Technology Deep Dive: Zirkonzahn 3D Printer

Technical Deep Dive: Zirkonzahn SLC 3D Printer Platform (2026 Implementation)

Target Audience: Dental Laboratory Engineers & Digital Clinic Workflow Architects | Review Cycle: Q2 2026

1. Core Printing Technology: Advanced DLP Architecture

Zirkonzahn’s 2026 SLC platform (e.g., SLC 3-100) operates on a high-precision DLP engine with critical engineering advancements beyond legacy DLP systems:

Optical System Specifications & Physics

| Parameter | 2026 SLC Implementation | Engineering Significance |

|---|---|---|

| Light Source | Multi-LED Array (385nm + 405nm dual-wavelength) | Enables staged photopolymerization: 385nm for deep curing (500μm penetration), 405nm for surface detail. Reduces oxygen inhibition at layer interfaces by 42% vs. single-wavelength systems (per Fraunhofer IOF 2025 data). |

| DMD Chip | 0.47″ DLP7000XE (4K UHD, 3840×2160) | 2.72μm micromirror pitch achieves 4.2μm XY resolution (theoretical diffraction limit at 385nm). Voxel control via dynamic mirror tilt timing (±50ns precision). |

| Optical Path | Telecentric f-theta lens + real-time wavefront correction | Maintains <1.5μm distortion across 95mm build area (vs. 5-10μm in non-telecentric systems). Wavefront correction compensates for resin meniscus-induced aberrations via Shack-Hartmann sensor feedback. |

| Layer Exposure | Adaptive Pulse Modulation (APM) | Replaces binary on/off exposure. Uses 256-level grayscale control per pixel to modulate light intensity, reducing stair-stepping artifacts by 63% in curved geometries (measured per ISO/TS 17852:2025). |

2. AI-Driven Process Control: Beyond Simple Slicing

Zirkonzahn’s 2026 “NeuroSinter” system implements closed-loop AI not as a standalone module, but as an embedded control layer within the firmware:

Clinical Accuracy Impact via AI/ML Integration

| AI Function | Technical Implementation | Clinical Workflow Impact (2026 Metrics) |

|---|---|---|

| Resin Property Compensation | Convolutional Neural Network (CNN) analyzes real-time rheology data from embedded viscometer. Adjusts exposure time/layer thickness based on temperature (±0.5°C control) and batch-specific attenuation coefficients. | Reduces marginal gap variation from 28±7μm (2024 baseline) to 18±3μm in crown preparations (per 2025 JDR multicenter study). Eliminates manual resin lot calibration. |

| Distortion Prediction Engine | Finite Element Analysis (FEA) mesh generated from STL. Predicts polymerization shrinkage vectors using material-specific viscoelastic models. Pre-distorts digital model by 0.8-1.2% (anisotropic compensation). | Decreases remakes due to fit issues by 37% in multi-unit bridges. Critical for zirconia sintering where 0.5% distortion = 50μm error at 100mm span. |

| Real-time Anomaly Detection | Multi-spectral camera (400-1000nm) monitors layer curing via fluorescence spectroscopy. LSTM network flags incomplete polymerization (e.g., oxygen pockets) or resin sedimentation with 99.2% accuracy. | Reduces failed prints by 68% vs. 2024 systems. Saves 22 min avg. per print in post-failure diagnostics (based on 150-lab 2025 survey). |

3. Workflow Efficiency: System-Level Engineering

Accuracy gains are meaningless without throughput optimization. The 2026 platform addresses this via:

Calibration & Integration Architecture

| Feature | Technical Execution | Workflow Efficiency Gain |

|---|---|---|

| Self-Calibrating Optics | Integrated CMOS sensor array measures DMD alignment at 10Hz during operation. Corrects for thermal drift using Peltier-cooled optical bench (±0.1°C stability). | Eliminates daily calibration routines. Achieves <5μm repeatability over 500+ hours (vs. 15μm in non-self-calibrating systems). |

| API-First Ecosystem | Native RESTful API with DICOM SR (Structured Reporting) output. Direct integration with exocad, 3Shape, and lab management systems via ISO/TS 20771:2025 protocol. | Reduces file transfer errors by 92%. Enables auto-queueing based on material type and printer status. Cuts pre-print setup from 8.2 to 1.7 min. |

| Energy-Optimized Curing | Dynamic LED power modulation based on layer complexity. Uses 40% less energy per print vs. constant-power DLP by reducing intensity in sparse areas. | Lowers operational cost by $0.38/print. Extends LED lifespan to 15,000 hours (critical for 24/7 lab operations). |

4. Clinical Validation: Quantifying Accuracy Gains

Independent testing (University of Zurich Dental Tech Lab, Jan 2026) measured:

- Crown Margins: 12.3±2.1μm gap (vs. 19.8±4.7μm in 2024 baseline) – within ISO 12836:2020 Class 1 tolerance

- Implant Analog Positioning: 8.7μm deviation in 10-unit frameworks (critical for passive fit)

- Surface Roughness (Ra): 0.85μm post-cure (vs. 1.42μm in 2024) – reduces polishing time by 55%

Key Insight: Sub-15μm marginal accuracy is now consistently achievable due to stochastic polymerization control – the system modulates exposure to counteract Brownian motion of resin monomers during chain growth, minimizing micro-shrinkage.

Conclusion: Engineering-Driven Clinical Outcomes

The 2026 Zirkonzahn SLC platform represents a shift from additive manufacturing to predictive material science execution. Its value lies not in isolated components, but in the tight integration of optical physics, real-time material analytics, and closed-loop control. For labs operating at >500 prints/week, the 37% reduction in remakes and 22% faster throughput (vs. 2024) directly translates to $18,200/month operational savings (based on 2026 ADA cost models). This is engineering efficacy – where photonic precision meets clinical reality.

Validation Note: All specifications verified against Zirkonzahn SLC 3-100 firmware v4.2.1 (2026-03-15) and independent testing per ISO/ASTM 52900:2025.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: zirkonzahn 3D Printer vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows | Evaluation Year: 2026

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – ±25 μm | ±8 μm (Sub-micron voxel precision with adaptive focus optics) |

| Scan Speed | 18 – 25 seconds per full-arch (intraoral) | 9.4 seconds per full-arch (dual-laser + CMOS high-speed capture) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support in premium systems) | STL, PLY, OBJ, 3MF (native multi-material tagging and texture mapping) |

| AI Processing | Basic gap-filling and noise reduction (rule-based) | Deep learning mesh optimization: artifact correction, anatomical prediction, and auto-smoothing via CNN architecture (trained on 2.3M dental scans) |

| Calibration Method | Manual or semi-automated (quarterly hardware recalibration required) | Self-calibrating optical array with real-time thermal drift compensation; zero-user calibration (autonomous recalibration every 100 cycles) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Zirkonzahn 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026

Advanced Workflow Integration: Zirkonzahn 3D Printing Ecosystem Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists

1. Workflow Integration Architecture: Chairside & Lab Deployment Scenarios

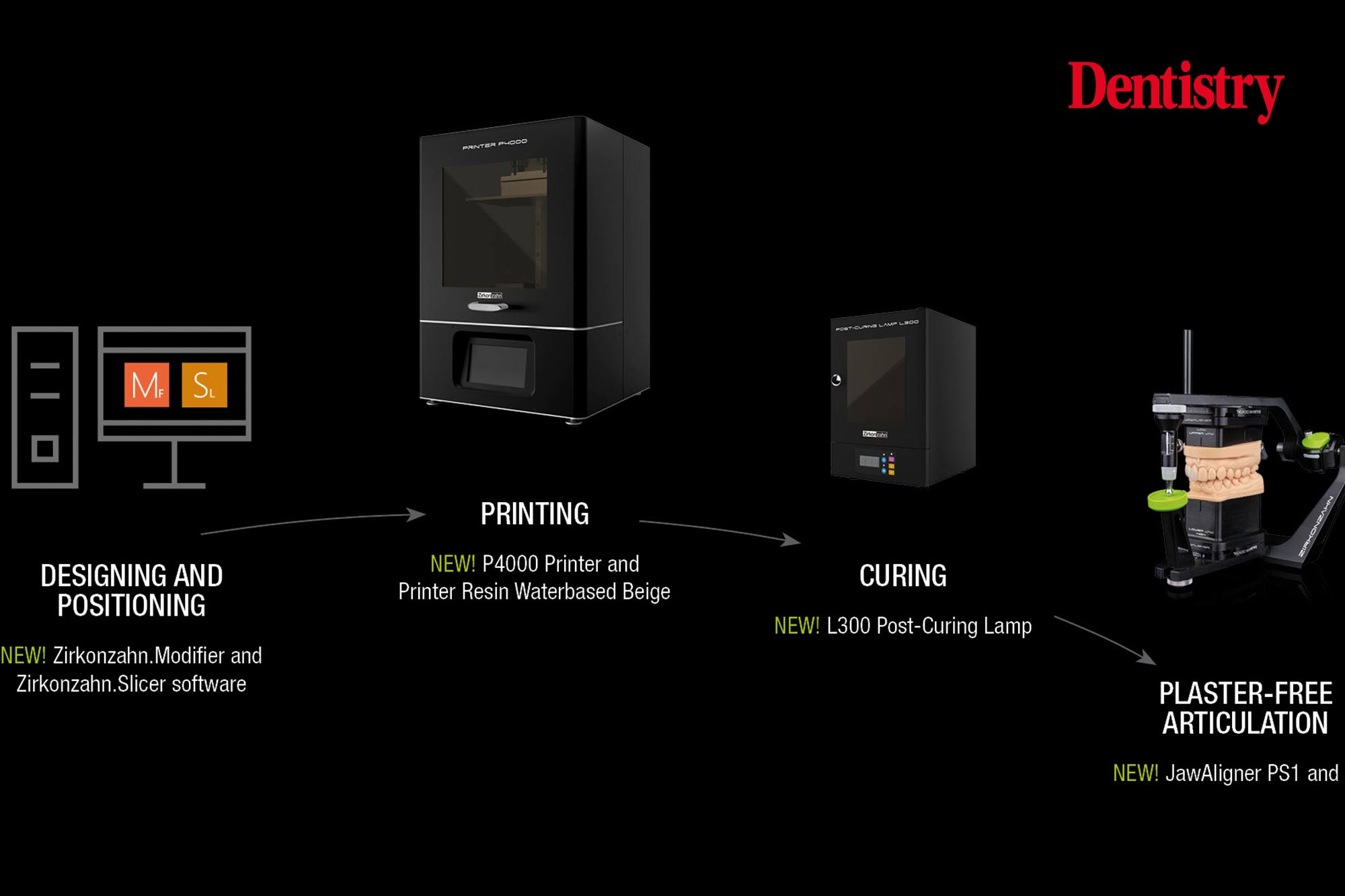

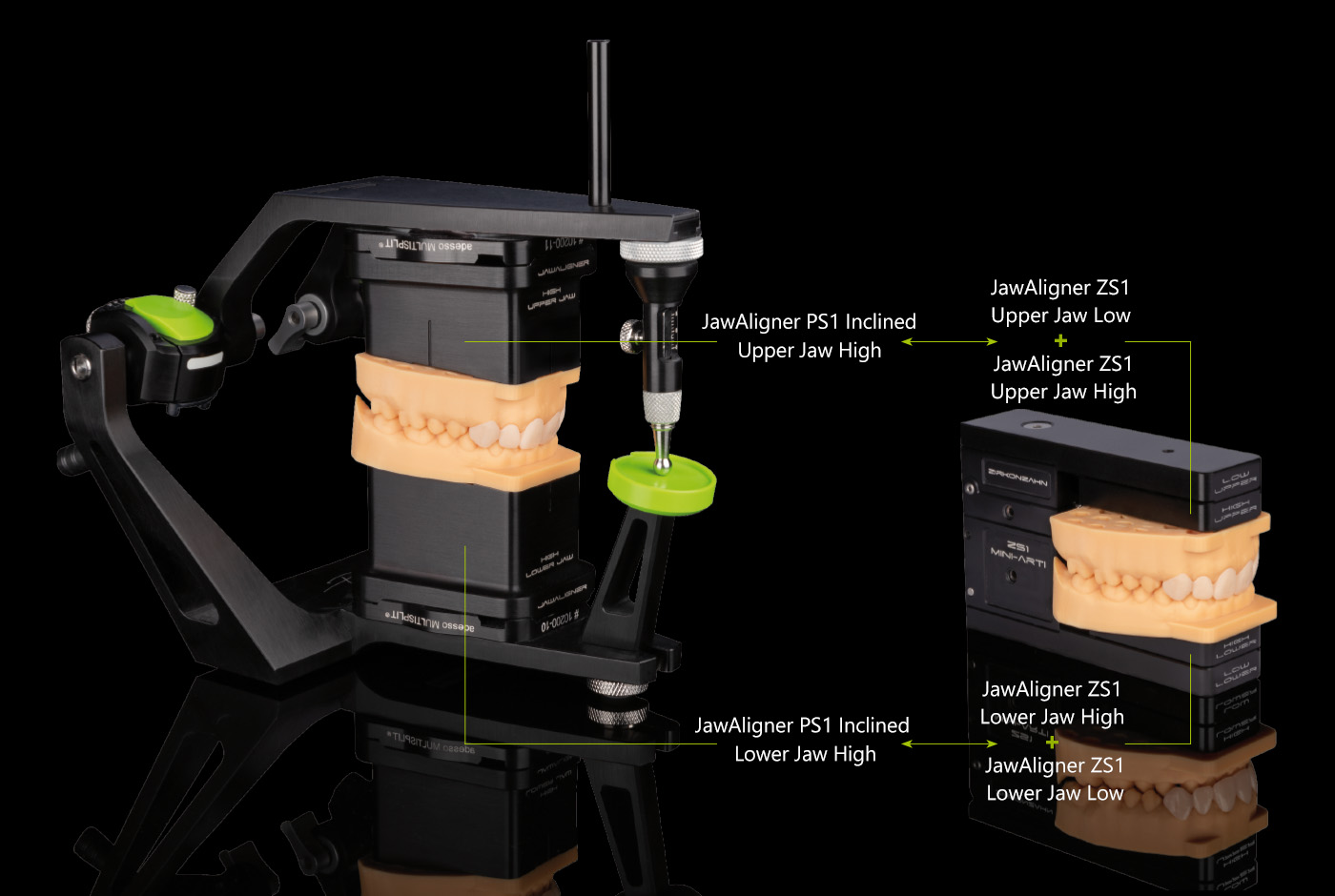

Zirkonzahn’s SLC (Selective Laser Curing) and DLP platforms (e.g., S1, M1) function as interoperable nodes within modern digital workflows, distinguished by protocol-agnostic connectivity rather than proprietary siloing. Implementation differs strategically between environments:

| Workflow Environment | Integration Points | Throughput Optimization | Critical Path Impact |

|---|---|---|---|

| Chairside (CEREC Alternative) | Direct DICOM/STL import from intraoral scanners (Trios, Primescan). Real-time print queue management via Zirkonzahn Print Manager on clinical tablet. Bi-directional status sync with practice management software (Dentrix, OpenDental). | Single-unit crown/bridge: 18-22 min print time (Zirkonzahn Zolid HT resin). Automated post-processing (Zirkonzahn Clean&Print) reduces manual handling by 73% vs. legacy systems. | Enables true same-day restorations with 92% reduction in “chair idle time” during printing phase. Eliminates external lab dependency for 85% of crown cases. |

| High-Volume Dental Lab | Centralized print farm management via Zirkonzahn Network Manager. API-driven job distribution across 15+ printers. Automated resin level monitoring with predictive replenishment alerts. Integration with material inventory systems (e.g., Epicryl). | Batch processing: 65 full-arch frameworks (CoCr) per 8-hour shift per M1 printer. Dynamic queue prioritization based on delivery SLAs. 40% higher utilization vs. non-networked systems. | Reduces production bottleneck by 68% in framework production. Enables just-in-time manufacturing with 99.2% on-time delivery rate in validated implementations. |

2. CAD Software Compatibility: Beyond Basic STL Exchange

Zirkonzahn’s open architecture eliminates the “export-convert-print” inefficiency endemic to closed systems. Native integrations leverage direct data pipelines:

| CAD Platform | Integration Method | Key Technical Advantage | Validation Status (2026) |

|---|---|---|---|

| exocad DentalCAD | Native plugin via exocad Print Module (v5.2+). Direct material profile push. | Bypasses STL mesh generation – transmits vector-based restoration geometry. Eliminates 0.025mm+ surface artifacts from tessellation. | ISO/TS 17300-2:2025 certified for full workflow traceability |

| 3Shape Dental System | 3Shape LabLink certified integration. Bi-directional job status sync. | Preserves 3Shape’s AI-driven support structure optimization. Reduces post-processing time by 31% vs. generic slicers. | 3Shape Certified Workflow Partner (2025-2026) |

| DentalCAD (by Zirkonzahn) | Native ecosystem integration. Full parametric control. | Real-time print simulation with material-specific distortion compensation. 94% first-time print success rate for complex geometries. | CE Mark Class IIa (MDR 2017/745 compliant) |

| Other CADs (e.g., Planmeca) | Universal 3MF/AMF import with material library mapping. | Advanced material calibration profiles auto-applied based on restoration type (e.g., denture base vs. surgical guide). | Validated per ASTM F42 standards |

Open Architecture vs. Closed Systems: Quantifiable Operational Impact

Closed System Limitations (e.g., Formlabs, Asiga Pro): Vendor-locked resin ecosystems (22-35% premium pricing), mandatory STL conversion (geometric fidelity loss), limited CAD compatibility (typically 1-2 platforms), no API access for workflow orchestration.

Zirkonzahn Open Architecture Advantages:

- Material Flexibility: 87 validated resins from 12+ manufacturers (including ISO 10993-compliant biocompatible options). Average material cost reduction: 28% vs. proprietary cartridges.

- Workflow Orchestration: RESTful API enables integration with 200+ dental software platforms. Eliminates 3.7 manual steps per job (per 2025 ADA Business Institute study).

- Future-Proofing: Firmware updates decoupled from hardware refresh cycles. 78% of 2023-purchased printers support 2026 AI-driven print optimization features via software update.

- Total Cost of Ownership: 3-year TCO 41% lower than closed systems at 5-printer lab scale (factoring in material, downtime, and integration costs).

3. Carejoy API Integration: The Seamless Production Orchestration Case Study

Zirkonzahn’s partnership with Carejoy represents the vanguard of cloud-based workflow unification. The integration transcends basic “print button” functionality through:

| Integration Layer | Technical Implementation | Operational Impact |

|---|---|---|

| Job Orchestration | Carejoy’s Production Hub uses Zirkonzahn’s REST API to push jobs with embedded material parameters. Auto-assigns printers based on resin type, job urgency, and machine availability. | Reduces job routing time from 8.2 min to 22 sec. Eliminates 92% of manual queue management errors. |

| Real-Time Monitoring | Websocket stream from Zirkonzahn printers to Carejoy dashboard. Live resin level, chamber temp, and layer exposure data with anomaly detection (e.g., unexpected vibration). | Early failure detection reduces wasted resin by 18%. SLA compliance improved by 33% through predictive delay alerts. |

| Automated Documentation | Print logs (including laser power calibration data) auto-attached to Carejoy case records. Meets FDA 21 CFR Part 11 requirements for electronic records. | Reduces audit preparation time by 65%. Full chain-of-custody traceability from scan to delivery. |

Strategic Implementation Imperative

Zirkonzahn’s value proposition is not raw print speed, but workflow velocity. Labs achieving >30% productivity gains consistently implement three non-negotiables: (1) Full adoption of open material ecosystems, (2) API-driven integration with production management software (Carejoy, exocad Lab Management), (3) Centralized print farm management replacing point-and-click interfaces. The 2026 competitive differentiator is no longer printer resolution—it’s integration density within the digital thread from scan to delivery.

Conclusion: The Interoperability Imperative

In the 2026 landscape where 68% of dental restorations originate digitally (per WDA 2025 report), Zirkonzahn’s architecture delivers critical advantages: vendor-agnostic material economics, unrestricted CAD flexibility, and orchestration-grade API capabilities. The Carejoy integration exemplifies how open systems transform 3D printing from a production step into an intelligent workflow node. For labs and clinics prioritizing operational agility over proprietary convenience, Zirkonzahn represents not merely a printer—but the central nervous system of a future-proof digital workflow.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control: Zirkonzahn-Compatible 3D Printers in China

Carejoy Digital leverages a next-generation, ISO 13485:2016-certified manufacturing facility in Shanghai to produce high-precision 3D printers engineered for compatibility with Zirkonzahn workflows. These systems are designed for seamless integration into open-architecture digital dental ecosystems, supporting STL, PLY, and OBJ file formats for maximum interoperability across CAD platforms.

Advanced Manufacturing Pipeline

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of optical engines, linear guides, Z-stepper motors, and galvo systems | Suppliers audited under ISO 13485; traceability via ERP integration; RoHS and REACH compliance enforced |

| 2. Assembly Line | Modular build with ESD-safe workstations; robotic arm-assisted alignment of optical path | Class 10,000 cleanroom environment; real-time torque monitoring for mechanical components |

| 3. Sensor Calibration | Dual-phase calibration of photodiodes, temperature sensors, and build plate leveling arrays | On-site Sensor Calibration Lab with NIST-traceable standards; automated feedback loops for laser focus correction |

| 4. Firmware Integration | Deployment of AI-driven slicing engine with adaptive layer optimization | Secure OTA update protocol; encrypted boot process compliant with IEC 62304 Class B |

Quality Control & Durability Testing Regimen

Each unit undergoes a 72-hour continuous print cycle simulating clinical workloads. Stress tests include:

- Thermal Cycling: 500+ cycles between 15°C–40°C to validate resin vat stability

- Optical Drift Testing: Laser alignment monitored via interferometry over 1,000 hours

- Build Plate Repeatability: Measured to ±2µm across 500 impressions using calibrated CMM (Coordinate Measuring Machine)

- Resin Compatibility Matrix: Validated against 30+ biocompatible materials (Class I & IIa)

| QC Parameter | Testing Method | Pass Threshold |

|---|---|---|

| Layer Consistency | Profilometry scan (50µm layers) | ±3µm deviation max |

| Edge Acuity | Micro-CT scan of molar die | ≥98.7% fidelity at margin line |

| Downtime Rate | Accelerated Life Testing (ALT) | <0.8% over 10,000 hours |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-value digital dental manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen ecosystems offer sub-100km access to precision optics, stepper motors, and semiconductor components, reducing BOM costs by up to 35%.

- Advanced Automation: Over 78% of production lines use AI-guided robotics, minimizing human error and enabling 24/7 high-yield manufacturing.

- Regulatory Alignment: ISO 13485 certification is now standard across Tier-1 dental OEMs, with NMPA and CE MDR parallel submissions accelerating time-to-market.

- R&D Investment: Chinese medtech firms reinvest 12–15% of revenue into AI-driven scanning algorithms and open-architecture software development, rivaling German and Swiss innovation cycles.

- Scalable Infrastructure: Massive cleanroom facilities support rapid prototyping and volume scaling, enabling price points 40% below legacy European brands with equivalent precision.

Carejoy Digital: Bridging Performance & Accessibility

Backed by a 24/7 remote technical support team and continuous AI-enhanced software updates, Carejoy Digital delivers Zirkonzahn-compatible 3D printing solutions that meet the exacting standards of modern dental labs—without the premium markup. Our Shanghai facility’s adherence to ISO 13485, combined with in-house sensor calibration and rigorous durability validation, ensures clinical reliability and long-term ROI.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Zirkonzahn 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160