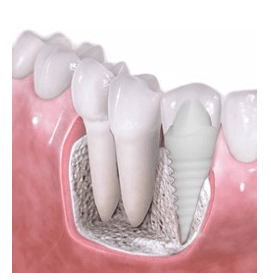

Introduction: Navigating the Global Market for zircon dental implants

In the rapidly evolving landscape of dental technology, zircon dental implants stand out as a beacon of innovation and reliability. For B2B buyers across Africa, South America, the Middle East, and Europe, understanding the intricacies of zircon implants is crucial for enhancing patient outcomes and staying competitive in the marketplace. These implants are not only biocompatible and aesthetically pleasing but also offer superior strength and durability, making them an ideal choice for dental professionals aiming to provide the best care.

This comprehensive guide aims to equip international buyers with the insights necessary to navigate the global zircon dental implant market. We will explore various types of zircon implants, delve into the materials and manufacturing processes that ensure quality, and highlight key suppliers that can meet diverse needs. Additionally, we will discuss cost considerations, market trends, and frequently asked questions to demystify the procurement process.

By leveraging this guide, B2B buyers can make informed sourcing decisions that enhance their product offerings and improve customer satisfaction. Whether you are in Nigeria, South Africa, or any other region, understanding the nuances of zircon dental implants will empower you to make strategic choices that align with your business objectives. Embrace the opportunity to enhance your competitive edge in the dental industry by mastering the essentials of zircon implants today.

Understanding zircon dental implants Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solid Zirconia Implants | Monolithic structure, high strength | General dentistry, single-tooth replacements | Pros: Biocompatible, aesthetic; Cons: Limited flexibility in design. |

| Zirconia Framework Implants | Hybrid design with zirconia and metal | Complex restorations, multi-unit bridges | Pros: Enhanced strength, versatility; Cons: Higher cost, potential for metal sensitivity. |

| Anatomic Zirconia Implants | Tailored to anatomical structures | Personalized treatments, implant-supported prosthetics | Pros: Improved fit and function; Cons: Requires specialized manufacturing. |

| Zirconia Coated Implants | Titanium core with zirconia coating | Cases requiring both strength and aesthetics | Pros: Combines durability with aesthetic appeal; Cons: Coating may wear over time. |

| Translucent Zirconia Implants | High translucency for natural appearance | Aesthetic-driven cases, anterior teeth | Pros: Excellent aesthetics, mimics natural teeth; Cons: May be less durable than opaque options. |

Solid Zirconia Implants

Solid zirconia implants are characterized by their monolithic design, which provides exceptional strength and durability. These implants are suitable for straightforward restorative cases, particularly in single-tooth replacements. When considering procurement, buyers should evaluate the supplier’s quality assurance processes, as the integrity of solid zirconia is crucial for long-term success. Additionally, while these implants offer excellent biocompatibility and aesthetic results, their design limits flexibility in complex restorations.

Zirconia Framework Implants

Zirconia framework implants integrate zirconia with metal components, offering enhanced strength and durability for more complex dental restorations. These implants are primarily used in multi-unit bridges where structural integrity is paramount. B2B buyers should assess the compatibility of these implants with existing dental systems and consider the potential for increased costs due to their hybrid nature. While they provide versatility in design, the presence of metal may be a concern for patients with sensitivities.

Anatomic Zirconia Implants

Anatomic zirconia implants are specifically designed to match the unique anatomical features of a patient’s jaw. This customization allows for better integration and functionality, making them ideal for personalized treatments, including implant-supported prosthetics. For B2B buyers, understanding the manufacturing capabilities of suppliers is essential, as these implants require precise fabrication techniques. While they offer significant advantages in terms of fit and performance, the specialized nature can lead to longer lead times and higher costs.

Zirconia Coated Implants

Zirconia coated implants consist of a titanium core that is coated with zirconia, combining the strength of titanium with the aesthetic benefits of zirconia. These implants are particularly beneficial in cases where both durability and aesthetics are required. Buyers should consider the longevity of the zirconia coating, as wear over time could affect performance. While they present a balanced solution, the dual material aspect can complicate the manufacturing process, potentially impacting availability.

Translucent Zirconia Implants

Translucent zirconia implants are designed to mimic the natural translucency of teeth, making them an excellent choice for aesthetic-driven cases, particularly in the anterior region. These implants are favored for their ability to blend seamlessly with natural dentition. B2B buyers should focus on the supplier’s ability to produce high-quality translucent materials, as the aesthetic outcome is heavily reliant on this factor. However, it is important to note that these implants may not be as durable as their opaque counterparts, necessitating careful consideration of their application.

Related Video: Types of Zirconia Crowns & Which one is the Best for Dentistry Abroad?

Key Industrial Applications of zircon dental implants

| Industry/Sector | Specific Application of zircon dental implants | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Replacement of missing teeth | High patient satisfaction due to aesthetic and functional benefits | Ensure compatibility with existing dental equipment and procedures |

| Dental Laboratories | Custom implant fabrication | Ability to offer tailored solutions, enhancing service diversity | Source high-quality zirconia for durability and biocompatibility |

| Orthodontics | Support for orthodontic appliances | Improved patient outcomes with less visible implants | Consider the weight and strength of materials for optimal performance |

| Medical Device Manufacturing | Production of surgical tools and implants | Streamlined production processes with advanced materials | Evaluate suppliers for compliance with international quality standards |

| Aesthetic Dentistry | Cosmetic enhancements for implants | Increased demand for aesthetic solutions among patients | Look for innovative designs and finishes that enhance aesthetics |

Detailed Applications of Zircon Dental Implants

Dental Clinics

Zircon dental implants are increasingly used in dental clinics as a reliable solution for replacing missing teeth. Their biocompatibility and aesthetic properties make them a preferred choice among practitioners, leading to high patient satisfaction. For international buyers, particularly in regions like Africa and South America, it’s essential to ensure that the implants integrate seamlessly with existing dental practices. This includes verifying the compatibility of zircon implants with the clinic’s tools and techniques, ensuring optimal patient outcomes.

Dental Laboratories

In dental laboratories, zircon dental implants are utilized for custom fabrication, allowing technicians to create tailored solutions for diverse patient needs. This flexibility enhances the laboratory’s service offerings and can lead to increased customer loyalty. Buyers in the Middle East and Europe should prioritize sourcing high-quality zirconia materials that promise durability and biocompatibility. Establishing relationships with reputable suppliers can also ensure consistent quality and timely delivery, crucial for maintaining laboratory operations.

Orthodontics

Zircon dental implants also play a significant role in orthodontics, where they serve as anchors for various orthodontic appliances. Their strength and reduced visibility can lead to improved patient outcomes, particularly in aesthetic treatments. B2B buyers in Africa should consider the weight and strength of zircon materials to ensure they meet the specific requirements of orthodontic applications. Collaborating with manufacturers who specialize in orthodontic solutions can provide insights into the latest advancements in implant technology.

Medical Device Manufacturing

Zircon dental implants are integral to the production of surgical tools and implants within the medical device manufacturing sector. The use of advanced zircon materials can streamline manufacturing processes, reduce costs, and enhance product performance. International buyers, particularly from Europe, should evaluate suppliers based on their compliance with international quality standards, ensuring that the implants meet regulatory requirements for safety and effectiveness.

Aesthetic Dentistry

In aesthetic dentistry, zircon dental implants are favored for cosmetic enhancements, providing patients with natural-looking results. The growing demand for aesthetic solutions presents a lucrative opportunity for businesses in this sector. Buyers in South America and the Middle East should focus on sourcing innovative designs and finishes that not only enhance the aesthetic appeal but also maintain the structural integrity of the implants. Engaging with suppliers who understand the latest trends in aesthetic dentistry can provide a competitive edge.

Related Video: Titanium vs Ceramic (Zirconia): Choosing The Right Dental Implants For You

Strategic Material Selection Guide for zircon dental implants

When selecting materials for zircon dental implants, it is essential to consider various properties that directly affect performance, longevity, and compatibility with biological environments. Below is an analysis of four common materials used in zircon dental implants, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Zirconia (ZrO2)

Key Properties:

Zirconia is known for its excellent mechanical strength, high fracture toughness, and superior biocompatibility. It can withstand high temperatures and pressures, making it suitable for various dental applications. Additionally, zirconia exhibits low thermal conductivity, which is beneficial for patient comfort.

Pros & Cons:

The primary advantage of zirconia is its aesthetic appeal, closely resembling natural tooth color. It is also highly resistant to wear and corrosion, ensuring durability. However, the manufacturing process can be complex and costly, which may affect the overall price point for buyers.

Impact on Application:

Zirconia is compatible with a range of dental media, including saliva and oral bacteria, making it ideal for long-term implants. Its resistance to staining and discoloration enhances its suitability for aesthetic restorations.

Considerations for International Buyers:

Buyers must ensure compliance with international standards such as ISO 6872 and ASTM F1562. Understanding regional preferences for aesthetics and biocompatibility is crucial, especially in markets like South Africa and Nigeria, where consumer expectations may vary.

2. Alumina (Al2O3)

Key Properties:

Alumina is characterized by its high hardness and excellent wear resistance. It can withstand significant mechanical stress and has good thermal stability, making it a reliable choice for dental applications.

Pros & Cons:

Alumina offers a lower cost compared to zirconia, making it an attractive option for budget-conscious buyers. However, it is less aesthetically pleasing and can be more brittle, leading to a higher risk of fracture under certain conditions.

Impact on Application:

Alumina is suitable for applications requiring high wear resistance, such as abutments. However, its lower aesthetic quality may limit its use in visible areas.

Considerations for International Buyers:

Buyers should be aware of the varying regulatory standards across regions. For instance, South American countries may have different compliance requirements compared to those in Europe. Understanding local market preferences for aesthetics versus functionality is vital.

3. Composite Resins

Key Properties:

Composite resins are made from a mixture of organic polymers and inorganic fillers, providing a balance of strength and flexibility. They are lightweight and can be molded into various shapes, which is advantageous for custom applications.

Pros & Cons:

The primary benefit of composite resins is their versatility and lower cost compared to ceramics. However, they may not offer the same level of durability or wear resistance, leading to potential issues in high-stress applications.

Impact on Application:

Composite resins are often used in temporary restorations or as a base material for other dental procedures. Their compatibility with various bonding agents makes them suitable for diverse applications.

Considerations for International Buyers:

Buyers should consider the lifespan and performance of composite resins in their specific market conditions. Compliance with standards like ASTM D685 and ISO 4049 is essential, especially in regions with stringent regulations.

4. Titanium (Ti)

Key Properties:

Titanium is well-known for its high strength-to-weight ratio and excellent corrosion resistance. It has a proven track record in dental implants due to its biocompatibility and ability to integrate with bone.

Pros & Cons:

The key advantage of titanium is its durability and long-term success in various clinical applications. However, it is heavier than zirconia and may not offer the same aesthetic appeal, which can be a drawback for some patients.

Impact on Application:

Titanium is particularly suitable for load-bearing implants and is often used in conjunction with zirconia for hybrid solutions. Its compatibility with biological tissues ensures a high success rate in dental implant procedures.

Considerations for International Buyers:

Buyers need to be aware of the differing regulations regarding titanium implants across regions. Understanding local market dynamics, including patient preferences for aesthetics versus functionality, is crucial for successful sales strategies.

Summary Table

| Material | Typical Use Case for zircon dental implants | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Zirconia | Permanent dental implants | Excellent aesthetics and biocompatibility | High manufacturing complexity | High |

| Alumina | Abutments and non-visible restorations | Lower cost and good wear resistance | Brittle and less aesthetic appeal | Medium |

| Composite Resins | Temporary restorations | Versatile and cost-effective | Lower durability and wear resistance | Low |

| Titanium | Load-bearing implants | High strength and biocompatibility | Heavier and less aesthetic appeal | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, helping them make informed decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for zircon dental implants

The manufacturing of zircon dental implants is a complex and precise process that requires adherence to strict quality assurance measures. Understanding these processes is crucial for B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe. Below is a detailed exploration of the typical stages involved in the manufacturing of zircon dental implants, the quality assurance protocols that accompany them, and actionable insights for buyers looking to ensure they partner with reliable suppliers.

Manufacturing Processes

1. Material Preparation

The first step in manufacturing zircon dental implants involves the preparation of zirconia, a biocompatible ceramic material known for its strength and aesthetic qualities. The primary raw material, zirconium dioxide (ZrO2), is sourced from reputable suppliers to ensure purity and consistency.

- Purity Check: Suppliers should provide certificates of analysis (CoA) that confirm the chemical composition of the zirconia.

- Storage Conditions: Proper storage conditions must be maintained to prevent contamination and degradation of the material.

2. Forming

After preparation, the zirconia powder undergoes a forming process. This typically involves either:

- Cold Isostatic Pressing (CIP): This method applies uniform pressure to the zirconia powder, forming it into the desired shape. It is essential for achieving uniform density and minimizing defects.

- Injection Molding: For complex shapes, injection molding may be used, where the zirconia powder is mixed with a binder and injected into molds.

3. Sintering

Once formed, the zirconia undergoes a sintering process, where it is heated to high temperatures (around 1400-1600°C) in a controlled environment. This step is critical for densifying the material and enhancing its mechanical properties.

- Temperature Control: Precise temperature control during sintering is vital to prevent warping or cracking.

- Atmospheric Conditions: The sintering furnace must maintain specific atmospheric conditions to avoid contamination.

4. Assembly and Finishing

After sintering, implants may require additional processes such as:

- Surface Treatment: Techniques like sandblasting or acid etching are used to enhance osseointegration by increasing surface roughness.

- Final Shaping and Polishing: The implants are polished to achieve a smooth surface finish, which is important for aesthetics and functionality.

Quality Assurance

Quality assurance is paramount in the manufacturing of zircon dental implants, ensuring that the final products meet international standards and are safe for patient use.

International Standards

B2B buyers should familiarize themselves with key international quality standards, including:

- ISO 9001: This standard outlines criteria for a quality management system, focusing on consistent product quality and customer satisfaction.

- ISO 13485: Specific to medical devices, this standard emphasizes the need for a comprehensive quality management system throughout the product lifecycle.

Additionally, region-specific certifications may apply:

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Certification: Relevant for suppliers in regions like Africa and the Middle East, ensuring adherence to pharmaceutical standards for medical products.

Quality Control Checkpoints

Quality control processes should include several critical checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to identify and rectify defects early.

- Final Quality Control (FQC): A thorough examination of the finished product, including dimensional checks and surface quality assessments.

Common Testing Methods

Testing methods play a vital role in verifying the quality of zircon dental implants:

- Mechanical Testing: Assessing tensile strength, flexural strength, and fatigue resistance.

- Biocompatibility Testing: Ensuring that the materials used are safe for human use through cytotoxicity and sensitization tests.

- Sterility Testing: Critical for ensuring that the implants are free from microbial contamination before they reach the market.

Verifying Supplier Quality Control

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential to mitigate risks. Here are actionable steps:

-

Conduct Supplier Audits: Regular audits can help assess a supplier’s compliance with quality standards and manufacturing practices. Consider third-party auditors for unbiased assessments.

-

Request Quality Assurance Reports: Suppliers should provide documentation detailing their quality control processes, including test results and compliance certificates.

-

Engage Third-Party Inspectors: Independent inspection agencies can verify the quality of products before they are shipped, ensuring adherence to specified standards.

-

Establish Clear Communication: Maintain open lines of communication with suppliers to address quality concerns promptly and facilitate continuous improvement.

Conclusion

Understanding the manufacturing processes and quality assurance standards for zircon dental implants is crucial for B2B buyers. By focusing on the key stages of production, adherence to international standards, and rigorous quality control measures, buyers can make informed decisions when selecting suppliers. This knowledge not only enhances product reliability but also fosters trust in the partnerships that drive business growth in the competitive dental implant market.

Related Video: How Things Are Made | An Animated Introduction to Manufacturing Processes

Comprehensive Cost and Pricing Analysis for zircon dental implants Sourcing

Understanding the Cost Structure of Zircon Dental Implants

When sourcing zircon dental implants, it’s crucial to grasp the comprehensive cost structure involved. The primary components include:

- Materials: Zirconium oxide is the main material used in these implants, known for its strength and biocompatibility. The quality of zirconium can significantly affect costs; higher purity levels typically lead to higher prices.

- Labor: Skilled labor is required for both the manufacturing and assembly of dental implants. Labor costs can vary widely depending on the region; for instance, countries with higher wage standards may incur greater expenses.

- Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can mitigate overhead costs, allowing for competitive pricing.

- Tooling: The initial setup costs for molds and production tools can be substantial. These costs are often amortized over the production run, influencing the unit cost, especially for smaller orders.

- Quality Control (QC): Rigorous QC processes are essential to ensure the implants meet international standards. The costs associated with testing and certification can be significant, but they are vital for maintaining product quality and safety.

- Logistics: Shipping costs can vary based on the distance and mode of transport. International buyers should consider customs duties and import taxes, which can add to the overall cost.

- Margin: Suppliers typically apply a markup to cover their operational costs and profit margin. Understanding the supplier’s business model can help buyers negotiate better pricing.

Influencers on Pricing for Zircon Dental Implants

Several factors can influence the pricing of zircon dental implants:

- Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should evaluate their purchasing needs against supplier MOQ policies to optimize costs.

- Specifications/Customization: Custom implants or specific designs can increase costs due to additional tooling or materials required. Buyers should clearly define their needs to avoid unexpected charges.

- Quality and Certifications: Implants that meet higher quality standards or possess specific certifications (e.g., ISO, CE marking) may command a premium. It’s essential to balance quality requirements with budget constraints.

- Supplier Factors: The supplier’s reputation, location, and production capabilities can affect pricing. Buyers should conduct thorough due diligence on suppliers to ensure they align with their quality and pricing expectations.

- Incoterms: The terms of shipping can significantly impact total costs. Understanding Incoterms can help buyers manage shipping risks and costs effectively.

Tips for International B2B Buyers

Navigating the complexities of sourcing zircon dental implants requires strategic planning and negotiation skills. Here are actionable tips:

- Negotiate Terms: Leverage your purchasing power to negotiate better terms, such as pricing, lead times, and payment terms. Establishing a long-term relationship can lead to more favorable conditions.

- Focus on Cost-Efficiency: Assess the total cost of ownership, including logistics and potential tariffs. Sometimes, choosing a supplier closer to your market can reduce overall expenses.

- Be Aware of Pricing Nuances: Pricing may fluctuate based on market demand, raw material costs, and currency exchange rates. Keeping abreast of these trends can provide leverage during negotiations.

- Conduct Supplier Evaluations: Regularly assess suppliers for performance, quality, and pricing. This can help identify potential cost-saving opportunities and ensure consistent supply chain reliability.

- Understand Local Regulations: For buyers in regions like Africa and South America, it’s crucial to be aware of local regulations regarding dental products. Compliance can impact both costs and market entry strategies.

Disclaimer

Prices for zircon dental implants can vary widely based on the aforementioned factors and market conditions. The figures presented should be considered indicative and subject to change. Always request formal quotes from suppliers to obtain accurate pricing tailored to your specific needs.

Essential Technical Properties and Trade Terminology for zircon dental implants

Key Technical Properties of Zircon Dental Implants

When considering zircon dental implants, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

-

Material Grade

Zircon dental implants are typically categorized by their material grade, which indicates the quality and composition of the zirconia used. High-grade zirconia, such as Yttria-stabilized tetragonal zirconia polycrystal (Y-TZP), is preferred for its enhanced strength and biocompatibility. For B2B buyers, selecting high-grade materials ensures durability and longevity of the implants, reducing the risk of failure and additional costs associated with replacements. -

Flexural Strength

This property measures the ability of zircon dental implants to withstand bending forces without fracturing. High flexural strength, generally over 1,000 MPa, is vital for implants that will endure substantial chewing forces. B2B buyers should prioritize implants with high flexural strength to enhance patient outcomes and minimize the potential for implant failure. -

Tensile Strength

Tensile strength refers to the maximum stress that a material can withstand while being stretched or pulled before breaking. For zircon dental implants, a tensile strength of at least 900 MPa is desirable. This specification is essential for ensuring that the implants can endure the dynamic forces of the oral environment, which is critical for long-term success. -

Porosity

The porosity of zircon dental implants affects their mechanical properties and biocompatibility. Low porosity is preferred as it minimizes the risk of bacterial colonization and enhances the material’s strength. B2B buyers should ensure that the implants they consider have controlled porosity levels to promote better integration with bone and reduce the likelihood of complications. -

Surface Roughness

This refers to the texture of the implant’s surface, which can influence osseointegration—the process by which the implant fuses with the bone. A roughened surface can enhance the bonding process. Buyers should look for implants with optimized surface roughness to ensure better stability and long-term success in dental applications.

Common Trade Terminology in Zircon Dental Implants

Familiarity with industry jargon can significantly aid B2B buyers in navigating the procurement process. Here are some key terms:

- OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of zircon dental implants, understanding the OEM can provide insights into the quality and reliability of the products being offered.

Illustrative Image (Source: Google Search)

- MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management, particularly when sourcing from international suppliers.

Illustrative Image (Source: Google Search)

-

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. B2B buyers should use RFQs to gather competitive pricing and terms for zircon dental implants, enabling informed decision-making. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery timelines, which are critical for smooth international transactions. -

CE Marking

In Europe, CE marking indicates that a product complies with health, safety, and environmental protection standards. For B2B buyers in Europe, verifying CE marking is crucial for ensuring that zircon dental implants meet regulatory requirements and can be safely marketed. -

Biocompatibility

This term refers to the ability of a material to perform with an appropriate host response when applied in a medical context. For zircon dental implants, biocompatibility is essential for patient safety and acceptance, making it a critical consideration for buyers.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing zircon dental implants, ultimately leading to improved patient outcomes and business success.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the zircon dental implants Sector

Market Overview & Key Trends

The zircon dental implants market is witnessing robust growth, driven by advancements in dental technology and increasing demand for aesthetic and biocompatible solutions. Global drivers include a rising aging population, increasing awareness of dental health, and a shift towards minimally invasive procedures. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly prioritizing high-quality materials that ensure durability and patient satisfaction.

Current sourcing trends indicate a significant move towards digitalization and automation in the manufacturing processes. Technologies such as 3D printing and CAD/CAM systems are becoming prevalent, enabling faster production cycles and custom solutions tailored to specific patient needs. B2B buyers should look for suppliers that leverage these technologies, as they can offer competitive advantages in terms of cost efficiency and product customization.

Emerging markets, particularly in Africa and South America, are expected to see increased investment in dental healthcare infrastructure, providing opportunities for suppliers to establish partnerships. Buyers should also be aware of the importance of regulatory compliance and certifications, as these can greatly influence purchasing decisions in the European market, where stringent guidelines ensure product safety and efficacy.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of business strategy in the zircon dental implants sector. The environmental impact of dental products, including manufacturing waste and resource consumption, necessitates a focus on eco-friendly practices. B2B buyers should seek suppliers who prioritize sustainable sourcing of zirconium and other materials, ensuring that their products are not only high-quality but also environmentally responsible.

The importance of ethical supply chains cannot be overstated. Buyers must consider suppliers that adhere to fair labor practices and demonstrate transparency in their sourcing processes. Certifications such as ISO 14001 (Environmental Management) and those related to responsible mining practices can serve as indicators of a supplier’s commitment to sustainability. Furthermore, the adoption of ‘green’ materials in the production of zircon dental implants is gaining traction, offering alternatives that reduce carbon footprints.

Investing in sustainable products not only aligns with corporate social responsibility goals but can also enhance brand reputation among environmentally conscious consumers. Buyers in Africa, South America, the Middle East, and Europe should engage with suppliers who are at the forefront of these trends, as they are likely to lead the market in innovation and consumer trust.

Brief Evolution/History

Zircon dental implants have evolved significantly over the past few decades. Initially introduced in the late 20th century, zirconium oxide implants quickly gained popularity due to their superior aesthetic qualities and biocompatibility compared to traditional titanium options. Over time, advancements in manufacturing techniques have enhanced the mechanical properties of zircon implants, making them a preferred choice among dental professionals.

As the demand for dental implants continues to rise, the zircon dental implants sector is poised for further innovation. This ongoing evolution emphasizes the importance for B2B buyers to stay informed about the latest developments and trends, ensuring they are sourcing the best possible products for their markets.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of zircon dental implants

-

What criteria should I consider when vetting suppliers of zircon dental implants?

When vetting suppliers, prioritize their experience and reputation in the dental industry. Look for certifications such as ISO 13485 for medical devices and CE marking for compliance with European standards. Assess their production capabilities and technology to ensure they can meet your specifications. Additionally, investigate customer reviews and request references from other international buyers to gauge reliability and quality of service. Engaging suppliers who have a strong history in your target market can also enhance trust. -

Can zircon dental implants be customized to meet specific requirements?

Yes, many suppliers offer customization options for zircon dental implants to cater to unique needs. This can include variations in size, shape, and surface texture. When considering customization, communicate your specifications clearly to the supplier and inquire about their design capabilities. It’s also advisable to request prototypes or samples before placing a bulk order to ensure the product meets your expectations and aligns with local regulatory requirements. -

What are the typical minimum order quantities (MOQ) and lead times for zircon dental implants?

MOQs for zircon dental implants can vary significantly based on the supplier and the complexity of the order. Generally, MOQs may range from 50 to 200 units. Lead times also depend on the supplier’s production capacity and your order size; expect anywhere from 4 to 12 weeks. Always clarify these details upfront to avoid delays in your supply chain. Additionally, consider discussing flexible ordering options for future needs, which can help in inventory management. -

What payment methods are commonly accepted by suppliers of zircon dental implants?

International suppliers typically accept various payment methods, including bank transfers (TT), letters of credit, and sometimes payment platforms like PayPal. When negotiating payment terms, ensure they align with your financial capabilities and risk tolerance. It’s advisable to agree on a payment schedule that may include an upfront deposit followed by balance payments upon delivery or after quality inspection. Always ensure that payment terms are documented in the contract to avoid disputes. -

How can I ensure quality assurance and certifications for zircon dental implants?

To ensure quality, request documentation for all relevant certifications, such as ISO and CE marks, which indicate compliance with international standards. Suppliers should also provide quality control processes, such as batch testing and inspection reports. Consider conducting audits or site visits to their manufacturing facilities if possible. Additionally, ensure that the implants come with a warranty and clear return policies in case the products do not meet the specified standards. -

What logistics considerations should I take into account when importing zircon dental implants?

Logistics is crucial when importing zircon dental implants. Consider the shipping method (air vs. sea), as air freight is faster but more expensive. Factor in customs regulations and import duties specific to your country, as they can impact overall costs. Collaborate with a logistics partner experienced in medical devices to ensure compliance with shipping regulations. Additionally, verify that the supplier can provide necessary documentation for customs clearance to prevent delays. -

How should I handle disputes or issues with suppliers of zircon dental implants?

Having a clear dispute resolution process in your contract is essential. Specify the steps to take in case of disagreements, such as mediation or arbitration, and identify the governing law. Maintain open lines of communication with your supplier to address issues promptly. Document all communications and agreements to provide a clear record if disputes escalate. Building a positive relationship with your supplier can also facilitate smoother resolutions when challenges arise. -

What trends should I be aware of in the zircon dental implants market?

Stay informed about advancements in dental technology, such as digital dentistry and 3D printing, which are reshaping the zircon dental implants landscape. Increased focus on biocompatibility and patient safety is driving demand for high-quality materials. Additionally, monitor regional market growth, particularly in Africa and South America, where dental health initiatives are expanding. Understanding these trends can help you anticipate market demands and align your sourcing strategies accordingly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for zircon dental implants

In conclusion, the strategic sourcing of zircon dental implants presents a significant opportunity for international B2B buyers across Africa, South America, the Middle East, and Europe. Emphasizing quality, reliability, and cost-efficiency can lead to enhanced patient satisfaction and improved clinical outcomes. As the demand for dental implants continues to grow, it is crucial for buyers to develop strong relationships with reputable suppliers who can provide consistent quality and innovation.

Key Takeaways for B2B Buyers:

- Assess Supplier Credentials: Ensure that suppliers adhere to international standards and possess relevant certifications.

- Leverage Local Markets: Explore regional suppliers to reduce shipping costs and lead times, especially in rapidly growing markets like Nigeria and South Africa.

- Invest in Training: Equip your dental professionals with knowledge about zircon implants to enhance service delivery and patient education.

Looking forward, the dental implant market is set to evolve with advancements in technology and material science. Buyers should remain vigilant and adaptable to changes, aligning their sourcing strategies with market trends. By proactively engaging with suppliers and investing in quality solutions, businesses can secure a competitive edge in the dynamic dental landscape. Now is the time to act—reassess your sourcing strategies and position your practice for future growth.