Introduction: Navigating the Global Market for side effect of dental implants

In today’s rapidly evolving dental market, understanding the side effects of dental implants is crucial for B2B buyers aiming to make informed purchasing decisions. As the demand for dental implants increases across regions such as Africa, South America, the Middle East, and Europe, so does the necessity for comprehensive knowledge regarding potential complications and their implications on patient outcomes. This guide serves as an essential resource, offering insights into the various types of dental implants, the materials used, and the manufacturing and quality control processes that ensure safety and effectiveness.

Navigating the complexities of dental implants requires a thorough understanding of not only the products but also the associated risks. This guide will delve into the types of side effects, such as infection, implant failure, and bone loss, providing clarity on how these can impact patient satisfaction and long-term success. Additionally, we will explore the landscape of suppliers, cost considerations, and market trends, ensuring that B2B buyers are equipped with the knowledge to source the best products available.

By addressing frequently asked questions and offering actionable insights, this guide empowers international buyers to make strategic decisions that enhance their offerings and align with regulatory standards. Whether you are based in Brazil, Poland, or any other key market, understanding the side effects of dental implants is not just about risk management; it’s about building trust and ensuring the highest standards of care in dental practice.

Understanding side effect of dental implants Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Infection | Bacterial contamination at the implant site | Dental clinics, implant manufacturers | Pros: Early detection can lead to effective treatment. Cons: Can lead to implant failure if untreated. |

| Bone Loss | Resorption of jawbone surrounding the implant | Oral surgery centers, dental practices | Pros: Knowledge of risks can inform pre-surgery planning. Cons: May necessitate additional procedures. |

| Nerve Damage | Injury to surrounding nerves during implant placement | Oral and maxillofacial surgery facilities | Pros: Understanding nerve pathways can minimize risks. Cons: Can result in chronic pain or numbness. |

| Sinus Issues | Complications arising from upper jaw implants affecting sinuses | Dental specialists, ENT practices | Pros: Awareness can lead to better surgical techniques. Cons: Can require further medical intervention. |

| Implant Failure | Complete failure of the implant to integrate with bone | Dental product suppliers, surgical teams | Pros: Identifying risk factors can improve success rates. Cons: Replacement costs and patient dissatisfaction. |

Infection

Infection is a significant concern with dental implants, occurring when bacteria infiltrate the surgical site. This can arise due to poor oral hygiene, pre-existing conditions, or procedural errors. For B2B buyers, understanding the importance of sterilization and the implementation of preventive measures is crucial. Investing in high-quality surgical instruments and ensuring staff are trained in aseptic techniques can mitigate this risk, ultimately enhancing patient outcomes and reducing liability.

Bone Loss

Bone loss around dental implants can occur if the implant is not properly integrated into the jawbone. Factors contributing to this issue include inadequate bone density and improper placement. B2B buyers in the dental sector should consider the importance of pre-surgical assessments, including bone density scans, to determine the suitability of candidates for implants. Utilizing advanced imaging technologies and providing adequate bone grafting solutions can greatly improve the success rate of implants.

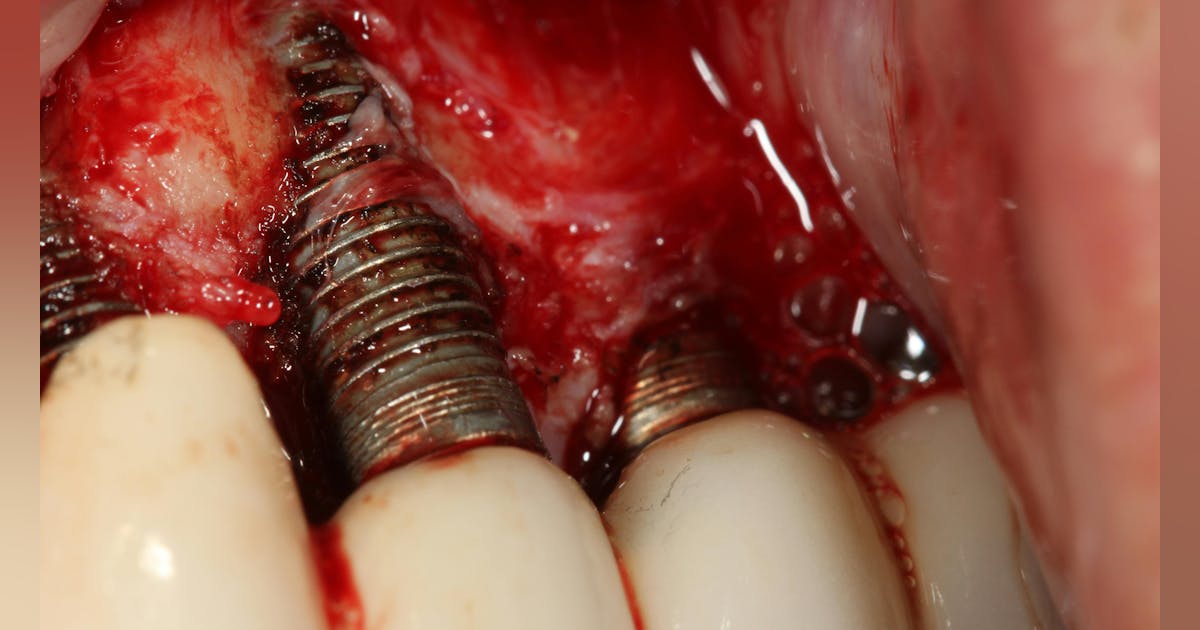

Illustrative Image (Source: Google Search)

Nerve Damage

Nerve damage can occur during the placement of dental implants, especially in the lower jaw where the mandibular nerve resides. This can lead to complications such as chronic pain or numbness. For B2B buyers, it’s essential to invest in training for dental professionals on the anatomy of the jaw and the use of imaging technologies to avoid nerve injury. Providing detailed guidelines and resources can enhance surgical precision, ultimately benefiting patient care and reducing the risk of litigation.

Sinus Issues

Implants placed in the upper jaw can sometimes encroach upon the sinus cavities, leading to complications such as sinusitis. This issue is particularly relevant for B2B buyers involved in dental and ENT practices. Awareness of the anatomical relationships in this area is critical, and investing in specialized training for implant placement can help prevent these complications. Additionally, offering sinus lift procedures as part of the implant process can enhance patient satisfaction and expand service offerings.

Implant Failure

Implant failure can occur due to various reasons, including infection, insufficient bone density, or mechanical issues with the implant itself. Understanding the factors that contribute to implant failure is essential for B2B buyers in the dental industry. This knowledge can guide purchasing decisions regarding implant materials and designs, as well as influence the selection of dental professionals. By focusing on high-quality products and thorough training, buyers can improve implant success rates, benefiting both practitioners and patients alike.

Related Video: 3 Types of Dental Implants and Surface treatments explained!

Key Industrial Applications of side effect of dental implants

| Industry/Sector | Specific Application of Side Effect of Dental Implants | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Managing complications like peri-implantitis | Enhanced patient care and retention | Quality of implant materials; availability of training on complication management |

| Medical Device Manufacturing | Development of innovative dental implant solutions | Competitive advantage through R&D and product differentiation | Compliance with international standards; sourcing of biocompatible materials |

| Insurance Providers | Evaluating risks associated with dental implants | Accurate risk assessment leading to better policy pricing | Data on implant failure rates; understanding of regional healthcare trends |

| Research Institutions | Conducting studies on the long-term effects of implants | Contribution to scientific knowledge and improved patient outcomes | Access to diverse patient demographics; collaboration with dental professionals |

| Regulatory Bodies | Setting guidelines for implant safety and efficacy | Improved public health outcomes and industry standards | Comprehensive data collection; international collaboration for standardization |

Dental Clinics

In dental clinics, understanding the side effects of dental implants, such as peri-implantitis, is crucial for effective patient management. This knowledge allows clinics to offer comprehensive care that includes preventive measures and treatment plans for complications. By addressing these issues, clinics can improve patient satisfaction and retention rates. International buyers in this sector should consider the quality of implant materials and ensure that staff are trained in the latest management techniques for complications.

Medical Device Manufacturing

For medical device manufacturers, the side effects of dental implants present opportunities for innovation. By researching and developing implants that minimize complications, these companies can differentiate their products in a competitive market. This focus on R&D not only enhances their product offerings but also addresses growing consumer demand for safer dental solutions. Buyers should prioritize compliance with international standards and seek biocompatible materials that align with best practices.

Insurance Providers

Insurance providers must evaluate the risks associated with dental implants to create accurate and competitive policy offerings. Understanding the side effects, such as implant failures or complications, allows insurers to develop risk profiles that inform policy pricing. This knowledge is essential for adapting to regional healthcare trends, particularly in diverse markets like Africa and South America. Buyers in this sector should focus on obtaining comprehensive data on implant failure rates and regional healthcare outcomes.

Research Institutions

Research institutions play a pivotal role in studying the long-term effects of dental implants, including their side effects. By conducting thorough investigations, these institutions contribute valuable insights that can lead to improved patient outcomes and advancements in dental technology. Collaborating with dental professionals and accessing diverse patient demographics can enhance the quality of research. International buyers should seek partnerships that facilitate data sharing and promote cross-border research initiatives.

Regulatory Bodies

Regulatory bodies are essential in setting guidelines and standards for the safety and efficacy of dental implants. By understanding the side effects associated with these devices, they can establish comprehensive regulations that protect public health and ensure industry accountability. International collaboration is vital for creating uniform standards that address the unique challenges faced in different regions. Buyers in this sector should focus on comprehensive data collection and stakeholder engagement to enhance regulatory frameworks.

Related Video: DENTAL IMPLANTS : TYPES, SURFACE TREATMENTS, why TITANIUM is used for making implants?

Strategic Material Selection Guide for side effect of dental implants

When selecting materials for dental implants, particularly in relation to their side effects, it is crucial to consider the properties, advantages, and limitations of each material. Below is an analysis of four common materials used in dental implants, focusing on their performance, application impact, and considerations for international B2B buyers.

Titanium

Key Properties: Titanium is renowned for its excellent biocompatibility, corrosion resistance, and strength-to-weight ratio. It can withstand the physiological conditions of the oral cavity, including temperature fluctuations and pressure from chewing.

Pros & Cons: The durability of titanium implants is a significant advantage, as they can last for many years without degradation. However, they are relatively expensive compared to other materials, and the manufacturing process can be complex, requiring specialized techniques. Titanium implants are highly suitable for osseointegration, which is critical for long-term stability.

Impact on Application: Titanium is compatible with various media, including saliva and blood, making it an ideal choice for dental applications. Its ability to integrate with bone enhances the success rate of implants.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of the varying standards for titanium implants, such as ASTM F136 and ISO 5832-2. Ensuring compliance with these standards is essential for product acceptance in local markets.

Zirconia

Key Properties: Zirconia is a ceramic material known for its aesthetic appeal and strength. It offers high fracture toughness and is resistant to wear and corrosion.

Pros & Cons: One of the main advantages of zirconia is its tooth-like appearance, making it an excellent choice for visible implants. However, it is more brittle than titanium, which can lead to fracture under high stress. The cost of zirconia is generally higher due to its manufacturing complexity.

Impact on Application: Zirconia is particularly suitable for patients with metal allergies, as it is a metal-free option. Its compatibility with oral tissues is favorable, but care must be taken in high-stress applications.

Considerations for International Buyers: Compliance with standards such as ISO 6872 is crucial for zirconia implants. Buyers in Europe, particularly in Poland, may prefer zirconia due to its aesthetic properties, aligning with local market trends.

Polyether Ether Ketone (PEEK)

Key Properties: PEEK is a high-performance polymer known for its excellent mechanical properties and biocompatibility. It exhibits good resistance to chemicals and can withstand high temperatures.

Pros & Cons: PEEK is lightweight and has a lower cost compared to metals, making it an attractive option for dental implants. However, its lower strength compared to titanium can be a limitation in load-bearing applications. The manufacturing process can also be complex, requiring advanced techniques.

Impact on Application: PEEK is compatible with various biological environments, making it suitable for dental applications. Its flexibility can be advantageous in certain cases, but it may not provide the same level of osseointegration as titanium.

Considerations for International Buyers: Buyers should ensure that PEEK implants comply with relevant standards, such as ASTM F2026. In regions like the Middle East, where regulatory frameworks are evolving, understanding local compliance requirements is essential.

Cobalt-Chromium Alloys

Key Properties: Cobalt-chromium alloys are known for their strength, wear resistance, and corrosion resistance. They are often used in dental applications due to their durability.

Pros & Cons: The primary advantage of cobalt-chromium alloys is their high strength, making them suitable for load-bearing implants. However, they can be more expensive than titanium and may pose challenges in terms of biocompatibility for some patients.

Impact on Application: These alloys are compatible with various biological fluids, but their potential for causing allergic reactions in sensitive individuals should be considered.

Considerations for International Buyers: Compliance with standards such as ISO 22674 is critical. Buyers from South America should be aware of the local market’s preferences for materials, as cobalt-chromium may not be as widely accepted as titanium.

Summary Table

| Material | Typical Use Case for side effect of dental implants | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Standard dental implants requiring osseointegration | Excellent durability and biocompatibility | Higher cost and complex manufacturing | High |

| Zirconia | Aesthetic dental implants for visible areas | Tooth-like appearance | Brittle under stress | High |

| Polyether Ether Ketone | Flexible dental applications | Lightweight and lower cost | Lower strength than metals | Medium |

| Cobalt-Chromium Alloys | Load-bearing dental implants | High strength and wear resistance | Potential biocompatibility issues | High |

This strategic material selection guide provides essential insights for B2B buyers in the dental implant market, facilitating informed decisions based on material properties, application impacts, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for side effect of dental implants

Understanding Manufacturing Processes for Dental Implants

When considering the side effects of dental implants, it is crucial for B2B buyers to have a comprehensive understanding of the manufacturing processes involved. The quality of dental implants directly influences their performance and the likelihood of complications. Here are the main stages in the manufacturing process, alongside key techniques utilized.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Raw Materials: Titanium and zirconia are the most commonly used materials for dental implants due to their biocompatibility and strength. Buyers should verify the origin and quality of these materials, as impurities can lead to adverse reactions.

– Material Treatment: Processes such as anodization enhance the surface properties of titanium, promoting osseointegration. Ensure that suppliers provide detailed documentation on the treatment methods used. -

Forming

– Machining: This involves cutting and shaping the raw materials into the desired implant form. Computer Numerical Control (CNC) machining is often employed for precision.

– Additive Manufacturing: Increasingly used, this technique allows for the creation of complex geometries that enhance implant performance. B2B buyers should assess whether suppliers utilize advanced manufacturing technologies. -

Assembly

– Component Integration: This stage involves assembling various components, such as the implant body and abutment. Quality of assembly is critical to avoid misalignment, which can lead to complications.

– Sterilization Procedures: Dental implants must be sterilized to eliminate any microbial contamination before they reach the market. Verification of sterilization methods (e.g., autoclaving) is essential. -

Finishing

– Surface Treatment: Techniques such as sandblasting and acid etching are employed to enhance the surface roughness of implants, promoting better integration with bone.

– Quality Checkpoints: Before final packaging, implants undergo several inspections to ensure they meet specified standards.

Quality Assurance in Dental Implant Manufacturing

Quality assurance is paramount in the manufacturing of dental implants. B2B buyers should be familiar with relevant international standards and specific industry certifications to ensure product safety and efficacy.

International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). Suppliers should be certified to ISO 9001 to ensure consistent quality in their manufacturing processes.

- ISO 13485: Specifically for medical devices, this standard focuses on QMS requirements for organizations involved in the design, production, and distribution of medical devices, including dental implants.

Industry-Specific Certifications

- CE Marking: For suppliers operating in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards. Buyers should ensure that the products they source are CE marked.

- FDA Approval: In the U.S., dental implants must be approved by the FDA, which involves rigorous testing for safety and efficacy. Buyers should inquire about FDA-approved products if sourcing from suppliers that cater to the U.S. market.

Quality Control Checkpoints

Quality control (QC) is a multi-faceted process that includes several checkpoints throughout the manufacturing cycle:

-

Incoming Quality Control (IQC)

– This initial stage involves inspecting raw materials and components upon arrival at the manufacturing facility. It ensures that only quality materials enter the production process. -

In-Process Quality Control (IPQC)

– During manufacturing, random samples are tested to ensure that production processes remain within specified limits. This may include dimensional checks and surface quality assessments. -

Final Quality Control (FQC)

– Before products are packaged and shipped, a thorough inspection is conducted. This includes functional testing, sterilization verification, and packaging integrity checks.

Common Testing Methods

- Mechanical Testing: Assessing tensile strength, fatigue resistance, and wear properties of the implants.

- Biocompatibility Testing: Evaluating how the implant interacts with human tissue to prevent adverse reactions.

- Sterility Testing: Ensuring that the sterilization process effectively eliminates all viable microorganisms.

Verifying Supplier Quality Control

B2B buyers should adopt a proactive approach to verify the quality control practices of their suppliers:

- Conduct Audits: Regularly auditing suppliers can help ensure compliance with quality standards. This includes reviewing their QMS and manufacturing processes.

- Request Documentation: Suppliers should provide detailed reports on their quality assurance processes, including certifications and testing results.

- Engage Third-Party Inspectors: Utilizing independent third-party inspectors can offer an unbiased assessment of the supplier’s quality practices.

Navigating QC/CERT Nuances for International Buyers

For B2B buyers from Africa, South America, the Middle East, and Europe, understanding the nuances of quality certifications can help in making informed purchasing decisions:

- Regional Compliance: Different regions may have varying regulatory requirements. Buyers should familiarize themselves with local regulations to ensure compliance.

- Language and Documentation: Ensure that all quality documentation is available in a language that is easily understood, as misinterpretations can lead to compliance issues.

- Building Relationships: Establishing strong relationships with suppliers can facilitate better communication regarding quality standards and expectations, ultimately leading to improved product quality.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance protocols for dental implants is essential for B2B buyers. By leveraging this knowledge, buyers can make informed decisions, minimize risks associated with side effects, and ensure they source high-quality products that meet international standards.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for side effect of dental implants Sourcing

When sourcing dental implants, understanding the comprehensive cost structure and pricing analysis related to their side effects is crucial for international B2B buyers. This knowledge enables buyers to make informed decisions, especially when navigating the complexities of different markets such as Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary materials used in dental implants—such as titanium or zirconia—vary significantly in price based on quality and source. Premium materials that offer better biocompatibility and durability can increase costs but may reduce side effects in the long term.

-

Labor: Labor costs for manufacturing dental implants differ across regions. In countries with higher labor costs, such as those in Western Europe, the overall pricing may be elevated. Conversely, sourcing from regions with lower labor costs can provide savings but may impact quality and compliance with international standards.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and administrative costs that are typically allocated per unit produced. Efficient manufacturing processes can help mitigate overhead costs, which is particularly important for B2B buyers looking to maximize margins.

-

Tooling: The initial investment in tooling for custom or specialized implants can be significant. Buyers should consider whether the supplier has the capability to handle such tooling and how that affects the pricing structure.

-

Quality Control (QC): Rigorous QC processes are essential, especially given the potential side effects of implants. Investing in quality assurance can prevent costly recalls and enhance product reliability, thus influencing overall pricing.

-

Logistics: Transportation and handling costs are critical, especially for international shipments. Factors such as distance, shipping method, and customs duties can affect the total cost. Efficient logistics can also minimize delays, which is essential for maintaining supply chains.

-

Margin: Suppliers typically include a margin that reflects their operational risks and profit goals. Understanding the competitive landscape can help buyers negotiate better margins.

Price Influencers

-

Volume/MOQ: Larger orders generally lead to lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to negotiate minimum order quantities (MOQs) that align with their demand forecasts.

-

Specifications/Customization: Custom implants tailored to specific patient needs can significantly influence pricing. Buyers should clearly communicate their requirements to avoid unexpected costs.

-

Materials and Quality Certifications: High-quality materials often come with certifications that ensure compliance with international standards. Buyers should verify these certifications to assess the reliability of the implants.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may command higher prices but also offer better service and quality assurance.

-

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) can help buyers determine their responsibilities regarding shipping, insurance, and tariffs, which directly affect overall costs.

Buyer Tips

-

Negotiation: Engage in proactive negotiations with suppliers. Highlighting your purchasing power and exploring long-term contracts can lead to better pricing and terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not only the purchase price but also maintenance, warranty, and potential side effect management costs.

-

Pricing Nuances: Be aware of regional pricing variations. For example, imports into Africa may incur higher tariffs compared to intra-European transactions. Understanding these nuances can lead to significant cost savings.

-

Market Research: Conduct thorough market research to identify potential suppliers and compare pricing structures. Utilize local trade shows and industry associations to gather insights.

Disclaimer

The prices discussed in this analysis are indicative and may fluctuate based on market conditions, supplier negotiations, and regulatory changes. It is advisable to conduct a detailed analysis tailored to specific sourcing needs and market dynamics.

Essential Technical Properties and Trade Terminology for side effect of dental implants

Key Technical Properties of Dental Implants

Understanding the essential technical properties of dental implants is crucial for B2B buyers, especially those involved in procurement for dental practices or manufacturing. Here are some critical specifications that you should consider:

-

Material Grade

Dental implants are typically made from titanium or titanium alloys due to their biocompatibility and strength. The material grade indicates the quality and purity of the titanium used. Higher-grade materials (e.g., Grade 4 titanium) offer better mechanical properties and corrosion resistance, which are vital for long-term success in dental applications. For buyers, selecting high-grade materials can reduce the risk of implant failure and improve patient satisfaction. -

Surface Treatment

The surface of dental implants can be treated to enhance osseointegration—the process by which the implant bonds with the bone. Common treatments include sandblasting, acid etching, or the application of bioactive coatings. Understanding these treatments helps buyers ensure that the implants they procure will have optimal performance in various clinical scenarios, especially in regions with different bone quality. -

Tolerance

Tolerance refers to the permissible limits of variation in the dimensions of the implant. High precision in manufacturing tolerances ensures that the implants fit properly with abutments and prosthetics. Buyers should prioritize manufacturers that adhere to strict tolerance standards, as this can significantly affect the ease of installation and the overall success of dental procedures. -

Load-Bearing Capacity

This property indicates how much stress an implant can withstand during chewing and other functions. It is crucial for ensuring the longevity and functionality of the implant. Buyers should inquire about the load-bearing specifications of implants to ensure they meet the demands of various patient profiles, particularly in markets with diverse demographic needs. -

Corrosion Resistance

Corrosion can lead to implant failure over time. Implants must be resistant to the corrosive effects of bodily fluids. Understanding the corrosion resistance ratings of different materials can help buyers avoid costly replacements and ensure patient safety.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation in the dental implant market. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are then sold under another company’s brand. For B2B buyers, sourcing from reputable OEMs can ensure product quality and reliability, which is essential for maintaining brand reputation in the dental field. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is vital for buyers to manage inventory and cash flow effectively. Buyers should negotiate MOQs that align with their purchasing capabilities and market demand. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and availability for specific products. Crafting a detailed RFQ can lead to better pricing and terms, making it a critical tool for B2B buyers in the dental implant market. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and rights in international transactions, which is crucial for smooth importation of dental implants. -

CE Marking

In Europe, CE marking indicates that a product meets EU safety, health, and environmental protection standards. For B2B buyers in Europe, ensuring that dental implants have CE marking is critical for regulatory compliance and market access.

By understanding these technical properties and trade terminologies, international B2B buyers can make informed decisions, ensuring that they procure high-quality dental implants that meet both clinical and regulatory requirements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the side effect of dental implants Sector

Market Overview & Key Trends

The global dental implants market is witnessing significant growth, driven by the rising prevalence of dental diseases, an aging population, and increasing consumer awareness regarding oral health. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding market dynamics is crucial. Notably, technological advancements in implant materials and manufacturing processes are reshaping the landscape. Innovations such as 3D printing and computer-aided design (CAD) are reducing production costs and lead times, making it easier for international buyers to source high-quality implants.

Furthermore, emerging trends such as digital dentistry are gaining traction, with tools like intraoral scanners enhancing the accuracy and efficiency of dental procedures. This shift not only improves patient outcomes but also influences sourcing decisions. B2B buyers should consider suppliers who are early adopters of these technologies, as they are likely to offer competitive pricing and superior product quality.

Another notable trend is the increasing focus on biocompatibility and personalized dental solutions. International buyers should prioritize partnerships with manufacturers that invest in research and development to create implants that cater to diverse patient needs. Keeping an eye on regional regulations is also essential, as compliance can impact sourcing strategies and product availability.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical consideration in the dental implants sector, with increasing emphasis on environmental impact and the ethical sourcing of materials. B2B buyers are now more aware of their suppliers’ sustainability practices, making it essential to choose partners who prioritize eco-friendly production methods and materials. This includes the use of recycled metals and biocompatible polymers that minimize environmental footprints.

Illustrative Image (Source: Google Search)

Moreover, the importance of ethical supply chains cannot be overstated. Buyers should seek out suppliers that adhere to fair labor practices and transparent sourcing of raw materials. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability. By aligning with suppliers who prioritize ethical practices, buyers can enhance their brand reputation and meet the growing consumer demand for responsible products.

Incorporating sustainable practices not only addresses ethical concerns but also presents opportunities for cost savings in the long run. By investing in energy-efficient manufacturing processes and waste reduction strategies, companies can reduce operational costs while contributing positively to the environment.

Brief Evolution/History

The evolution of dental implants dates back to ancient civilizations, with the first recorded use of tooth replacements made from seashells and ivory. The modern dental implant era began in the 1960s with the discovery of osseointegration by Dr. Per-Ingvar Brånemark, which paved the way for titanium implants. Over the decades, advancements in materials science, digital technology, and surgical techniques have transformed the sector, leading to more effective and reliable implant solutions.

This historical context is vital for B2B buyers as it highlights the continuous innovation in the field. Understanding the evolution of dental implants can inform sourcing decisions, particularly when considering the latest technologies and materials that enhance patient outcomes and operational efficiencies. By aligning with suppliers who are at the forefront of these developments, buyers can ensure they are offering the best solutions in a competitive market.

Related Video: Dental Implants Cost Guide – 9 Factors Influencing What You Pay

Frequently Asked Questions (FAQs) for B2B Buyers of side effect of dental implants

-

What are the common side effects of dental implants that B2B buyers should be aware of?

B2B buyers should be informed that common side effects of dental implants include pain at the implant site, swelling, bruising, and potential infection. Long-term complications may involve implant failure, nerve damage, or sinus problems, particularly with upper jaw placements. Understanding these risks allows buyers to better assess product quality and supplier reliability, ensuring they offer clients safe and effective solutions. -

How can I vet suppliers for dental implants to ensure quality and minimize side effects?

When vetting suppliers, prioritize those with ISO certification or equivalent quality management systems. Request documentation on their manufacturing processes, materials used, and clinical studies demonstrating product efficacy. Additionally, consider suppliers who provide comprehensive warranties and after-sales support, as this can be indicative of their commitment to quality and customer satisfaction. -

Can dental implants be customized to address specific patient needs?

Yes, many suppliers offer customization options for dental implants, including size, material, and surface treatment tailored to individual patient anatomy. This customization can significantly reduce the risk of complications and improve patient outcomes. When sourcing implants, inquire about the supplier’s capabilities in customization and their process for ensuring the implants meet specific clinical requirements. -

What are typical minimum order quantities (MOQs) and lead times for dental implants?

MOQs for dental implants can vary widely based on the supplier and the type of implants being ordered. Typically, they range from 10 to 100 units. Lead times may also differ, generally taking 4-8 weeks for standard orders. B2B buyers should discuss these terms upfront to ensure they align with their inventory and patient demand, and to avoid potential delays in treatment. -

What payment terms are common when sourcing dental implants internationally?

Payment terms can vary significantly by supplier and region. Common terms include 30% upfront and 70% upon delivery, or payment in full prior to shipment. It’s essential to establish clear payment terms during negotiations, considering factors like currency fluctuations and international transaction fees. Buyers should also explore options for letters of credit or escrow services to mitigate financial risk. -

What quality assurance certifications should I look for in dental implant suppliers?

B2B buyers should seek suppliers with internationally recognized certifications such as ISO 13485 for medical devices, CE marking for the European market, and FDA approval for the U.S. These certifications ensure that the implants meet stringent safety and efficacy standards. Additionally, reviewing the supplier’s quality control processes and post-market surveillance practices can provide further assurance of product reliability. -

How can I manage logistics and shipping for dental implants?

Efficient logistics management is crucial when sourcing dental implants. Buyers should work with suppliers who have established shipping protocols, including temperature control for sensitive products. It’s advisable to partner with logistics providers experienced in medical device transportation. Discuss incoterms to clarify responsibilities for shipping costs, customs duties, and insurance to avoid unexpected expenses or delays. -

What should I do if I encounter a dispute with a dental implant supplier?

In the event of a dispute, first attempt to resolve the issue directly with the supplier through clear communication. Document all correspondence and agreements. If resolution fails, consider mediation or arbitration as stipulated in the contract. Additionally, familiarize yourself with international trade laws and dispute resolution mechanisms that can assist in resolving conflicts effectively and preserving business relationships.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for side effect of dental implants

In conclusion, the strategic sourcing of dental implants necessitates a thorough understanding of the potential side effects and their implications for patient care and business operations. International B2B buyers must prioritize sourcing from suppliers who demonstrate transparency in their product specifications and provide comprehensive support for managing side effects. This includes investing in educational resources and training for dental professionals to ensure proper patient management and satisfaction.

Key takeaways for buyers include:

- Supplier Selection: Choose suppliers that offer robust clinical data and a history of reliability in managing side effects.

- Risk Management: Implement effective risk assessment strategies to mitigate potential complications associated with dental implants.

- Collaboration: Foster partnerships with manufacturers for ongoing education and support, enhancing the overall quality of care.

Looking forward, the dental implant market is poised for growth, driven by technological advancements and increased demand for cosmetic procedures. Buyers are encouraged to remain proactive in their sourcing strategies, embracing innovation and prioritizing quality. By doing so, they will not only enhance their competitive edge but also contribute to improved patient outcomes across diverse markets in Africa, South America, the Middle East, and Europe.