Introduction: Navigating the Global Market for different type of dental implants

Dental implants have become a cornerstone in modern dentistry, providing innovative solutions for tooth replacement and significantly enhancing patient quality of life. As international B2B buyers in Africa, South America, the Middle East, and Europe navigate this evolving market, understanding the various types of dental implants is crucial. Each implant type—ranging from endosteal to subperiosteal and zygomatic—caters to specific clinical needs, making it essential for buyers to comprehend their unique characteristics, advantages, and limitations.

This guide offers a comprehensive overview of dental implants, detailing types, materials, manufacturing processes, quality control standards, and cost considerations. We delve into the latest additive manufacturing techniques and highlight key suppliers that can meet diverse market demands. By addressing common questions and concerns, this resource empowers B2B buyers to make informed sourcing decisions that align with their operational needs and local market conditions.

In a competitive landscape, leveraging this knowledge not only aids in selecting the right implant solutions but also enhances partnerships with suppliers, ensuring access to high-quality products that meet patient expectations. As you explore this guide, you will be better positioned to navigate the complexities of the global dental implant market, securing optimal outcomes for your business and the patients you serve.

Understanding different type of dental implants Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Endosteal Implants | Screw-like or cylinder-shaped, placed directly into the jawbone | General dentistry, tooth replacement | Pros: High stability, natural aesthetics; Cons: Requires sufficient jawbone density, more invasive. |

| Subperiosteal Implants | Positioned on top of the jawbone, suitable for limited height | Patients with insufficient jawbone height | Pros: Less invasive; Cons: Less stable, limited application. |

| Zygomatic Implants | Anchored in the zygomatic bone, used for severe bone atrophy | Advanced dental restoration, complex cases | Pros: Ideal for significant bone loss; Cons: Complex surgery, longer healing time. |

| Single Tooth Implants | Designed for replacing one missing tooth | Individual tooth replacement | Pros: Highly effective, aesthetic; Cons: Costly for single applications. |

| Implant-Supported Dentures | Dentures supported by multiple implants | Full arch replacements, edentulous patients | Pros: Enhanced stability, improved function; Cons: Requires multiple surgeries, higher cost. |

Endosteal Implants

Endosteal implants are the most prevalent type, providing a robust solution for tooth replacement. They are inserted directly into the jawbone and are ideal for patients with sufficient bone density. For B2B buyers, it’s crucial to consider the implant’s compatibility with various dental restoration techniques and ensure that the surgical procedures align with local regulations and standards. The high success rate and longevity of these implants make them a preferred choice in general dentistry.

Subperiosteal Implants

Subperiosteal implants are designed for patients with limited jawbone height who cannot undergo bone grafting. These implants are placed on top of the jawbone, providing a less invasive option. Buyers should evaluate the specific patient demographics within their market that may benefit from this alternative, especially in regions with a higher prevalence of bone loss. While they offer a quicker solution, their stability may not match that of endosteal implants, which is a critical consideration for long-term patient satisfaction.

Zygomatic Implants

Zygomatic implants are specialized for cases of severe bone atrophy in the upper jaw. They are anchored in the zygomatic bone, allowing for immediate loading in some cases. For B2B buyers, understanding the complexities involved in zygomatic implant procedures is vital, as these require specialized surgical skills and training. The ability to offer such advanced solutions can distinguish a dental practice in competitive markets, particularly in regions facing significant tooth loss challenges.

Single Tooth Implants

Single tooth implants are a straightforward solution for replacing individual missing teeth. Their design allows for aesthetic restoration while maintaining functionality. B2B buyers should focus on the materials used in manufacturing these implants, ensuring they meet international biocompatibility standards. Although effective, the cost associated with single tooth implants can be a barrier for some patients, making it essential for buyers to consider pricing strategies and financing options.

Implant-Supported Dentures

Implant-supported dentures provide a stable solution for patients requiring full arch replacements. These dentures are anchored by multiple implants, offering improved functionality over traditional dentures. For B2B buyers, the market potential for these products is significant, especially in areas with a high incidence of edentulism. However, the requirement for multiple surgeries and the associated costs necessitate clear communication of the benefits to patients, ensuring they understand the long-term value and enhanced quality of life these implants can provide.

Related Video: 3 Types of Dental Implants and Surface treatments explained!

Key Industrial Applications of different type of dental implants

| Industry/Sector | Specific Application of different type of dental implants | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Use of endosteal implants for single and multiple tooth replacements | Provides a long-term solution for patients with missing teeth, enhancing clinic reputation and patient satisfaction | Ensure implants meet regulatory standards and are sourced from reputable manufacturers with a proven track record. |

| Prosthodontics | Implementation of zygomatic implants for patients with severe bone atrophy | Enables effective rehabilitation of patients who would otherwise be ineligible for standard implants, expanding service offerings | Look for suppliers that offer custom solutions and training for complex procedures. |

| Dental Laboratories | Manufacturing of implant-supported bridges using advanced materials | Facilitates the creation of durable, aesthetic dental restorations, improving turnaround times and customer satisfaction | Consider suppliers that utilize cutting-edge manufacturing techniques like additive manufacturing for precision. |

| Orthodontic Practices | Integration of subperiosteal implants in orthodontic treatments | Provides stable anchorage points for orthodontic appliances, leading to better treatment outcomes | Assess the compatibility of implants with existing orthodontic technologies and ensure availability of specialized training. |

| Dental Supply Chains | Distribution of various implant types to clinics and labs | Ensures a consistent supply of high-quality dental implants, improving operational efficiency and client trust | Evaluate logistics capabilities, including import/export regulations and local market demand for specific implant types. |

Detailed Application Insights

Dental Clinics

In dental clinics, endosteal implants are predominantly used for replacing single or multiple missing teeth. These implants provide a durable and aesthetically pleasing solution, significantly enhancing patient satisfaction and clinic reputation. For international buyers, especially in regions like Africa and South America, it is crucial to source implants that comply with local regulations and standards. Establishing relationships with reputable manufacturers ensures reliability and support in case of complications.

Prosthodontics

Zygomatic implants are particularly beneficial in prosthodontics for patients suffering from severe bone atrophy in the upper jaw. By anchoring implants in the zygomatic bone, practitioners can offer restorative solutions to patients who would otherwise be ineligible for traditional implants. Buyers in the Middle East and Europe should seek suppliers who provide comprehensive training and support for these specialized procedures, ensuring successful outcomes and patient safety.

Dental Laboratories

In dental laboratories, the use of implant-supported bridges manufactured with advanced materials can significantly improve the quality and durability of dental restorations. This not only enhances the aesthetic appeal but also boosts turnaround times, leading to increased customer satisfaction. Buyers should focus on suppliers that employ state-of-the-art manufacturing techniques, such as additive manufacturing, to ensure precision and customization in their products.

Orthodontic Practices

Subperiosteal implants play a critical role in orthodontic practices by providing stable anchorage for orthodontic appliances. This stability leads to improved treatment outcomes and patient comfort. For buyers, especially in diverse markets like Turkey and Colombia, it is essential to assess the compatibility of these implants with existing orthodontic technologies and to ensure that adequate training is available for practitioners.

Dental Supply Chains

For dental supply chains, the distribution of various types of dental implants is vital for maintaining an efficient operation. Ensuring a consistent supply of high-quality implants builds trust with clinics and laboratories, ultimately enhancing client relationships. Buyers should evaluate the logistics capabilities of suppliers, considering factors such as import/export regulations and the specific demand for various implant types in their local markets.

Strategic Material Selection Guide for different type of dental implants

When selecting materials for dental implants, understanding the properties, advantages, disadvantages, and specific considerations for various regions is crucial for international B2B buyers. Here, we analyze four common materials used in dental implants: Titanium, Zirconia, Stainless Steel, and PEEK (Polyether Ether Ketone). Each material has unique characteristics that influence its application and suitability for different dental implant types.

Titanium

Key Properties:

Titanium is renowned for its high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. It withstands the physiological conditions of the oral environment, including exposure to saliva and oral bacteria.

Pros & Cons:

Titanium implants are durable and can last a lifetime with proper care. They are also relatively easy to manufacture and have a well-established history in dental applications. However, they can be more expensive than other materials, and the surgical procedure to place titanium implants can be complex, requiring skilled professionals.

Impact on Application:

Titanium is highly compatible with bone, promoting osseointegration, which is critical for the stability of dental implants. This makes it suitable for both endosteal and subperiosteal implants.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM F136 for titanium alloy implants. Additionally, understanding local regulations regarding the use of titanium in medical applications is essential, especially in regions like Africa and South America where regulatory frameworks may vary.

Zirconia

Key Properties:

Zirconia is a ceramic material known for its aesthetic appeal and biocompatibility. It has high strength and is resistant to wear and corrosion, making it suitable for dental applications.

Pros & Cons:

The primary advantage of zirconia implants is their tooth-like appearance, which enhances aesthetics, especially in the anterior region. However, they are more brittle than titanium, which may limit their application in load-bearing situations. Manufacturing zirconia implants can also be more complex, contributing to higher costs.

Impact on Application:

Zirconia is suitable for patients who are allergic to metals or prefer a metal-free option. Its aesthetic properties make it ideal for visible areas, but its brittleness can be a limitation in posterior applications.

Considerations for International Buyers:

Buyers should verify that zirconia implants meet standards such as ISO 6872 for dental ceramics. Additionally, understanding the market demand for aesthetic solutions in regions like Europe and the Middle East can guide purchasing decisions.

Stainless Steel

Key Properties:

Stainless steel is known for its strength, corrosion resistance, and affordability. It is often used in temporary implants or in pediatric dentistry due to its durability.

Pros & Cons:

Stainless steel implants are cost-effective and easy to manufacture, making them a popular choice for temporary solutions. However, they are not as biocompatible as titanium or zirconia and may lead to allergic reactions in some patients.

Impact on Application:

Stainless steel is typically used for temporary implants or in cases where aesthetics are not a primary concern. Its strength makes it suitable for short-term applications but not for long-term solutions.

Considerations for International Buyers:

Compliance with standards such as ASTM F138 for stainless steel implants is essential. Buyers should also consider the regional preferences for temporary versus permanent solutions, especially in developing markets.

PEEK (Polyether Ether Ketone)

Key Properties:

PEEK is a high-performance polymer known for its biocompatibility, chemical resistance, and mechanical strength. It is lightweight and can be used in various dental applications.

Pros & Cons:

PEEK offers excellent flexibility and comfort for patients, making it suitable for certain implant applications. However, it may not provide the same level of osseointegration as titanium, which can limit its long-term effectiveness.

Impact on Application:

PEEK is often used in conjunction with other materials to enhance patient comfort. Its aesthetic properties make it suitable for visible areas, but its lower integration with bone can be a drawback.

Considerations for International Buyers:

Buyers should ensure PEEK implants comply with ISO 10993 for biocompatibility. Understanding the acceptance of polymer-based implants in various regions, particularly in Europe, is crucial for market entry.

Summary Table

| Material | Typical Use Case for different type of dental implants | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Endosteal and subperiosteal implants | Excellent osseointegration | Higher cost and surgical complexity | High |

| Zirconia | Aesthetic anterior implants | Superior aesthetics | Brittle and complex manufacturing | High |

| Stainless Steel | Temporary implants | Cost-effective | Poor biocompatibility | Low |

| PEEK | Flexible implant applications | Lightweight and comfortable | Limited osseointegration | Medium |

This strategic material selection guide provides valuable insights for B2B buyers in the dental implant industry, helping them make informed decisions based on material properties, application suitability, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for different type of dental implants

The manufacturing processes and quality assurance measures for dental implants are crucial for ensuring product safety, efficacy, and reliability. For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding these processes can facilitate informed procurement decisions and foster partnerships with manufacturers that adhere to international standards.

Manufacturing Processes for Dental Implants

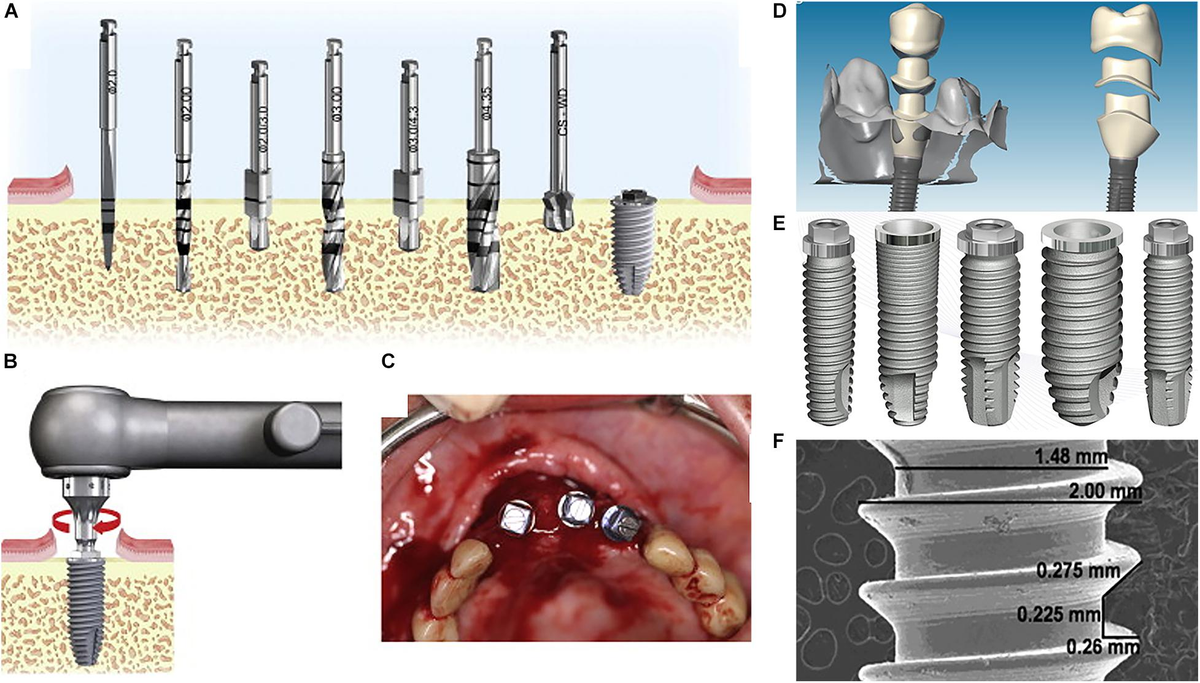

The manufacturing of dental implants typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical in ensuring the final product meets the necessary specifications and standards.

1. Material Preparation

Selection of Materials: The most common material used in dental implants is titanium due to its biocompatibility, strength, and resistance to corrosion. Alternatives, such as zirconia, are also gaining popularity for their aesthetic qualities.

Material Treatment: The selected materials undergo various treatments to enhance their properties. For titanium, processes such as anodization can increase surface roughness, which is beneficial for osseointegration.

2. Forming

Manufacturing Techniques: Several techniques are employed in the forming stage, including:

- CNC Machining: This method allows for precise shaping of the implant body from solid titanium blocks, ensuring high dimensional accuracy.

- Additive Manufacturing: Techniques such as 3D printing enable the creation of complex geometries that can optimize the implant’s integration with bone.

- Casting: While less common, some implants may still be produced using traditional casting methods.

Each method has its advantages and is selected based on the implant design, volume requirements, and cost considerations.

3. Assembly

In cases where dental implants include multiple components (such as abutments), assembly is a critical phase. This involves:

- Alignment and Fitting: Ensuring that all components fit together correctly to avoid complications during implantation.

- Sterilization: All assembled implants must undergo sterilization processes, commonly using autoclaving or ethylene oxide gas, to eliminate any microbial contamination.

4. Finishing

The final stage involves surface finishing to enhance aesthetic and functional properties. Techniques may include:

- Polishing: To achieve a smooth surface that reduces plaque accumulation.

- Coating: Applying biocompatible coatings can improve osseointegration rates and overall implant performance.

Quality Assurance in Dental Implant Manufacturing

Quality assurance is vital in the dental implant manufacturing process to ensure that products meet international and industry-specific standards. B2B buyers should be well-versed in the relevant quality standards and inspection processes.

Relevant International Standards

- ISO 9001: This standard pertains to quality management systems and ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

- ISO 13485: Specifically tailored for medical devices, this standard outlines requirements for a comprehensive quality management system.

- CE Marking: For products marketed in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For implants used in specific medical applications, adherence to API (American Petroleum Institute) standards may be required.

Illustrative Image (Source: Google Search)

QC Checkpoints

Quality control involves various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure compliance with specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing help identify defects early in the process.

- Final Quality Control (FQC): A thorough examination of the finished product ensures it meets all design and regulatory requirements.

Common Testing Methods

To validate the quality of dental implants, manufacturers employ a range of testing methods, including:

- Mechanical Testing: Assessing the strength and durability of the implant under simulated physiological conditions.

- Biocompatibility Testing: Ensuring that materials used do not elicit adverse reactions in the body.

- Surface Analysis: Evaluating the surface properties of implants to ensure optimal osseointegration.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control processes of suppliers is essential. Here are some actionable strategies:

- Audits: Conduct regular audits of supplier facilities to assess adherence to quality standards and processes.

- Quality Reports: Request detailed quality reports that outline testing results, compliance with standards, and any corrective actions taken.

- Third-Party Inspections: Engage independent third-party inspectors to validate the quality of the manufacturing process and final products.

Navigating QC Nuances for International Buyers

Understanding the nuances of quality control is crucial for B2B buyers operating across different regions:

- Regulatory Variations: Be aware of the specific regulatory requirements in your region, as they may differ significantly from those in the supplier’s country.

- Cultural and Language Barriers: Consider potential communication challenges when discussing quality standards and expectations with suppliers from different backgrounds.

- Supply Chain Risks: Evaluate the reliability of the supply chain, including transportation logistics and customs regulations, which can impact product quality upon arrival.

Conclusion

For B2B buyers in the dental implant industry, a comprehensive understanding of manufacturing processes and quality assurance practices is essential for ensuring the procurement of high-quality products. By focusing on international standards, implementing robust verification processes, and being aware of regional nuances, buyers can forge successful partnerships with manufacturers that prioritize quality and reliability. This knowledge not only aids in making informed purchasing decisions but also contributes to the overall success of dental practices and patient satisfaction.

Comprehensive Cost and Pricing Analysis for different type of dental implants Sourcing

Understanding the Cost Structure of Dental Implants

When sourcing dental implants, international B2B buyers must navigate a complex cost structure that includes various components. Understanding these elements can lead to more informed purchasing decisions and improved negotiations.

Cost Components:

– Materials: The primary material used for dental implants is titanium due to its biocompatibility and strength. The cost of titanium fluctuates based on market demand and availability. Other materials, such as zirconia, may also be considered, but they often come at a higher price point.

– Labor: The expertise required for manufacturing dental implants is significant. Skilled labor in implant design and production can contribute to higher costs, particularly in regions with elevated wage standards.

– Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Advanced manufacturing technologies, such as additive manufacturing, may increase overhead but can also enhance precision and reduce waste.

– Tooling: Custom tooling for specific implant designs can be expensive but is crucial for maintaining quality and achieving the desired specifications.

– Quality Control (QC): Rigorous QC processes are essential to ensure the implants meet health and safety standards. The costs associated with testing and certification can vary significantly based on regulatory requirements in different regions.

– Logistics: Shipping and handling costs are influenced by the distance between suppliers and buyers, as well as the chosen Incoterms. Understanding these terms can help buyers anticipate additional expenses.

– Margin: Suppliers typically add a markup to cover their costs and ensure profitability. This margin can vary widely based on the supplier’s position in the market and their reputation.

Price Influencers

Several factors can influence the pricing of dental implants, which international buyers should consider:

- Volume/MOQ (Minimum Order Quantity): Ordering in bulk can lead to significant discounts. Buyers should assess their needs and negotiate terms that reflect their purchasing power.

- Specifications/Customization: Customized implants or specific specifications often incur additional costs. Buyers should clearly define their requirements to avoid unexpected charges.

- Materials: The choice of materials directly impacts the cost. Titanium implants are generally less expensive than advanced ceramic options.

- Quality/Certifications: Implants with higher quality certifications or those that meet international standards may cost more but can ensure better performance and patient outcomes.

- Supplier Factors: The reliability and reputation of the supplier can affect pricing. Established suppliers may charge more due to their brand recognition and perceived quality assurance.

- Incoterms: Understanding the chosen Incoterms can help buyers calculate total costs, including shipping, tariffs, and insurance.

Buyer Tips for Cost-Efficiency

International B2B buyers can adopt several strategies to enhance cost-efficiency when sourcing dental implants:

- Negotiate: Engage in discussions with suppliers to negotiate better terms based on volume, payment timelines, and future contracts.

- Total Cost of Ownership (TCO): Consider not only the initial purchase price but also long-term costs associated with maintenance, patient satisfaction, and potential replacements.

- Research Local Regulations: Understanding the regulatory landscape in target markets like Africa, South America, the Middle East, and Europe can help avoid costly compliance issues.

- Evaluate Supplier Networks: Building relationships with multiple suppliers can provide leverage in negotiations and increase options for sourcing.

- Stay Updated on Material Costs: Regularly monitor market trends for materials to better predict and manage costs.

Disclaimer: The prices for dental implants can vary significantly based on the above factors and are subject to change. Buyers are encouraged to conduct thorough market research and request quotes tailored to their specific needs to ensure accurate budgeting.

Spotlight on Potential different type of dental implants Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘different type of dental implants’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for different type of dental implants

Key Technical Properties of Dental Implants

Understanding the essential technical specifications of dental implants is crucial for international B2B buyers, especially when sourcing products from different regions. Here are some of the critical properties to consider:

-

Material Grade

Dental implants are primarily made from titanium or titanium alloys due to their excellent biocompatibility and strength. The material grade affects the implant’s resistance to corrosion and its ability to integrate with the jawbone. Buyers should ensure that the implants meet international standards such as ISO 13485, which guarantees quality management systems in medical devices. -

Osseointegration Capability

This property refers to the ability of the implant to fuse with the jawbone. It is essential for ensuring the long-term success of the implant. Factors influencing osseointegration include surface texture and treatment methods. B2B buyers should inquire about the surface characteristics of implants, as these can significantly impact healing times and stability. -

Tolerance and Dimensions

Precision in the manufacturing process is critical for the fit and function of dental implants. Tolerance levels must be defined to ensure that components such as abutments and prosthetic restorations fit correctly. Buyers should check the manufacturer’s specifications for tolerance levels to avoid complications during installation. -

Load-Bearing Capacity

Dental implants must withstand masticatory forces without failure. The load-bearing capacity is influenced by the design (e.g., screw-type vs. cylinder-type) and the quality of the materials used. It is vital for buyers to assess whether the implant design is suitable for the intended application, particularly in high-stress areas. -

Surface Treatment Options

Surface treatments, such as sandblasting and acid etching, enhance the implant’s surface characteristics, promoting better osseointegration. Different treatments can be offered depending on the supplier, so buyers should evaluate which surface modifications might benefit their specific patient demographics or regional market needs.

Common Trade Terminology

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are key terms that international B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM produces parts or equipment that may be marketed by another manufacturer. In the dental implant industry, buyers may work directly with OEMs for custom implants or components, ensuring quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

This term indicates the smallest number of units a supplier is willing to sell. Understanding the MOQ is crucial for budgeting and inventory management, especially for businesses operating in regions with varying demand levels. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. Crafting a clear and detailed RFQ can help B2B buyers obtain accurate quotes and establish a basis for negotiation. -

Incoterms

International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in the shipping process. Understanding these terms is vital for international transactions, as they dictate who bears the risk and costs at various points in the delivery process. -

CE Marking

This certification indicates that a product meets EU safety, health, and environmental protection standards. For dental implants sold in Europe, CE marking is essential, and buyers should verify this certification to ensure compliance. -

Regulatory Compliance

This refers to adhering to local and international standards and regulations governing the manufacture and sale of medical devices. Buyers should ensure that their suppliers comply with relevant regulations in their target markets, such as the FDA in the U.S. or the Medical Device Regulation (MDR) in Europe.

Incorporating these technical properties and understanding trade terminology will empower B2B buyers to make informed decisions when sourcing dental implants internationally, ensuring quality and regulatory compliance.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the different type of dental implants Sector

Market Overview & Key Trends

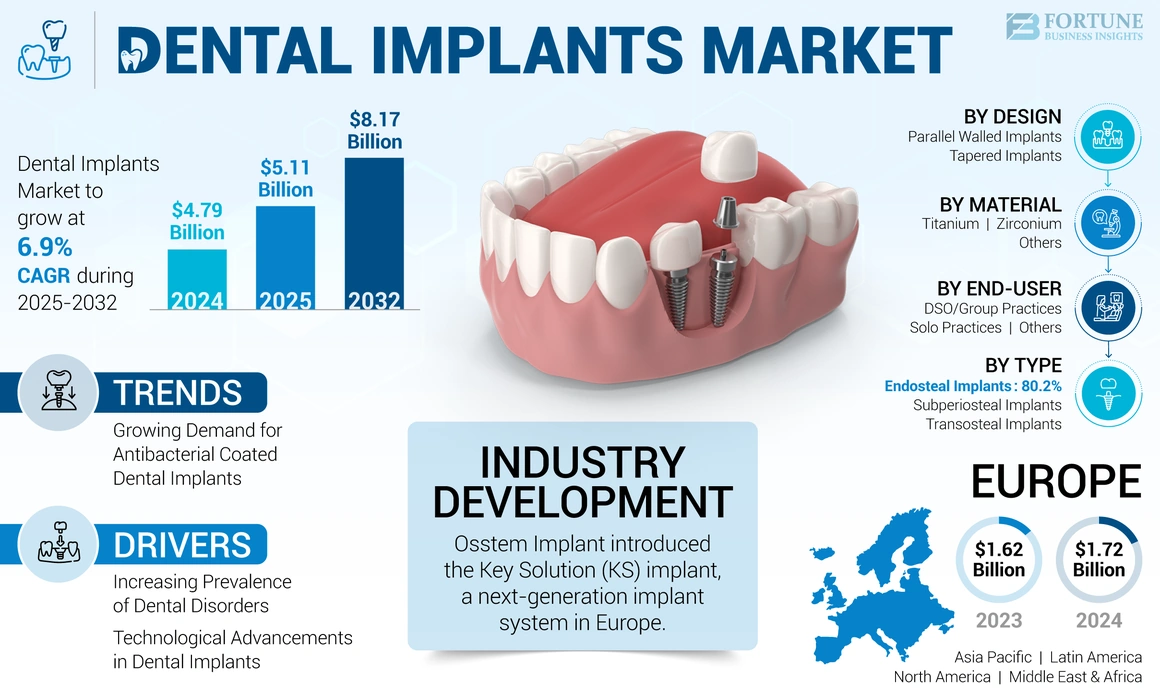

The dental implant market is experiencing robust growth, driven by increasing dental disorders, a rising geriatric population, and advancements in implant technologies. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding market dynamics is crucial. Notably, the demand for dental implants is expected to grow at a CAGR of approximately 7% from 2023 to 2030, influenced by the rising awareness of oral health and cosmetic dentistry.

Emerging trends include the adoption of digital dentistry technologies, such as 3D printing and computer-aided design (CAD), which streamline the manufacturing and customization of implants. This shift not only enhances the precision of implant placement but also reduces production costs. Additionally, the integration of biomaterials that promote osseointegration is becoming more prevalent, improving implant success rates.

Illustrative Image (Source: Google Search)

B2B buyers should also be mindful of regional preferences. For instance, in Europe, there’s a strong preference for high-quality, biocompatible titanium implants, while buyers in emerging markets may prioritize cost-effective solutions that do not compromise on quality. Understanding these nuances can help international buyers make informed sourcing decisions that align with local market expectations.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming increasingly significant in the dental implant sector, with a growing emphasis on ethical sourcing and environmentally friendly practices. The environmental impact of dental implants, particularly in terms of material extraction and manufacturing processes, necessitates a shift towards more sustainable practices.

B2B buyers should prioritize suppliers who utilize green certifications and materials, such as titanium sourced from responsible mines or biodegradable polymers for temporary implants. The use of additive manufacturing techniques not only reduces waste but also allows for the production of customized implants that meet specific patient needs.

Moreover, establishing ethical supply chains can enhance brand reputation and customer loyalty. Buyers are encouraged to engage with suppliers who demonstrate transparency in their sourcing processes and adhere to international labor standards. This commitment not only contributes to environmental sustainability but also aligns with the growing consumer preference for socially responsible products.

Brief Evolution/History

The history of dental implants dates back to ancient civilizations, but significant advancements have been made in the last few decades. Initially, dental implants were made from materials like gold and ivory, which often led to complications. The introduction of titanium in the 1960s marked a turning point, as its biocompatibility and strength facilitated better integration with bone.

Since then, the evolution of dental implants has been characterized by innovations in design and materials, including the development of mini implants for less invasive procedures and the use of advanced ceramics that enhance aesthetics. Today, the focus is on creating implants that not only function effectively but also promote sustainability, reflecting the industry’s response to both technological advancements and changing consumer expectations.

By staying informed about these historical developments, B2B buyers can appreciate the ongoing innovations that shape the market, allowing for better strategic sourcing decisions.

Related Video: Full Mouth Dental Implants: Everything You Need to Know and Cost

Frequently Asked Questions (FAQs) for B2B Buyers of different type of dental implants

-

What criteria should I use to vet suppliers of dental implants?

When vetting suppliers for dental implants, prioritize those with a proven track record and certifications such as ISO 13485, which indicates compliance with international quality management standards for medical devices. Check for their experience in the dental industry and solicit references from other B2B buyers. Assess their manufacturing processes, including materials used and adherence to safety regulations. Lastly, consider their customer service capabilities and responsiveness to inquiries, as ongoing support is crucial for a successful partnership. -

Can I customize dental implants to meet specific requirements?

Many suppliers offer customization options for dental implants, including variations in size, shape, and material. Discuss your specific needs with potential manufacturers to determine their capabilities in producing tailored solutions. Ensure that the supplier can provide prototypes or samples for evaluation. Customization might involve additional costs and lead times, so clarify these aspects during negotiations to avoid unexpected expenses. -

What are the typical minimum order quantities (MOQ) and lead times for dental implants?

Minimum order quantities (MOQ) can vary significantly by supplier, often ranging from 50 to 500 units. Smaller, niche manufacturers may offer lower MOQs but could charge higher prices. Lead times also differ based on the complexity of the order and the supplier’s production capacity, typically ranging from 4 to 12 weeks. Always discuss MOQs and lead times upfront to align with your inventory needs and patient demands. -

What payment terms should I expect when sourcing dental implants?

Payment terms can vary widely among suppliers, with options including upfront payment, partial payment upon order confirmation, or payment on delivery. Some suppliers may also offer credit terms for established buyers. It’s essential to negotiate favorable terms that align with your cash flow and procurement processes. Additionally, consider using secure payment methods that provide buyer protection, especially when dealing with international transactions. -

How do I ensure quality assurance and certification compliance?

Verify that your supplier adheres to relevant quality assurance protocols and possesses necessary certifications, such as CE marking in Europe or FDA approval in the USA. Request documentation of their quality control processes, including batch testing and inspection reports. Conducting periodic audits or quality checks can also help ensure ongoing compliance with industry standards. Establish clear expectations regarding quality benchmarks in your contracts to mitigate risks. -

What logistical considerations should I keep in mind when importing dental implants?

Importing dental implants requires careful attention to logistics, including understanding customs regulations in your country and the supplier’s country. Ensure that all shipments are properly documented to avoid delays at customs. Work with a reliable logistics partner experienced in handling medical devices to navigate shipping complexities. Additionally, factor in potential tariffs and duties that may impact your overall costs, and plan accordingly to maintain competitive pricing. -

How can I resolve disputes with suppliers?

Establish clear terms and conditions in your contracts to minimize the risk of disputes. In the event of a disagreement, start by addressing the issue directly with the supplier to seek an amicable resolution. If informal negotiations fail, consider mediation or arbitration as alternative dispute resolution methods before pursuing legal action. Maintaining open communication and a professional relationship can often prevent disputes from escalating. -

What are the best practices for ongoing supplier relationships in the dental implant industry?

Building strong relationships with suppliers is essential for long-term success. Regularly communicate your needs and feedback to foster collaboration. Schedule periodic reviews to assess performance, address any issues, and explore opportunities for further collaboration, such as new product development. Additionally, consider engaging in joint marketing efforts or training sessions to enhance product knowledge and ensure both parties are aligned in their goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for different type of dental implants

In conclusion, understanding the diverse types of dental implants is crucial for international B2B buyers looking to source high-quality dental solutions. Endosteal, subperiosteal, and zygomatic implants each serve specific needs, offering unique benefits and considerations that can influence purchasing decisions. For buyers in regions such as Africa, South America, the Middle East, and Europe, strategic sourcing is not just about obtaining products; it involves building partnerships with reputable suppliers that ensure quality, compliance with local regulations, and innovations in dental technology.

Key takeaways include the importance of evaluating the biocompatibility, design, and manufacturing methods of dental implants to ensure they meet the standards of the target market. As advancements in materials and manufacturing techniques, such as additive manufacturing, continue to evolve, staying informed will empower buyers to make strategic decisions that enhance their offerings.

Looking ahead, it is essential for B2B buyers to engage in continuous market research and establish robust supply chains that can adapt to changing demands. By prioritizing quality and innovation in sourcing, businesses can position themselves as leaders in the dental implant market, ultimately benefiting patients and enhancing their competitive edge.