zirconia crowns are made from zirconium oxide, offering exceptional strength and aesthetics. They are increasingly popular for long-term restorations due to their biocompatibility and ability to mimic natural tooth appearance. B2B buyers should consider the cost-effectiveness of zirconia crowns in comparison to traditional materials. Although they tend to be more expensive, their durability and aesthetic appeal can lead to greater patient satisfaction and potentially lower long-term costs.

Related Video: Types Of Dental Bridges

Key Industrial Applications of dental implants vs crowns and bridges

| Industry/Sector | Specific Application of Dental Implants vs Crowns and Bridges | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Use of dental implants for replacing missing teeth | Enhances patient satisfaction and retention | Quality of materials, supplier certifications, and lead times |

| Dental Laboratories | Fabrication of crowns and bridges for dental restoration | Streamlined workflow and reduced turnaround time | Material compatibility, technology used, and pricing |

| Healthcare Facilities | Integration of dental implants in oral surgery | Improved patient outcomes and reduced complications | Compliance with health regulations, training for staff, and equipment needs |

| Cosmetic Dentistry | Application of crowns for aesthetic enhancements | Increased service offerings and revenue streams | Aesthetic quality, durability, and supplier reliability |

| Insurance Providers | Coverage of dental implants and crowns in policy plans | Competitive advantage in attracting clients | Understanding of local regulations, cost structures, and reimbursement processes |

Dental Clinics

Dental clinics commonly utilize dental implants to replace missing teeth, providing a long-term solution for patients. This application not only restores functionality but also enhances aesthetics, leading to higher patient satisfaction and retention. For international B2B buyers, particularly in regions like Africa and South America, sourcing high-quality implants that comply with local regulations is crucial. Buyers should consider supplier certifications and the longevity of the materials used, as these factors directly impact patient outcomes and clinic reputation.

Dental Laboratories

In dental laboratories, crowns and bridges are fabricated to restore patients’ smiles and dental functionality. The use of advanced technologies such as CAD/CAM systems can significantly streamline workflows and reduce turnaround times for dental restorations. For B2B buyers, especially from Europe and the Middle East, it is essential to evaluate the compatibility of materials with existing technologies and the pricing structures of suppliers. This ensures that laboratories can maintain high standards while optimizing costs.

Healthcare Facilities

Healthcare facilities integrate dental implants into oral surgery practices to enhance patient outcomes. By offering implants, these facilities can address complex dental issues, reducing the likelihood of complications associated with traditional dentures. For international buyers, especially in regions with varying healthcare standards, sourcing compliant implants that meet local health regulations is vital. Additionally, training staff on the latest techniques and equipment is necessary to ensure successful implant procedures.

Cosmetic Dentistry

Cosmetic dentistry often employs crowns to enhance the aesthetic appeal of patients’ smiles. This application not only improves patient confidence but also allows practices to expand their service offerings, thus increasing revenue streams. B2B buyers in this sector must prioritize the aesthetic quality and durability of crowns when selecting suppliers. Reliability and a proven track record are also critical, particularly in competitive markets like Europe and the Middle East, where patient expectations are high.

Insurance Providers

Insurance providers increasingly include dental implants and crowns in their policy plans, recognizing the growing demand for advanced dental solutions. This inclusion offers a competitive advantage in attracting clients who seek comprehensive dental coverage. For buyers in this sector, understanding local regulations, cost structures, and reimbursement processes is essential. This knowledge enables them to design attractive insurance packages that meet market needs, particularly in diverse regions like Africa and South America, where dental care access can vary widely.

Related Video: Dental Crowns, Bridges, and Implants – Simply Explained

Strategic Material Selection Guide for dental implants vs crowns and bridges

When selecting materials for dental implants, crowns, and bridges, international B2B buyers must consider various factors that influence product performance, compliance, and market preferences. Below is an analysis of four common materials used in these dental applications: titanium, zirconia, porcelain-fused-to-metal (PFM), and composite resin.

Titanium

Key Properties:

Titanium is known for its excellent strength-to-weight ratio, high corrosion resistance, and biocompatibility. It can withstand the pressures of chewing and is stable in the oral environment, making it ideal for dental implants.

Pros & Cons:

Durability is one of titanium’s major advantages, as it can last for decades without degrading. However, the manufacturing process can be complex and costly, making it a higher investment upfront. For crowns and bridges, titanium is often used as a substructure due to its strength.

Impact on Application:

Titanium implants are compatible with various media, including bone tissue, which is crucial for osseointegration. However, its metallic color may not be aesthetically pleasing for crowns and bridges.

Considerations for International Buyers:

Buyers from regions like Africa, South America, and the Middle East should ensure that titanium products comply with international standards such as ASTM F136. In Europe, adherence to the Medical Device Regulation (MDR) is essential.

Zirconia

Key Properties:

Zirconia is a ceramic material that offers high strength and excellent aesthetic properties. It is also resistant to wear and has low thermal conductivity.

Pros & Cons:

Zirconia is highly durable and provides a natural tooth-like appearance, making it suitable for visible areas. However, it can be more brittle than titanium, which may limit its use in certain applications. The manufacturing process can also be more complex, leading to higher costs.

Impact on Application:

Zirconia is compatible with soft tissues and does not cause allergic reactions, making it a good choice for patients with sensitivities. Its aesthetic qualities make it ideal for crowns and bridges in the anterior region.

Considerations for International Buyers:

Buyers should verify that zirconia products meet ISO 6872 standards for dental ceramics. In regions like Europe, compliance with CE marking requirements is necessary.

Porcelain-Fused-to-Metal (PFM)

Key Properties:

PFM combines the strength of metal with the aesthetics of porcelain. The metal framework provides durability, while the porcelain offers a natural appearance.

Pros & Cons:

PFM crowns and bridges are versatile and can be used in various dental applications. However, they may be prone to chipping, and the metal substructure can cause a gray line at the gum line, which may be undesirable for some patients.

Impact on Application:

PFM is suitable for both anterior and posterior restorations, but the metal component may not be compatible with patients who have metal allergies.

Considerations for International Buyers:

Compliance with standards such as ISO 9693 for dental ceramics is crucial. Buyers should also consider regional preferences, as some markets may favor all-ceramic options for aesthetic reasons.

Composite Resin

Key Properties:

Composite resin materials are made from a mixture of plastic and glass particles. They offer good aesthetics and are easy to manipulate during the dental procedure.

Pros & Cons:

Composite resins are cost-effective and can be used for both crowns and bridges. However, they are less durable than other materials and may require more frequent replacements.

Impact on Application:

Composite resins are suitable for low-stress areas and are often used in anterior restorations. They bond well with tooth structure, enhancing retention.

Considerations for International Buyers:

It is essential to ensure that composite resins comply with standards such as ISO 4049. Buyers should also consider the regional acceptance of these materials, as some markets may prioritize longevity over aesthetics.

Summary Table

| Material | Typical Use Case for dental implants vs crowns and bridges | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Dental implants, substructure for crowns | High durability and biocompatibility | High manufacturing complexity and cost | High |

| Zirconia | Crowns and bridges, especially anterior | Excellent aesthetics and strength | Brittle under certain conditions | High |

| Porcelain-Fused-to-Metal (PFM) | Crowns and bridges for various applications | Versatile with good aesthetics | Prone to chipping and metal visibility | Medium |

| Composite Resin | Anterior crowns and bridges in low-stress areas | Cost-effective and easy to manipulate | Less durable, requires more frequent replacements | Low |

This guide provides actionable insights for international B2B buyers to make informed decisions about material selection for dental implants, crowns, and bridges, considering performance, compliance, and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for dental implants vs crowns and bridges

Understanding Manufacturing Processes

Manufacturing Processes for Dental Implants

-

Material Preparation

– Dental implants are primarily made from biocompatible materials such as titanium and zirconia. The manufacturing process begins with the selection of high-grade raw materials, which undergo rigorous testing to ensure they meet industry standards.

– Suppliers should provide certifications for raw materials, indicating compliance with standards such as ISO 13485, which pertains to medical devices. -

Forming

– The forming stage involves various techniques, including CNC (Computer Numerical Control) machining, which allows for precise shaping of the implant. Other methods include additive manufacturing (3D printing), particularly for complex geometries that enhance osseointegration.

– Buyers should inquire about the specific methods used by suppliers, as this can impact the quality and performance of the final product. -

Assembly

– For implants, assembly typically involves the integration of components such as abutments and screws. This stage must be carried out in a clean room environment to prevent contamination.

– Understanding the assembly process can help buyers gauge the reliability and longevity of the implants. -

Finishing

– The finishing process includes surface treatments like sandblasting, acid etching, and anodization, which improve biocompatibility and enhance the implant’s surface properties.

– B2B buyers should assess the finishing techniques employed by their suppliers to ensure they align with best practices for dental implants.

Manufacturing Processes for Crowns and Bridges

-

Material Preparation

– Crowns and bridges are often fabricated from materials like porcelain, metal alloys, or composite resins. The selection of these materials is crucial for durability and aesthetic results.

– Verify that suppliers have robust material sourcing policies and quality certifications. -

Forming

– The forming process for crowns and bridges typically involves CAD/CAM technology, which allows for precise digital design and milling of the restoration. This technology minimizes human error and enhances consistency.

– Buyers should ask about the software and machinery used, as this can directly affect the quality of the final product.

Illustrative Image (Source: Google Search)

- Assembly

– In the case of bridges, the assembly involves the connection of multiple crowns. This requires careful attention to the fit and alignment to ensure proper function.

– Understanding the assembly process can help buyers make informed decisions regarding the longevity and effectiveness of the restorations.

Illustrative Image (Source: Google Search)

- Finishing

– Similar to implants, finishing for crowns and bridges includes polishing and glazing, which are essential for aesthetics and functionality.

– Inquire about the finishing techniques used, as they can vary widely among suppliers and impact the final product’s performance.

Quality Assurance in Manufacturing

International Standards and Certifications

- B2B buyers should be well-acquainted with international standards such as ISO 9001 for quality management systems and ISO 13485 for medical devices. These certifications ensure that suppliers adhere to quality management principles, including strong customer focus and continuous improvement.

- Specific to Europe, CE marking is crucial as it indicates compliance with health, safety, and environmental protection standards.

Industry-Specific Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– This checkpoint involves the inspection of raw materials upon arrival at the manufacturing facility. It is crucial for ensuring that only high-quality materials are used in production.

– Buyers should require documentation that details the IQC processes in place at their suppliers. -

In-Process Quality Control (IPQC)

– IPQC is implemented during the manufacturing process to monitor and control quality at various stages. This can include checks on dimensions, surface finish, and other critical parameters.

– Ask suppliers for their IPQC protocols to ensure that they maintain high standards throughout production. -

Final Quality Control (FQC)

– The FQC phase is vital for ensuring that the finished products meet all specified requirements. This includes functional testing and visual inspections.

– Buyers should seek transparency from suppliers regarding their FQC processes and any testing methods used.

Common Testing Methods

- Common testing methods for dental implants include fatigue testing, pull-out testing, and biocompatibility testing. For crowns and bridges, aesthetic tests, wear resistance tests, and fit verification are typical.

- B2B buyers should require detailed reports on testing outcomes from their suppliers to ensure reliability and performance.

Verifying Supplier Quality Control

-

Audits

– Regular audits of suppliers are essential to verify compliance with quality standards. Buyers should consider conducting both announced and unannounced audits to gain a comprehensive understanding of the supplier’s operations.

– Engaging third-party auditors can provide an unbiased assessment of supplier quality. -

Reports

– Requesting quality control reports, including IQC, IPQC, and FQC data, can help buyers ascertain the reliability of their suppliers.

– Suppliers should be willing to provide these documents as part of their commitment to transparency. -

Third-Party Inspections

– Utilizing third-party inspection services can be beneficial, especially for international buyers who may not be able to conduct on-site audits.

– This step ensures that the products meet all necessary regulatory and quality standards before shipment.

Quality Control and Certification Nuances for International Buyers

- Buyers from Africa, South America, the Middle East, and Europe should be aware of regional regulations and standards that may impact their purchasing decisions. For example, the regulatory landscape in Europe is often more stringent compared to other regions.

- Understanding local certification requirements and ensuring that suppliers possess relevant accreditations is crucial for compliance and successful market entry.

By focusing on these key areas, international B2B buyers can make informed decisions when sourcing dental implants, crowns, and bridges, ensuring that they select suppliers who prioritize quality and compliance.

Related Video: Dental Bridge Procedure

Comprehensive Cost and Pricing Analysis for dental implants vs crowns and bridges Sourcing

When sourcing dental implants, crowns, and bridges, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This section delves into the various components influencing costs, the factors affecting pricing, and offers actionable tips for optimizing procurement strategies.

Cost Structure Breakdown

1. Cost Components

– Materials: The primary cost driver in dental implants, crowns, and bridges. Implants are typically made from titanium or zirconia, while crowns can be crafted from metal, porcelain, or resin. The choice of material significantly impacts the price.

– Labor: Skilled labor is essential for both manufacturing and fitting dental products. Regions with higher labor costs may see elevated pricing, which is particularly relevant for buyers in Europe compared to those in Africa and South America.

– Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can reduce these overheads, allowing suppliers to offer more competitive pricing.

– Tooling: Initial tooling costs for custom products can be substantial. Buyers should consider the implications of one-time tooling investments versus ongoing costs for standard products.

– Quality Control (QC): Ensuring product quality through rigorous QC processes incurs additional costs. Certifications (like ISO or CE) often add to the price but ensure compliance with international standards.

– Logistics: Transportation costs can vary significantly based on the origin of the products and destination. For buyers in Africa and the Middle East, understanding local logistics infrastructure is vital to avoid delays and unexpected costs.

– Margin: Suppliers typically add a margin to cover risks and ensure profitability. This margin can vary widely based on market conditions and competition.

Influencers on Pricing

2. Price Influencers

– Volume/MOQ: Purchasing in larger quantities can lead to significant discounts. Buyers should negotiate minimum order quantities (MOQs) to optimize pricing.

– Specifications/Customization: Custom products tend to be more expensive due to the additional time and resources required. Standardized products may offer better pricing but could compromise on specific clinical needs.

– Materials: The quality and origin of materials directly affect costs. For instance, high-grade titanium implants will typically cost more than lower-grade alternatives.

– Quality/Certifications: Products with higher quality assurance or certifications may command premium prices. Buyers must balance the cost with the assurance of quality.

– Supplier Factors: The supplier’s reputation, production capacity, and location can all influence pricing. Established suppliers may charge more but offer reliability and better service.

– Incoterms: Understanding the terms of shipping and delivery (Incoterms) is crucial. They dictate the responsibilities of buyers and sellers regarding transport costs and risks, impacting the total cost of ownership.

Buyer Tips for Cost Optimization

3. Strategic Procurement Insights

– Negotiation: Engage in thorough negotiations with suppliers to secure the best possible pricing. Leverage existing relationships and market research to strengthen your position.

– Cost-Efficiency: Assess the total cost of ownership, which includes not just the purchase price but also logistics, duties, and potential tariffs. This holistic view can reveal hidden costs.

– Pricing Nuances: Be aware of regional pricing variations. For instance, dental products sourced from Europe may be priced higher due to stringent regulations and higher labor costs compared to those sourced from South America or Africa.

– Supplier Diversification: Consider diversifying suppliers to mitigate risks associated with price fluctuations and supply chain disruptions. This can lead to better pricing options and reliability.

Disclaimer

Prices for dental implants, crowns, and bridges can vary significantly based on the factors discussed above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure informed purchasing decisions.

Spotlight on Potential dental implants vs crowns and bridges Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘dental implants vs crowns and bridges’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for dental implants vs crowns and bridges

Essential Technical Properties

When considering dental implants, crowns, and bridges, understanding the technical properties is crucial for making informed purchasing decisions. Here are some key specifications that B2B buyers should consider:

-

Material Grade

– Definition: The quality and composition of materials used, such as titanium for implants and porcelain or zirconia for crowns and bridges.

– Importance: Higher-grade materials typically offer better biocompatibility and durability, which can reduce the risk of implant failure and enhance patient satisfaction. Buyers should verify certifications and compliance with international standards, especially when sourcing from different regions. -

Tensile Strength

– Definition: The maximum amount of tensile (pulling) stress that a material can withstand before failure.

– Importance: Implants and restorations must endure significant forces from chewing and grinding. Products with higher tensile strength are less likely to fracture, which is critical for long-term success and patient safety. -

Surface Roughness

– Definition: A measure of the texture of the surface of an implant, typically quantified in micrometers (µm).

– Importance: Surface roughness affects osseointegration (the process by which the implant anchors to the bone). A rougher surface can enhance the biological bond, leading to a more stable implant. B2B buyers should evaluate surface treatments and their implications for performance. -

Corrosion Resistance

– Definition: The ability of a material to withstand degradation due to chemical reactions, particularly in a moist environment like the oral cavity.

– Importance: Implants made from corrosion-resistant materials will have a longer lifespan and reduced risk of complications. This property is particularly important in humid climates prevalent in many African and Middle Eastern markets. -

Compatibility with Imaging Techniques

– Definition: The ability of dental materials to be effectively visualized using imaging techniques such as X-rays or CT scans.

– Importance: Materials that do not interfere with imaging are critical for accurate diagnosis and treatment planning. Buyers should confirm that the products they purchase are compatible with common imaging modalities.

Common Trade Terminology

Understanding industry jargon is vital for effective communication and negotiation. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Buyers often work with OEMs to ensure they receive high-quality, reliable products that meet their specifications, particularly in the competitive dental market. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ can help buyers manage inventory costs and align purchasing strategies with demand. This is particularly important for businesses in regions with fluctuating market needs. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price bids from suppliers for specific products or services.

– Relevance: An RFQ is a critical tool for B2B buyers to obtain competitive pricing and evaluate different suppliers’ offerings. It helps streamline the procurement process. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international rules that clarify the responsibilities of buyers and sellers in international transactions.

– Relevance: Understanding Incoterms is crucial for international trade, as they define who is responsible for shipping, insurance, and tariffs. This knowledge helps in negotiating contracts and ensuring compliance with international shipping regulations. -

Lead Time

– Definition: The amount of time that passes from the initiation of a process until its completion, particularly in the context of manufacturing and delivery.

– Relevance: Knowing the lead time for dental products can help buyers plan their inventories and meet patient demand effectively. This is especially important in regions where supply chains can be unpredictable.

By grasping these essential properties and terms, B2B buyers can make better-informed decisions when sourcing dental implants, crowns, and bridges, ensuring quality and reliability in their offerings.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dental implants vs crowns and bridges Sector

Market Overview & Key Trends

The global dental implants vs. crowns and bridges market is witnessing transformative changes driven by technological advancements, evolving patient preferences, and increasing awareness of oral health. One of the primary drivers is the growing geriatric population, particularly in regions like Europe and the Middle East, where dental restoration needs are escalating. Additionally, the rise in disposable incomes in Africa and South America is making advanced dental procedures more accessible, thereby boosting demand for both dental implants and crowns and bridges.

Key sourcing trends include the increasing adoption of digital technologies such as CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) systems. These innovations streamline the production process, reducing lead times and enhancing customization capabilities for dental restorations. Moreover, international B2B buyers are increasingly prioritizing suppliers who demonstrate efficiency through digital integration, reducing costs while maintaining quality.

Another emerging trend is the shift towards minimally invasive procedures. This has led to a rise in the popularity of dental implants over traditional crowns and bridges, as they often provide longer-lasting solutions with less impact on adjacent teeth. For B2B buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with market demands.

Sustainability & Ethical Sourcing in B2B

The focus on sustainability and ethical sourcing is becoming paramount in the dental industry. Environmental impacts from the production of dental materials, particularly in the manufacturing of implants and crowns, have prompted stakeholders to seek eco-friendly alternatives. B2B buyers are increasingly looking for suppliers who can provide materials that are not only durable but also sourced responsibly.

Certifications such as ISO 14001 (Environmental Management) and materials that are biocompatible and recyclable are becoming essential criteria in supplier selection. Additionally, the use of ‘green’ materials, such as bioactive glass and sustainably sourced titanium for implants, is gaining traction. B2B buyers from Africa, South America, the Middle East, and Europe should prioritize partnerships with manufacturers committed to sustainable practices, as this not only enhances corporate responsibility but also appeals to a growing segment of environmentally conscious consumers.

Moreover, engaging with suppliers who have transparent supply chains can mitigate risks associated with unethical sourcing, ensuring compliance with international regulations and standards. This focus on sustainability can also lead to operational efficiencies, as waste reduction initiatives often result in cost savings.

Brief Evolution/History

The dental restoration sector has evolved significantly over the last few decades. Initially, dental crowns and bridges were the primary solutions for tooth loss, typically made from metal or porcelain. However, the introduction of dental implants in the 1980s revolutionized the field. Implants, which integrate with the jawbone, offered a more durable and aesthetically pleasing alternative. Over time, advancements in materials science and surgical techniques have improved the success rates and longevity of dental implants, making them a preferred choice among patients and dentists alike.

As the market continues to evolve, B2B buyers must stay informed about historical shifts and current innovations to make strategic decisions that cater to emerging trends and patient needs. This understanding is essential for optimizing product offerings and aligning with global market dynamics.

Related Video: Full Mouth Dental Implants: Everything You Need to Know and Cost

Frequently Asked Questions (FAQs) for B2B Buyers of dental implants vs crowns and bridges

-

What should I consider when vetting suppliers for dental implants, crowns, and bridges?

When vetting suppliers, prioritize their certifications, quality assurance processes, and industry reputation. Ensure they comply with international standards such as ISO 13485 for medical devices. Request samples to assess product quality and ask for references from other international buyers. Additionally, investigate their manufacturing capabilities and whether they can provide customization options to meet specific market needs in regions like Africa and South America. -

Can dental implants, crowns, and bridges be customized for my market?

Yes, many suppliers offer customization options to cater to different regional preferences and patient needs. This may include variations in material (e.g., zirconia vs. metal), color, or design. Discuss your requirements upfront with potential suppliers to understand their capabilities and lead times for customized products. It’s essential to ensure that any customizations comply with local regulations and standards. -

What are typical minimum order quantities (MOQs) and lead times for dental products?

MOQs can vary widely among suppliers, typically ranging from 50 to 500 units depending on the product and the supplier’s production capacity. Lead times for dental implants and restorations usually range from 4 to 12 weeks, depending on the complexity of the order and customization. Always clarify these details before placing an order to avoid supply chain disruptions, particularly when sourcing from different continents. -

What payment terms should I expect when sourcing dental implants and restorations internationally?

Payment terms can vary based on the supplier and your negotiation skills. Common practices include advance payments, letters of credit, or payment upon delivery. Ensure you understand the currency exchange implications and any transaction fees. Establishing a solid relationship with the supplier can also lead to more favorable payment terms over time, which is particularly beneficial for ongoing business relationships in regions like the Middle East and Europe. -

How can I ensure quality assurance and certifications for dental implants and restorations?

Request copies of relevant certifications, such as CE marking for European products or FDA approval for U.S. products. A robust quality assurance program should include regular audits, testing for biocompatibility, and adherence to international standards. Consider suppliers who participate in third-party quality assessments to validate their claims. Establishing a quality control process on your end can further mitigate risks. -

What logistics considerations should I keep in mind when sourcing dental products internationally?

Logistics play a critical role in international sourcing. Evaluate shipping methods, costs, and delivery times. Understand customs regulations and tariffs in your country to avoid unexpected fees. It’s advisable to work with suppliers who have experience in international shipping and can provide reliable tracking and insurance options. This is especially important when dealing with sensitive products like dental implants and crowns. -

How should I handle disputes with suppliers regarding product quality or delivery issues?

Having a clear contract that outlines quality expectations, delivery timelines, and dispute resolution procedures is vital. In the event of a dispute, maintain open communication with the supplier to resolve issues amicably. If necessary, escalate the matter through formal channels such as mediation or arbitration. Familiarize yourself with international trade laws that may apply to your transactions, particularly when dealing with suppliers from different regions. -

What are the best practices for maintaining a long-term relationship with suppliers?

Building a strong relationship with suppliers involves regular communication, timely payments, and constructive feedback. Schedule periodic reviews to discuss performance, address any concerns, and explore opportunities for collaboration. Attend industry events and trade shows to strengthen connections. Cultivating a partnership mentality can lead to better pricing, priority service, and more favorable terms over time, enhancing your supply chain resilience.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dental implants vs crowns and bridges

In conclusion, the strategic sourcing of dental implants, crowns, and bridges is vital for international B2B buyers looking to enhance their offerings in the dental market. Key takeaways include the importance of evaluating the long-term cost-effectiveness of implants versus crowns and bridges, as well as the growing demand for high-quality materials and innovative technologies. By understanding regional market dynamics, buyers can make informed decisions that align with local needs and preferences.

Value of Strategic Sourcing:

– Cost Management: Prioritizing products that provide durability and patient satisfaction can lead to reduced long-term costs.

– Supplier Relationships: Building strong relationships with reputable suppliers ensures access to the latest advancements and reliable support.

– Market Adaptation: Tailoring product offerings to regional demands, particularly in Africa, South America, the Middle East, and Europe, can drive competitive advantage.

As the dental market continues to evolve, embracing a strategic sourcing approach will empower B2B buyers to stay ahead of trends and meet the diverse needs of their clientele. Now is the time to evaluate your sourcing strategies and position your business for future growth in this dynamic industry.