Introduction: Navigating the Global Market for simple dental implants

In the competitive landscape of dental care, simple dental implants stand out as a critical solution for restoring oral function and aesthetics. These implants not only enhance patient satisfaction but also represent a significant opportunity for international B2B buyers seeking to source reliable and effective dental solutions. As the demand for dental implants continues to rise, understanding the intricacies of the market becomes essential for informed purchasing decisions.

This comprehensive guide serves as a valuable resource for B2B buyers from regions including Africa, South America, the Middle East, and Europe, such as Nigeria and Italy. We delve into various aspects of simple dental implants, covering types and materials used, insights into manufacturing and quality control processes, and key suppliers in the industry. Additionally, we provide an overview of cost factors and the current market trends shaping the dental implant sector.

By equipping international buyers with actionable insights and critical information, this guide empowers them to navigate the complexities of sourcing simple dental implants. Whether you are looking to enhance your product offerings or establish new partnerships, understanding these elements will aid in making strategic decisions that drive success in the dental market.

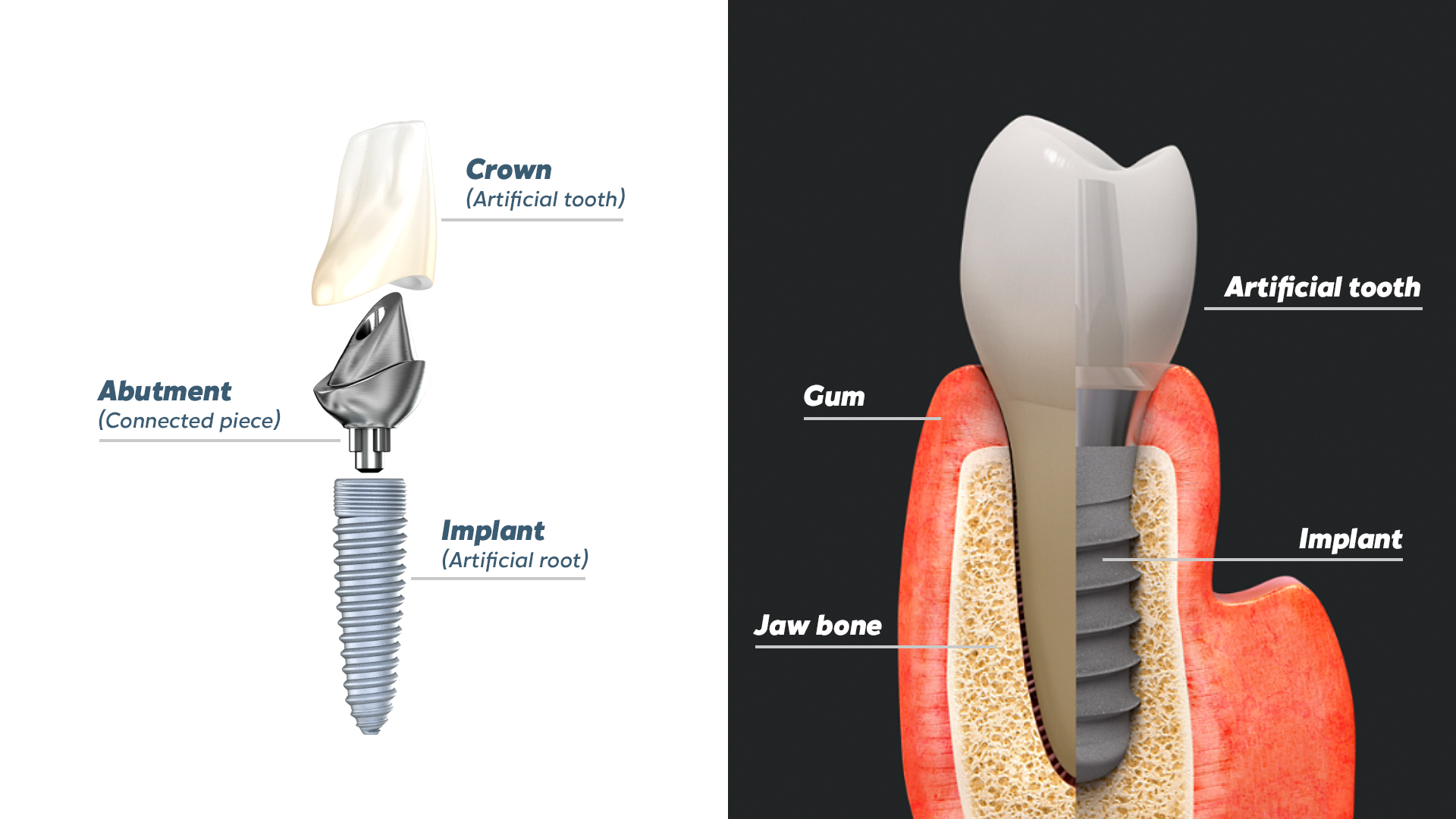

Understanding simple dental implants Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Endosteal Implants | Placed within the jawbone, cylindrical or tapered shape | General dentistry, oral surgery | Pros: High success rate, durable. Cons: Requires sufficient bone density. |

| Subperiosteal Implants | Positioned under the gum but above the jawbone | Patients with minimal bone structure | Pros: Less invasive, suitable for those lacking bone. Cons: Higher cost, less common. |

| Mini Dental Implants | Smaller diameter, often used for denture stabilization | Prosthodontics, orthodontics | Pros: Minimally invasive, quicker recovery. Cons: Limited applications, lower load-bearing capacity. |

| Zygomatic Implants | Anchored in the zygomatic bone (cheekbone) | Complex cases with severe bone loss | Pros: Ideal for patients with significant jawbone loss. Cons: Technical complexity, higher costs. |

| Immediate Load Implants | Allows for same-day placement of crowns or dentures | Fast-track dental solutions | Pros: Immediate aesthetic results, patient satisfaction. Cons: Requires careful case selection, higher risk of failure. |

Endosteal Implants

Endosteal implants are the most common type of dental implant, featuring a cylindrical or tapered design that is surgically placed directly into the jawbone. This type is typically used in general dentistry and oral surgery applications. For B2B buyers, key considerations include the need for adequate bone density in patients, which may necessitate additional procedures such as bone grafting. The high success rate and durability of endosteal implants make them a preferred choice in many clinical settings.

Subperiosteal Implants

Subperiosteal implants are designed for patients who may not have sufficient bone height for traditional endosteal implants. They are placed under the gum tissue but above the jawbone, making them less invasive. This type is particularly beneficial for patients with significant bone loss. B2B buyers should consider the higher costs associated with subperiosteal implants and the need for specialized training for placement. Their use is less common, but they serve a critical role in specific patient populations.

Mini Dental Implants

Mini dental implants are smaller in diameter and are often used to stabilize dentures, making them an attractive option in prosthodontics and orthodontics. Their minimally invasive nature allows for quicker recovery times, appealing to both patients and dental practitioners. However, B2B buyers should be aware that mini implants have limited applications and a lower load-bearing capacity compared to traditional implants. This makes them suitable primarily for specific cases where conventional implants are not feasible.

Zygomatic Implants

Zygomatic implants are a specialized type of implant anchored in the zygomatic bone, making them ideal for patients with severe jawbone loss. This type is particularly useful in complex cases where traditional implants cannot be placed due to insufficient bone structure. B2B buyers should note the technical complexity and higher costs associated with zygomatic implants, which require skilled professionals for placement. Their unique application can significantly improve patient outcomes in challenging scenarios.

Immediate Load Implants

Immediate load implants allow for the placement of crowns or dentures on the same day as the implant surgery, providing rapid aesthetic results. This approach is particularly appealing in fast-track dental solutions and can enhance patient satisfaction. However, B2B buyers must consider the careful selection of cases for immediate loading, as there is a higher risk of failure if not executed properly. This type of implant necessitates a thorough understanding of patient conditions and implant stability.

Related Video: DENTAL IMPLANTS : TYPES, SURFACE TREATMENTS, why TITANIUM is used for making implants?

Key Industrial Applications of simple dental implants

| Industry/Sector | Specific Application of Simple Dental Implants | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Replacement of missing teeth | Enhances patient satisfaction and retention | Quality certifications (ISO 13485), reliable supply chains |

| Dental Laboratories | Custom abutment manufacturing | Streamlines production processes and reduces turnaround time | Precision manufacturing capabilities, material sourcing |

| Orthodontics | Support for orthodontic devices | Provides stability in orthodontic treatments | Compatibility with existing orthodontic systems, regulatory approvals |

| Maxillofacial Surgery | Reconstruction after trauma or disease | Restores functionality and aesthetics for patients | Comprehensive training for surgical teams, integration with implants |

| Prosthodontics | Fixed prosthetics and dentures | Increases patient comfort and improves quality of life | Durability and biocompatibility of materials, post-operative care |

Detailed Applications

Dental Clinics

Simple dental implants are primarily used in dental clinics for the replacement of missing teeth. This application not only restores functionality but also significantly enhances the aesthetic appearance of patients. For international B2B buyers, especially in regions like Africa and South America, sourcing high-quality implants that comply with local regulations is crucial. Clinics benefit from ensuring that the implants are backed by strong warranties and have a proven track record in patient outcomes.

Dental Laboratories

In dental laboratories, simple dental implants are employed for the custom manufacturing of abutments. This application allows for the precise fit and alignment needed for effective dental restoration. Buyers in this sector should consider suppliers with advanced precision manufacturing capabilities and a robust quality management system to ensure that the products meet the required standards. Fast turnaround times and reliable delivery schedules are also critical for maintaining workflow efficiency.

Orthodontics

Orthodontic practices utilize simple dental implants to provide support for various orthodontic devices. These implants offer a stable foundation, facilitating the effective application of braces and aligners. For B2B buyers in Europe or the Middle East, it is essential to ensure that the implants are compatible with existing orthodontic systems and come with necessary regulatory approvals. This compatibility minimizes the risk of complications during treatment and enhances patient satisfaction.

Maxillofacial Surgery

In the field of maxillofacial surgery, simple dental implants are used for reconstructive purposes following trauma or disease. These implants restore not only the functionality of the jaw but also the aesthetic integrity of the face. International buyers must prioritize suppliers who provide comprehensive training for surgical teams and have a strong support system for post-operative care. The ability to integrate these implants seamlessly with other surgical interventions is also vital.

Prosthodontics

Prosthodontists utilize simple dental implants for fixed prosthetics and dentures, significantly improving patient comfort and quality of life. By anchoring dentures securely, these implants prevent slippage and enhance chewing efficiency. For B2B buyers, particularly in Italy and other European countries, it is important to source implants that demonstrate durability and biocompatibility. Ensuring that the implants come with adequate post-operative support can also enhance patient outcomes and satisfaction.

Related Video: Step by Step Dental Implant Procedure – Back Molar

Strategic Material Selection Guide for simple dental implants

When selecting materials for simple dental implants, international B2B buyers must consider various factors, including mechanical properties, manufacturing complexity, cost, and regulatory compliance. Here, we analyze four common materials used in dental implants: Titanium, Zirconia, Stainless Steel, and Polyether Ether Ketone (PEEK). Each material has distinct characteristics that influence its suitability for different applications.

Titanium

Key Properties: Titanium is known for its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. It can withstand significant mechanical loads and is resistant to bodily fluids, making it ideal for long-term use in dental applications.

Pros & Cons: The primary advantage of titanium is its durability and ability to integrate with bone (osseointegration). However, it is relatively expensive compared to other materials, and its machining can be complex due to its toughness.

Impact on Application: Titanium is compatible with various dental environments, including those exposed to saline solutions. Its corrosion resistance ensures longevity, making it a preferred choice for permanent implants.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with standards such as ISO 13485 and ASTM F136. Additionally, understanding local regulations regarding titanium sourcing and processing is crucial.

Zirconia

Key Properties: Zirconia is a ceramic material noted for its high strength, toughness, and aesthetic appeal. It is also highly resistant to wear and corrosion, making it suitable for dental applications.

Pros & Cons: Zirconia’s primary advantage is its excellent aesthetic quality, closely mimicking natural tooth color. However, it can be more brittle than metals, leading to potential fracture under extreme stress.

Impact on Application: Ideal for patients seeking cosmetic solutions, zirconia implants are particularly effective in anterior (front) dental applications where appearance is paramount.

Considerations for International Buyers: Buyers should be aware of the need for precise manufacturing processes to avoid defects. Compliance with ISO standards and local regulations is essential, especially in Europe, where stringent guidelines apply.

Stainless Steel

Key Properties: Stainless steel is known for its good mechanical properties, corrosion resistance, and affordability. It is commonly used in temporary dental implants and tools.

Pros & Cons: The main advantage of stainless steel is its cost-effectiveness and ease of fabrication. However, it may not provide the same level of osseointegration as titanium, making it less suitable for long-term implants.

Impact on Application: Stainless steel is often used for temporary solutions or in situations where cost is a significant factor. It is compatible with various dental environments but may corrode over time if not properly treated.

Considerations for International Buyers: Buyers must ensure that the stainless steel used meets relevant standards such as ASTM A276. Understanding local corrosion resistance requirements is also critical, especially in humid regions.

Polyether Ether Ketone (PEEK)

Key Properties: PEEK is a high-performance polymer that offers excellent mechanical properties, thermal stability, and chemical resistance. It is lightweight and biocompatible.

Pros & Cons: The main advantage of PEEK is its flexibility and ability to mimic the mechanical properties of bone. However, it is less commonly used for permanent implants due to its lower strength compared to metals.

Impact on Application: PEEK is suitable for specific applications where flexibility and weight are critical, such as in certain implant designs or for temporary solutions.

Considerations for International Buyers: Buyers should verify that PEEK materials comply with ISO 10993 for biocompatibility. Understanding the regulatory landscape in regions like the Middle East and Europe is essential for successful market entry.

Summary Table

| Material | Typical Use Case for simple dental implants | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Permanent dental implants | Excellent osseointegration | High cost and complex machining | High |

| Zirconia | Anterior dental implants | Aesthetic appeal | Brittle under stress | Medium |

| Stainless Steel | Temporary dental implants | Cost-effective | Less osseointegration | Low |

| Polyether Ether Ketone (PEEK) | Flexible implant designs | Lightweight and biocompatible | Lower strength compared to metals | Medium |

This strategic material selection guide aims to provide B2B buyers with actionable insights to make informed decisions when sourcing materials for simple dental implants, ensuring compliance with international standards and suitability for their specific markets.

In-depth Look: Manufacturing Processes and Quality Assurance for simple dental implants

The manufacturing of simple dental implants involves a series of well-defined processes that ensure both functionality and compliance with international quality standards. For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes and the associated quality assurance measures is crucial for making informed purchasing decisions.

Manufacturing Processes

1. Material Preparation

The first stage in manufacturing dental implants involves selecting and preparing suitable materials, primarily titanium or zirconia. These materials are chosen for their biocompatibility, strength, and resistance to corrosion.

- Material Sourcing: B2B buyers should ensure that materials are sourced from reputable suppliers who can provide certification of material properties and compliance with international standards.

- Material Testing: Before processing, materials undergo rigorous testing for purity and mechanical properties to ensure they meet the required specifications.

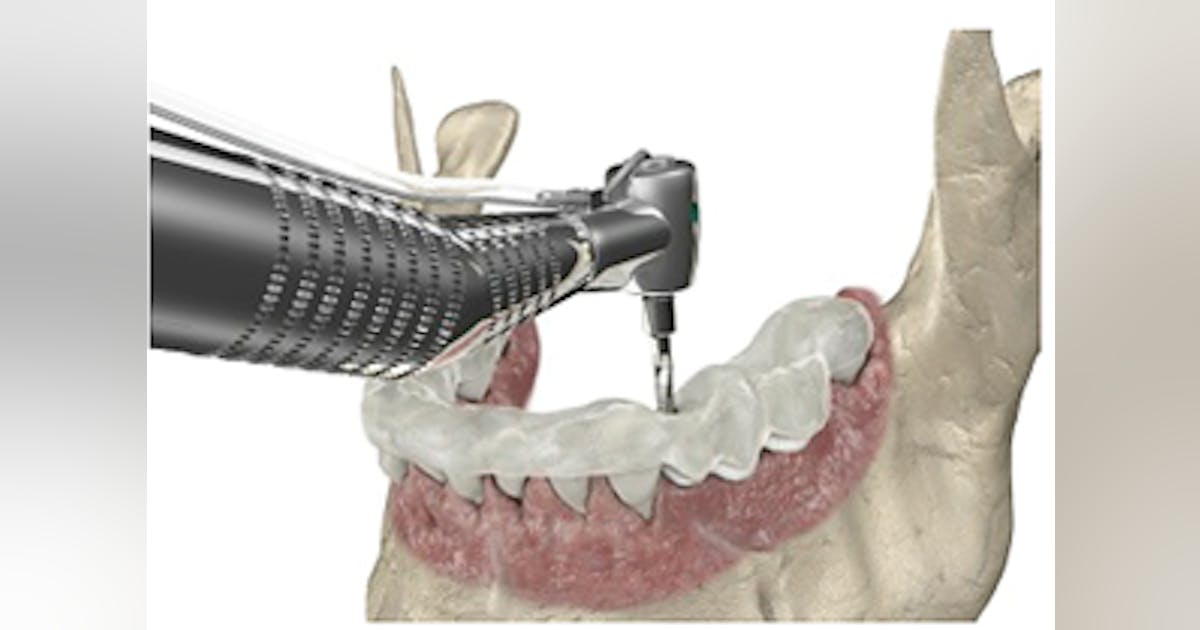

2. Forming

Forming is the next critical phase where the raw materials are shaped into the desired form of the dental implant. Common techniques include:

- CNC Machining: Computer Numerical Control (CNC) machining is widely used for creating precise components. This method allows for high accuracy and repeatability, essential for dental implants.

- Additive Manufacturing: This technique, also known as 3D printing, is increasingly utilized for creating complex geometries that traditional methods cannot achieve. It is particularly beneficial for producing customized implants.

3. Assembly

In the assembly stage, components such as the implant body and abutments are brought together. This process often includes:

- Micro-assembly Techniques: Specialized tools and techniques are employed to ensure precision during assembly, which is critical for the functionality of the implant.

- Integration of Additional Components: Depending on the implant design, other components such as screws and healing caps are integrated.

4. Finishing

Finishing processes enhance the surface quality and functionality of the implants. This stage typically includes:

- Surface Treatment: Techniques such as sandblasting, acid etching, or anodization are used to improve the surface roughness, which is crucial for osseointegration.

- Polishing: Final polishing ensures that the implants have a smooth surface finish, reducing the risk of infection and improving aesthetic outcomes.

Quality Assurance

Quality assurance (QA) is paramount in the dental implant manufacturing process. B2B buyers must be aware of the relevant standards and checkpoints throughout the production process.

International Standards

Several international standards govern the manufacturing and quality assurance of dental implants:

- ISO 13485: This quality management standard is specific to medical devices and outlines the requirements for a comprehensive quality management system.

- CE Marking: For European markets, obtaining CE marking demonstrates that the product meets health, safety, and environmental protection standards.

- FDA Regulations: In the United States, compliance with FDA regulations, including 21 CFR Part 820, is essential for manufacturers.

Key Quality Control Checkpoints

Quality control (QC) checkpoints are integrated throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial phase involves inspecting raw materials and components to ensure they meet predefined specifications before they enter production.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring and testing are performed to identify any deviations from quality standards. This might include dimensional checks and surface quality inspections.

- Final Quality Control (FQC): Once manufacturing is complete, the finished implants undergo final inspections and testing to verify that they meet all specifications and regulatory requirements.

Common Testing Methods

Testing methods employed in the quality assurance process include:

- Mechanical Testing: Tensile strength, fatigue, and impact resistance tests are performed to ensure the implants can withstand physiological loads.

- Biocompatibility Testing: This testing assesses the materials’ compatibility with biological systems, ensuring they do not elicit adverse reactions.

- Sterility Testing: For implants that will be used in surgical applications, sterility is critical. Manufacturers must ensure that their products are free from viable microorganisms.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality control measures of potential suppliers. Key strategies include:

- Conducting Audits: Regular audits of suppliers can provide insights into their quality management practices and compliance with international standards.

- Requesting Quality Reports: Buyers should ask for quality reports that detail inspection results, testing methods, and compliance with relevant standards.

- Third-Party Inspections: Engaging third-party organizations to conduct independent inspections can help validate the quality claims made by suppliers.

Quality Control and Certification Nuances for International Buyers

For international buyers, understanding the nuances of quality control and certification processes is essential.

- Regional Compliance: Different regions may have specific regulatory requirements. For instance, while CE marking is crucial for European markets, buyers in Africa or South America may need to consider local certifications and standards.

- Documentation Requirements: Buyers should ensure that all necessary documentation, including certificates of compliance and test reports, is provided by suppliers to facilitate smoother import processes.

By understanding the manufacturing processes and quality assurance measures for simple dental implants, B2B buyers can make informed decisions, ensuring they procure high-quality products that meet both clinical and regulatory requirements.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for simple dental implants Sourcing

Understanding the cost and pricing structure of simple dental implants is crucial for international B2B buyers aiming to optimize their sourcing strategies. This analysis delves into the various cost components, price influencers, and actionable tips for buyers, particularly from regions such as Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The choice of materials significantly impacts the overall cost. Titanium and zirconia are the most common materials used in dental implants due to their biocompatibility and strength. Prices can vary based on the quality and source of these materials.

-

Labor: Labor costs are influenced by the region of manufacturing. In countries with higher labor costs, such as those in Western Europe, the price of implants may be elevated compared to regions with lower labor costs, such as parts of Asia or South America.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead, leading to lower overall prices.

-

Tooling: The cost of specialized tools and machinery required for implant production can be substantial. Investing in high-precision manufacturing equipment can improve production quality but may also increase initial costs.

-

Quality Control (QC): Compliance with international standards (e.g., ISO 13485, FDA regulations) necessitates a robust QC system, which adds to the overall manufacturing cost. Buyers should consider the value of certifications when evaluating suppliers.

-

Logistics: Transportation and shipping costs can vary widely depending on the distance, mode of transport, and Incoterms used. Efficient logistics can minimize costs, but this requires careful planning and negotiation.

-

Margin: Suppliers typically add a profit margin to cover risks and ensure business sustainability. Margins can vary based on market demand and competition.

Price Influencers

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their needs to maximize cost efficiency.

-

Specifications/Customization: Customized implants may incur additional costs due to the need for tailored tooling and manufacturing processes. Buyers should weigh the benefits of customization against these potential price increases.

-

Materials and Quality: The choice of material and the quality of the implants directly influence the price. High-quality implants may come at a premium but can lead to better patient outcomes and lower long-term costs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a track record of quality may charge more, but they often provide better service and support.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) is essential for managing logistics costs. Buyers should clarify responsibilities for shipping costs and risks to avoid unexpected expenses.

Buyer Tips

-

Negotiation: Engage in discussions with multiple suppliers to explore competitive pricing. Leverage volume discounts and long-term contracts to secure favorable terms.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the purchase price. Consider factors such as durability, warranty, and potential complications that could arise from lower-quality products.

-

Pricing Nuances: Be aware of regional pricing differences due to market dynamics. For instance, buyers in Africa may face different cost structures compared to those in Europe, influenced by local regulations and supply chain conditions.

-

Research and Due Diligence: Conduct thorough research on potential suppliers, including their certifications, manufacturing capabilities, and customer reviews. This will help ensure that you are sourcing high-quality implants at a reasonable price.

Disclaimer

The prices for dental implants can vary significantly based on the factors outlined above. It is essential for buyers to conduct their own market research and consult with suppliers for the most accurate and up-to-date pricing information.

Essential Technical Properties and Trade Terminology for simple dental implants

When considering simple dental implants, international B2B buyers must understand several critical technical properties and industry-specific terminology. This knowledge ensures informed purchasing decisions, compliance with regulations, and alignment with market standards.

Key Technical Properties of Simple Dental Implants

-

Material Grade

– Dental implants are typically made from titanium or zirconia. Titanium, known for its biocompatibility and strength, is the most common choice. Understanding the material grade helps buyers assess the implant’s durability and suitability for specific clinical applications, particularly in diverse markets like Africa and South America, where conditions may vary. -

Tolerance

– Tolerance refers to the permissible limits of variation in the implant’s dimensions. For dental implants, a tighter tolerance is crucial for ensuring proper fit and function. High-precision manufacturing minimizes the risk of complications during surgical procedures, which is particularly important in regions with limited access to follow-up care.

-

Surface Treatment

– The surface of dental implants often undergoes treatment to enhance osseointegration (the process by which the implant anchors to the bone). Treatments like sandblasting or acid etching increase surface roughness, promoting better bone contact. Buyers should evaluate the effectiveness of these treatments, as they directly influence the implant’s long-term success rates. -

Load-Bearing Capacity

– This property defines how much force an implant can withstand during chewing and other activities. Understanding load-bearing capacity is essential for ensuring that the selected implants can support the intended dental applications, especially for patients in regions where dietary habits may impose additional stress on dental restorations. -

Corrosion Resistance

– Dental implants must resist corrosion to maintain their integrity over time. Titanium alloys are often used due to their excellent corrosion resistance in the oral environment. Buyers should inquire about corrosion testing results to ensure the longevity and reliability of the implants.

Common Trade Terminology in Dental Implants

- OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and the origin of their products, which is particularly important when sourcing implants from different regions.

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

– This term refers to the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management. Buyers should negotiate MOQs that align with their market demand, especially in emerging markets where demand may be unpredictable. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It is an essential step in the procurement process, allowing buyers to compare costs and features. Buyers should provide detailed specifications in their RFQ to receive accurate and competitive quotes. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers to avoid misunderstandings and ensure compliance with international trade regulations. -

CE Marking

– The CE marking indicates that a product meets European health, safety, and environmental protection standards. For buyers in Europe, understanding the importance of CE marking is essential for regulatory compliance and market access. -

FDA Approval

– In the United States, dental implants must receive FDA approval to ensure they meet safety and efficacy standards. Buyers should verify FDA status for implants, especially when sourcing from manufacturers outside the U.S., to ensure compliance with local regulations.

By grasping these essential properties and terminology, international B2B buyers can enhance their procurement strategies, ensuring they select the most suitable products for their markets while adhering to industry standards.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the simple dental implants Sector

Market Overview & Key Trends

The dental implant market is experiencing robust growth, driven by an increasing demand for dental restoration and cosmetic procedures globally. Factors such as rising disposable incomes, an aging population, and heightened awareness regarding oral health are propelling this trend. For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging technologies are reshaping the landscape of dental implants. Innovations such as digital dentistry, including CAD/CAM systems and 3D printing, are enhancing precision and efficiency in the manufacturing process. Furthermore, minimally invasive techniques are becoming increasingly popular, reducing recovery times and improving patient satisfaction. B2B buyers should consider partnerships with manufacturers that utilize these advanced technologies to stay competitive.

Moreover, the demand for customized solutions is on the rise. Buyers are encouraged to engage with suppliers who offer tailored dental implants that meet specific patient needs, as personalization is becoming a key differentiator in the market. As international trade barriers diminish, buyers from diverse regions can access a broader range of products, making it essential to evaluate suppliers based on their technological capabilities and product offerings.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal consideration in the sourcing of dental implants. The environmental impact of manufacturing processes, including waste generation and resource depletion, is under scrutiny. B2B buyers are increasingly seeking suppliers that adhere to sustainable practices to mitigate these impacts.

Ethical sourcing is equally important. Buyers should prioritize suppliers who maintain transparent supply chains and adhere to ethical labor practices. This includes ensuring that materials used in dental implants are sourced responsibly, minimizing harm to ecosystems and communities. Certifications such as ISO 14001 for environmental management and ISO 13485 for quality management in medical devices can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, the use of biodegradable materials and recyclable packaging is gaining traction. Buyers should engage with manufacturers that invest in research and development to create eco-friendly alternatives, as these innovations not only enhance brand reputation but also align with growing consumer preferences for sustainability.

Brief Evolution/History

The simple dental implant sector has evolved significantly since its inception in the mid-20th century. Initially, dental implants were rudimentary and often failed due to inadequate integration with bone structures. The introduction of titanium implants in the 1960s marked a turning point, as titanium’s biocompatibility improved success rates dramatically.

Over the years, advancements in materials science and manufacturing technologies have led to the development of more sophisticated implants, including zirconia implants and customized solutions using 3D printing. This evolution has not only enhanced the durability and aesthetics of implants but has also increased their accessibility, making them a viable option for a broader range of patients. For B2B buyers, understanding this historical context is vital for recognizing the quality and innovation behind contemporary dental implant offerings.

Related Video: Global Trends Tutorial: Chapter 3: IPE

Frequently Asked Questions (FAQs) for B2B Buyers of simple dental implants

-

What should I look for when vetting suppliers of simple dental implants?

When vetting suppliers, prioritize certifications such as ISO 13485 and compliance with local regulations (e.g., CE marking in Europe, FDA in the U.S.). Investigate their manufacturing capabilities, quality control processes, and production history. Request references from other clients and check for any past compliance issues. Additionally, assess their ability to customize products to meet your specific market needs, particularly considering the varying regulatory environments in regions like Africa, South America, and the Middle East. -

Can I customize simple dental implants to suit my market needs?

Yes, many manufacturers offer customization options for dental implants. You can request modifications in design, materials, and packaging to align with local preferences and regulatory requirements. It’s essential to communicate your specifications clearly and ensure that the supplier has the technical capability to deliver on your requirements. Always confirm that any customization complies with local regulations and safety standards to avoid future complications. -

What are the typical minimum order quantities (MOQs) and lead times for dental implants?

MOQs can vary significantly based on the supplier and product type. Generally, for dental implants, MOQs range from 50 to 500 units, depending on the complexity of the customization and production capabilities. Lead times typically range from 4 to 12 weeks, influenced by factors such as production schedules, material availability, and shipping logistics. Discussing these details upfront with your supplier can help you plan your inventory and meet market demand effectively. -

What payment terms are common when sourcing dental implants internationally?

Payment terms can vary widely among suppliers. Common practices include 30% upfront payment with the balance due upon delivery or after inspection. Some suppliers may also accept letters of credit or escrow services to safeguard both parties. It’s crucial to negotiate terms that protect your interests while ensuring the supplier feels secure in their transaction. Always ensure that payment methods comply with international trade regulations and are suitable for your region. -

How can I ensure quality assurance for the dental implants I purchase?

To ensure quality, request detailed documentation of the supplier’s quality management systems and certifications. Ask for test reports and compliance certificates for the implants you are purchasing. Conducting regular audits and inspections, either in-person or through third-party services, can also help maintain standards. Establishing a clear return policy and warranty terms will further safeguard your investment in case of defective products. -

What logistics considerations should I be aware of when importing dental implants?

Logistics play a crucial role in the timely delivery of dental implants. Be aware of shipping regulations, customs duties, and import tariffs specific to your country. Collaborate with experienced logistics providers familiar with medical devices to navigate the complexities of international shipping. Additionally, consider factors like temperature control and packaging requirements to ensure product integrity during transit, especially for regions with varying climates. -

How can I handle disputes with suppliers effectively?

Establishing a clear contract that outlines all terms of the agreement, including quality standards, delivery timelines, and dispute resolution processes, is essential. In case of a dispute, start by communicating directly with the supplier to find an amicable solution. If necessary, consider mediation or arbitration as alternative dispute resolution methods, which can be more efficient than legal action. Always document all communications and agreements to support your position during disputes. -

What certifications should I expect from a reliable supplier of dental implants?

A reliable supplier should hold certifications such as ISO 13485 for quality management in medical devices, as well as relevant local certifications (e.g., CE marking in Europe, FDA approval in the U.S.). Additionally, check for compliance with regional health and safety regulations. Suppliers should be willing to provide copies of their certificates and any inspection reports to ensure transparency and build trust in their products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for simple dental implants

In conclusion, effective strategic sourcing of simple dental implants is essential for international B2B buyers seeking competitive advantages in their markets. By prioritizing partnerships with manufacturers that uphold rigorous quality standards, such as ISO 13485 and FDA regulations, buyers can ensure they are sourcing reliable products that meet global compliance needs. Additionally, leveraging precision manufacturing capabilities enhances product reliability and performance, which is crucial in the dental sector.

For buyers in regions like Africa, South America, the Middle East, and Europe, understanding local regulatory landscapes and engaging with suppliers familiar with these requirements can facilitate smoother procurement processes. Establishing long-term relationships with trusted suppliers not only reduces costs but also fosters innovation and responsiveness to market demands.

As the dental implant market continues to evolve, embracing new technologies and manufacturing processes will be key. We encourage B2B buyers to explore emerging trends in implant design and materials, as well as to stay informed about regulatory updates that could impact sourcing decisions. By taking proactive steps now, businesses can position themselves for success in a competitive landscape and better serve their customers’ needs in the future.

Illustrative Image (Source: Google Search)