Introduction: Navigating the Global Market for 3d dental implants

The global market for 3D dental implants is rapidly evolving, driven by advancements in technology and an increasing demand for high-quality dental solutions. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding this market is crucial for making informed sourcing decisions. 3D dental implants not only enhance patient outcomes through precision and customization but also represent a significant opportunity for businesses to offer cutting-edge solutions that meet the diverse needs of dental practitioners worldwide.

This comprehensive guide will delve into essential aspects of 3D dental implants, including types, materials, manufacturing processes, quality control measures, and an overview of key suppliers. Buyers will also gain insights into cost structures and current market trends, enabling them to navigate the complexities of sourcing these innovative products.

By exploring frequently asked questions, this guide aims to empower B2B buyers with the knowledge necessary to evaluate suppliers effectively and select products that align with their operational goals. Whether you are a dental clinic in Kenya seeking reliable implant solutions or a distributor in Mexico looking to expand your product line, this resource will equip you with actionable insights to thrive in the competitive landscape of dental technology. Embrace the future of dental care with confidence, armed with the information you need to make strategic purchasing decisions.

Understanding 3d dental implants Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Titanium Implants | High strength, biocompatibility, and corrosion resistance | General dentistry, oral surgery | Pros: Durable, widely used; Cons: Higher cost than other materials. |

| Zirconia Implants | Aesthetic appeal, metal-free, and biocompatible | Cosmetic dentistry, implantology | Pros: Excellent aesthetics; Cons: Less proven long-term data. |

| Mini Implants | Smaller diameter, less invasive | Temporary restorations, orthodontics | Pros: Easier placement; Cons: Limited load-bearing capacity. |

| 3D-Printed Implants | Customizable, rapid production | Personalized dental solutions | Pros: Tailored fit; Cons: May require advanced technology and training. |

| Immediate Load Implants | Designed for immediate placement and function | Same-day dental procedures | Pros: Quick patient turnaround; Cons: Requires precise placement skills. |

Titanium Implants

Titanium implants are the gold standard in dental implantology, known for their exceptional strength and biocompatibility. They are suitable for a wide range of applications, from general dentistry to complex oral surgeries. When considering titanium implants, B2B buyers should evaluate supplier certifications and the material’s source to ensure quality and reliability. While they are durable, the higher cost may be a consideration for practices focused on budget management.

Illustrative Image (Source: Google Search)

Zirconia Implants

Zirconia implants are increasingly popular due to their aesthetic properties and metal-free composition, making them ideal for cosmetic dentistry. They are particularly suitable for patients with metal allergies or those seeking a more natural appearance. B2B buyers should assess the long-term performance data of zirconia implants, as they are relatively newer in the market. While they offer excellent aesthetics, the limited clinical history may raise concerns for some practitioners.

Mini Implants

Mini implants are characterized by their smaller diameter, making them less invasive and easier to place. They are particularly useful for temporary restorations and in orthodontic applications. B2B buyers should consider the specific patient demographics their practices serve, as mini implants may be ideal for patients with limited bone density. However, their load-bearing capacity is less than that of traditional implants, which can limit their use in more demanding situations.

3D-Printed Implants

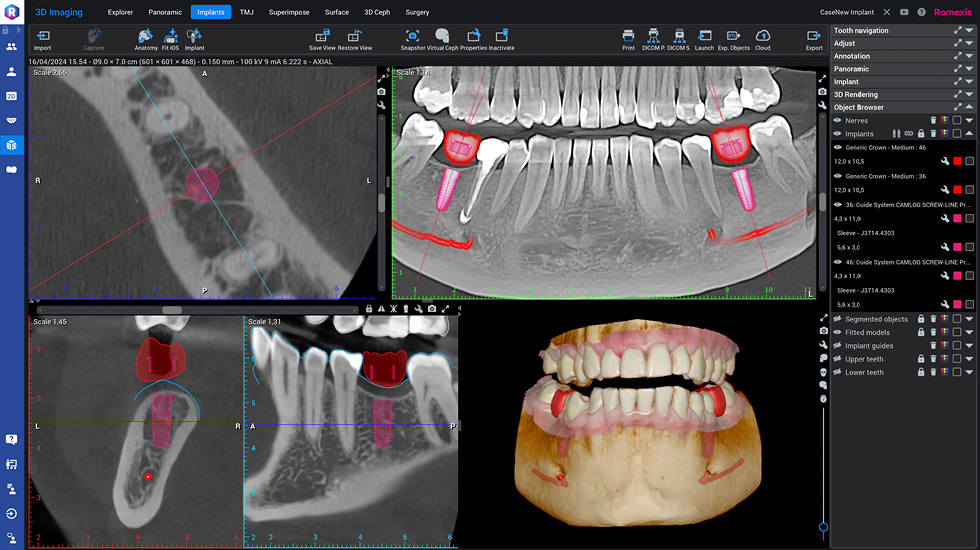

3D-printed implants represent a significant advancement in dental technology, allowing for highly customizable solutions tailored to individual patient needs. This innovation is particularly beneficial in personalized dental applications, where precision is critical. B2B buyers should evaluate the technological capabilities of their suppliers, as 3D printing requires specialized equipment and expertise. While offering a tailored fit, the investment in technology and training can be a barrier for some practices.

Immediate Load Implants

Immediate load implants are designed to be placed and used on the same day, providing significant advantages for patient convenience and satisfaction. These implants are ideal for same-day dental procedures, allowing practices to offer rapid solutions. B2B buyers should consider the skill level of their dental teams, as the success of immediate load implants hinges on precise placement. While they enhance patient turnaround, the need for advanced techniques can pose challenges for less experienced practitioners.

Related Video: DENTAL IMPLANTS : TYPES, SURFACE TREATMENTS, why TITANIUM is used for making implants?

Key Industrial Applications of 3d dental implants

| Industry/Sector | Specific Application of 3D Dental Implants | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Customized dental implants for patients with unique anatomical needs | Improved patient satisfaction and treatment outcomes | Supplier reliability, customization options, and certifications |

| Dental Laboratories | Rapid prototyping of implant designs for testing and production | Reduced time to market and increased innovation | Material quality, technology compatibility, and cost efficiency |

| Oral Surgery Centers | Surgical guides created from 3D-printed implants | Enhanced precision in surgeries, leading to fewer complications | Availability of advanced imaging technologies and training |

| Dental Equipment Suppliers | Development of integrated 3D printing solutions for dental practices | Streamlined operations and cost reduction | Technical support, scalability, and maintenance services |

| Academic Institutions | Research and development of new implant materials and designs | Advancement of dental science and potential new revenue streams | Collaboration opportunities, access to cutting-edge technology, and funding |

Detailed Applications

Dental Clinics

In dental clinics, 3D dental implants are revolutionizing patient care by providing customized solutions tailored to individual anatomical needs. This personalization enhances patient satisfaction and treatment outcomes, as implants are designed to fit seamlessly. International buyers should focus on sourcing from suppliers that offer reliable customization options and possess the necessary certifications to ensure quality and safety standards are met.

Dental Laboratories

Dental laboratories leverage 3D dental implants for rapid prototyping, allowing for quick iterations of implant designs. This capability not only accelerates the development process but also fosters innovation in implant technology. For B2B buyers in this sector, key sourcing considerations include ensuring high material quality, compatibility with existing technologies, and overall cost efficiency to maximize profit margins.

Oral Surgery Centers

In oral surgery centers, 3D-printed surgical guides derived from dental implants enhance the precision of surgical procedures. These guides help surgeons navigate complex anatomical structures, ultimately reducing the risk of complications and improving patient outcomes. Buyers in this field should prioritize suppliers that provide advanced imaging technologies and comprehensive training for the effective use of these innovative solutions.

Dental Equipment Suppliers

Dental equipment suppliers are increasingly integrating 3D printing solutions into their product offerings, enabling practices to streamline operations and reduce costs. By offering comprehensive solutions that include both the printing technology and the dental implants, suppliers can meet the growing demand for efficiency in dental practices. Buyers should seek partners that provide robust technical support, scalable solutions, and ongoing maintenance services to ensure operational continuity.

Academic Institutions

In academic settings, 3D dental implants play a crucial role in research and development, particularly in exploring new materials and designs. Collaborations with industry can lead to advancements in dental science, which may also open up new revenue streams through patents and innovations. Institutions should consider partnerships that grant access to cutting-edge technology and funding opportunities to support their research initiatives.

Related Video: How to Perform Dental Implants by MIS -Tutorial (3D Dental Animation)

Strategic Material Selection Guide for 3d dental implants

When selecting materials for 3D dental implants, international B2B buyers must consider several factors that impact performance, cost, and regulatory compliance. Here, we analyze four common materials used in the production of 3D dental implants: Titanium, Zirconia, PEEK (Polyether Ether Ketone), and Stainless Steel. Each material has unique properties and implications for application, particularly relevant to buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

Titanium

Key Properties: Titanium is renowned for its excellent strength-to-weight ratio, high corrosion resistance, and biocompatibility, making it ideal for dental implants. It can withstand significant mechanical stress and has a high melting point, which is crucial during the manufacturing process.

Pros & Cons: Titanium implants are durable and resistant to wear, which enhances their longevity in dental applications. However, they tend to be more expensive than other materials, and the manufacturing process can be complex due to the need for specialized equipment. Additionally, while titanium is biocompatible, some patients may experience allergic reactions.

Impact on Application: Titanium is compatible with various media, including saline and other bodily fluids, which is essential for dental implants. Its ability to osseointegrate effectively with bone tissue makes it a preferred choice for dental professionals.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM F136 for titanium alloys. In regions like Kenya and Mexico, understanding local regulations regarding medical devices is critical for market entry.

Zirconia

Key Properties: Zirconia is a ceramic material known for its aesthetic appeal and high strength. It offers excellent wear resistance and is less prone to corrosion compared to metals.

Pros & Cons: The primary advantage of zirconia is its tooth-like appearance, making it a popular choice for aesthetic dental implants. However, it is less durable than titanium and can be more brittle, increasing the risk of fracture under excessive stress. The manufacturing process for zirconia can also be more complex and time-consuming.

Impact on Application: Zirconia is suitable for applications requiring high aesthetic value, such as anterior teeth implants. Its compatibility with oral environments makes it a viable option, but its brittleness can limit its use in posterior applications.

Considerations for International Buyers: Compliance with standards like ISO 6872 is essential for zirconia products. Buyers in Europe should be aware of the stringent CE marking requirements for dental materials.

PEEK (Polyether Ether Ketone)

Key Properties: PEEK is a high-performance polymer with excellent mechanical properties and biocompatibility. It is lightweight and resistant to high temperatures and chemical degradation.

Pros & Cons: PEEK’s flexibility and strength make it suitable for various dental applications, including implant abutments. However, it is generally less bioactive than titanium, which may affect osseointegration. The cost of PEEK can also be relatively high compared to traditional materials.

Impact on Application: PEEK is particularly advantageous in applications requiring a combination of strength and flexibility. It is compatible with imaging techniques, which can be beneficial for monitoring implant success.

Considerations for International Buyers: Buyers should consider compliance with ASTM F2026 for PEEK materials. In regions like South America, understanding local market acceptance of polymer-based implants is crucial.

Stainless Steel

Key Properties: Stainless steel is known for its strength, corrosion resistance, and cost-effectiveness. It has a lower melting point compared to titanium, making it easier to manufacture.

Pros & Cons: The main advantage of stainless steel is its affordability and availability. However, it is less biocompatible than titanium and zirconia, which can lead to issues such as corrosion in the oral environment. Additionally, its aesthetic appeal is limited compared to ceramic options.

Impact on Application: Stainless steel is often used in temporary implants or in situations where cost is a significant concern. Its durability makes it suitable for certain applications, but its limitations in biocompatibility may restrict its use in permanent implants.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM F138 for stainless steel. In regions like the Middle East, understanding the regulatory landscape for dental materials is essential for successful market penetration.

Summary Table

| Material | Typical Use Case for 3D Dental Implants | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Permanent dental implants | Excellent biocompatibility | Higher cost, complex manufacturing | High |

| Zirconia | Aesthetic anterior implants | Superior aesthetics | Brittle, less durable | Medium |

| PEEK | Implant abutments | Lightweight, flexible | Less bioactive, high cost | High |

| Stainless Steel | Temporary implants | Cost-effective | Poor biocompatibility, aesthetic limitations | Low |

This guide provides a strategic overview for B2B buyers looking to make informed decisions regarding material selection for 3D dental implants, emphasizing the importance of understanding both technical properties and market-specific considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 3d dental implants

3D dental implants have revolutionized the field of dentistry, offering a more precise and efficient solution for dental restoration. For B2B buyers, understanding the manufacturing processes and quality assurance protocols is crucial to ensure product reliability and compliance with international standards. This section delves into the typical manufacturing stages, key techniques involved, and the quality control measures that are essential for 3D dental implants.

Manufacturing Processes

The manufacturing of 3D dental implants involves several critical stages that ensure the final product meets the required specifications and standards.

1. Material Preparation

Material preparation is the first step in the manufacturing process. This involves selecting appropriate biocompatible materials, such as titanium or zirconia, which are commonly used due to their strength and resistance to corrosion. The materials are then processed to ensure they meet purity and quality standards.

- Actionable Insight: B2B buyers should inquire about the sourcing of materials and any certifications that validate their biocompatibility and safety.

2. Forming

The forming stage typically employs advanced techniques such as Selective Laser Sintering (SLS) or Stereolithography (SLA). These additive manufacturing methods allow for the creation of complex geometries that are tailored to individual patient needs.

- Selective Laser Sintering (SLS): This technique uses a laser to fuse powdered materials, creating a solid structure layer by layer.

-

Stereolithography (SLA): This method uses a UV laser to cure liquid resin into solid parts, known for its high precision.

-

Actionable Insight: Buyers should request detailed information about the forming technology used by suppliers and assess their capability to customize implants based on specific clinical requirements.

3. Assembly

Once the individual components are formed, they undergo an assembly process where various parts of the implant are combined. This may include attaching abutments and other components that ensure the implant functions correctly within the dental structure.

- Actionable Insight: B2B buyers should verify the assembly techniques employed by suppliers, as improper assembly can lead to failures in the implant’s performance.

4. Finishing

Finishing is the final stage of manufacturing, which involves surface treatments to enhance the implant’s properties, such as improving osseointegration (the process by which the implant anchors to the jawbone). This may include methods like sandblasting or acid etching to create a rough surface texture.

- Actionable Insight: Buyers should ask for information on finishing processes, as these can significantly affect the implant’s success rate and longevity.

Quality Assurance

Quality assurance is a critical component in the manufacturing of 3D dental implants. It ensures that products meet the required standards and perform reliably in clinical applications.

International Standards

Several international standards govern the manufacturing and quality assurance processes for dental implants. Key standards include:

- ISO 9001: This is a general quality management standard that ensures organizations meet customer and regulatory requirements consistently.

- ISO 13485: This standard specifically addresses quality management systems for medical devices, including dental implants.

-

CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

-

Actionable Insight: Buyers should ensure that their suppliers are compliant with these standards and can provide documentation to prove certification.

Quality Control Checkpoints

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): This involves monitoring the manufacturing process to identify and rectify any deviations from standards in real-time.

-

Final Quality Control (FQC): This stage includes comprehensive testing of the finished product before it is released for sale.

-

Actionable Insight: B2B buyers should request detailed QC reports that outline the procedures followed at each checkpoint and any corrective actions taken during production.

Common Testing Methods

Testing methods for 3D dental implants can include:

- Mechanical Testing: Assessing the strength and durability of the implants under load.

- Biocompatibility Testing: Ensuring that the materials used do not elicit an adverse reaction in the body.

-

Sterility Testing: Verifying that implants are free from microbial contamination.

-

Actionable Insight: Buyers should inquire about the specific testing protocols used by suppliers and request access to testing results and certificates.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control processes is vital for risk management. Here are some practical steps:

- Conduct Audits: Regular audits of suppliers can help ensure compliance with quality standards. Buyers should have a checklist based on relevant standards like ISO 9001 and ISO 13485.

- Request Quality Reports: Suppliers should be able to provide detailed reports on their QC processes, including any deviations and corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control practices.

Conclusion

Understanding the manufacturing processes and quality assurance measures for 3D dental implants is crucial for B2B buyers, particularly in diverse regions such as Africa, South America, the Middle East, and Europe. By focusing on material selection, forming techniques, assembly methods, and rigorous quality control, buyers can ensure they partner with reliable suppliers who meet international standards. This proactive approach not only mitigates risks but also enhances the overall success of dental restoration projects.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for 3d dental implants Sourcing

When sourcing 3D dental implants, understanding the comprehensive cost structure is crucial for international B2B buyers. The pricing of these implants is influenced by various components that must be carefully analyzed to ensure effective budgeting and procurement strategies.

Cost Components

-

Materials: The choice of materials significantly impacts cost. Titanium and zirconia are common for dental implants, with titanium generally being less expensive. The quality and sourcing of these materials also affect pricing; suppliers with certifications may charge a premium.

-

Labor: Labor costs can vary dramatically based on the region of production. Countries with lower labor costs may offer competitive pricing, but this may come at the expense of quality. It’s essential to evaluate the skill level of the workforce involved in manufacturing 3D dental implants.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. Higher overhead can lead to increased prices. Buyers should inquire about the manufacturing processes and facilities of potential suppliers to gauge overhead implications.

-

Tooling: The initial investment in tooling for 3D printing technology can be substantial. However, once established, the cost per unit decreases significantly. Buyers should consider whether the supplier has the latest technology and how that impacts the pricing structure.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with international standards, which can drive up costs. Suppliers with ISO certifications or similar credentials may command higher prices but provide assurance of quality.

Illustrative Image (Source: Google Search)

-

Logistics: Shipping and handling costs are critical, particularly for international transactions. Factors such as distance, mode of transport, and customs duties can add significant costs. Incoterms will also dictate who bears these costs, affecting the final price.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on their market positioning and competition. Understanding the typical margins in the industry can help buyers negotiate better.

Price Influencers

-

Volume/MOQ: The volume of the order often dictates pricing. Higher quantities typically lead to lower per-unit costs, making it essential for buyers to assess their needs accurately.

-

Specifications/Customization: Custom designs or specialized specifications can increase costs. Buyers should be clear about their requirements upfront to avoid unexpected expenses.

-

Quality/Certifications: Implants that meet higher quality standards or possess certifications may be priced higher. However, this can lead to long-term cost savings through reduced failure rates.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record but can also mitigate risks associated with quality and delivery.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is essential, as it affects the total landed cost. Buyers should clarify responsibilities regarding transport and insurance before finalizing contracts.

Buyer Tips

-

Negotiation: Leverage volume purchases and long-term contracts to negotiate better prices. Establishing a good relationship with suppliers can lead to favorable terms.

-

Cost-Efficiency: Consider not just the purchase price but the Total Cost of Ownership (TCO), which includes maintenance, potential failure costs, and logistics.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and economic conditions in the supplier’s country, which may affect pricing. Engage in thorough market research to understand local pricing trends.

-

Regional Considerations: For buyers from Africa, South America, the Middle East, and Europe, understanding local regulatory requirements and import duties is vital to avoid unexpected costs.

Disclaimer

Prices for 3D dental implants can vary widely based on the factors discussed. This analysis serves as a guideline, and potential buyers should conduct their own due diligence when assessing costs and suppliers.

Spotlight on Potential 3d dental implants Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘3d dental implants’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 3d dental implants

When navigating the complex landscape of 3D dental implants, understanding the essential technical properties and trade terminology is crucial for making informed purchasing decisions. This section outlines key specifications and industry jargon to empower international B2B buyers, especially from Africa, South America, the Middle East, and Europe.

Critical Technical Properties

-

Material Grade

– Definition: This refers to the quality and classification of materials used in 3D dental implants, commonly titanium, zirconia, or cobalt-chromium alloys.

– B2B Importance: Higher-grade materials offer improved biocompatibility and durability, which are vital for long-term patient outcomes. Buyers should prioritize suppliers who adhere to international standards (e.g., ISO 13485) to ensure product reliability. -

Tolerance

– Definition: Tolerance indicates the permissible limit of variation in a manufacturing process, affecting the fit and function of the implant.

– B2B Importance: Tight tolerances are essential for ensuring that implants fit precisely within the patient’s anatomy. Inaccuracies can lead to complications, necessitating a careful selection of manufacturers who demonstrate precision engineering capabilities. -

Surface Treatment

– Definition: This refers to the processes applied to the implant surface to enhance osseointegration (the integration of the implant with bone).

– B2B Importance: Different surface treatments (e.g., sandblasting, acid etching) can significantly influence healing times and overall implant success. Buyers should inquire about specific surface treatments that align with their clinical needs. -

Porosity

– Definition: Porosity measures the amount of void space in the implant material, which can affect biological integration.

– B2B Importance: Implants with controlled porosity can promote better bone growth and stability. Understanding porosity is critical for buyers looking to achieve optimal clinical results. -

Load-Bearing Capacity

– Definition: This property describes the maximum weight an implant can support without failure.

– B2B Importance: Implants must withstand significant forces in the oral environment. Buyers should assess load-bearing specifications to ensure they meet the demands of various dental applications.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is essential for buyers to ensure quality control and supply chain integrity. Collaborating with reputable OEMs can enhance product reliability. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their inventory and budget. It can also indicate the supplier’s production capacity and market focus. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting price estimates for specific products or services.

– Importance: An RFQ is a critical tool for buyers to compare pricing and terms across multiple suppliers, aiding in negotiating favorable deals. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers in a transaction.

– Importance: Familiarity with Incoterms is vital for international transactions, as they dictate shipping responsibilities, costs, and risks. Understanding these terms can prevent disputes and enhance logistics planning. -

Lead Time

– Definition: The time between the initiation of an order and the delivery of the product.

– Importance: Recognizing lead times is critical for inventory management and ensuring that dental practices can meet patient needs without delays.

By grasping these essential technical properties and trade terminologies, B2B buyers can navigate the procurement of 3D dental implants more effectively, ensuring they make informed decisions that align with their operational and clinical requirements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 3d dental implants Sector

Market Overview & Key Trends

The global market for 3D dental implants is experiencing robust growth, driven by advancements in technology, increasing demand for dental restorations, and a rising emphasis on personalized healthcare solutions. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should be aware of key trends shaping this sector.

Digital Transformation: The integration of digital technologies, such as CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing), is revolutionizing the production of dental implants. This shift allows for more precise, customized solutions tailored to individual patient needs, reducing both time and costs for dental practices.

Material Innovation: Biocompatible materials are gaining traction, with manufacturers investing in research to develop stronger, lighter, and more durable options. This trend is particularly relevant for buyers looking to source high-quality implants that meet international standards.

Sourcing Trends: B2B buyers should consider local partnerships and suppliers to mitigate supply chain disruptions caused by global events. Sourcing from manufacturers that utilize advanced technologies not only ensures quality but also enhances the speed of delivery, a critical factor in dental practices.

Regulatory Compliance: As regulations around dental products become stricter, understanding local compliance requirements is essential. Buyers from Africa and South America, for instance, should familiarize themselves with both regional and international regulations governing dental implants to avoid costly penalties.

Sustainability & Ethical Sourcing in B2B

The environmental impact of dental implants cannot be overlooked. The production processes often involve significant resource consumption and waste generation. For B2B buyers, adopting sustainable practices in sourcing is crucial not only for compliance but also for enhancing brand reputation and meeting consumer expectations.

Importance of Ethical Supply Chains: Buyers should prioritize suppliers who adhere to ethical sourcing practices. This includes transparency in the supply chain, fair labor practices, and responsible sourcing of raw materials. Engaging with suppliers who are committed to sustainability can enhance a company’s corporate social responsibility (CSR) profile.

Green Certifications and Materials: Look for suppliers that offer products with recognized green certifications, such as ISO 14001 or those made from recycled or bio-based materials. These certifications can serve as a benchmark for quality and sustainability, helping buyers make informed decisions that align with their values and market demands.

By focusing on sustainability, B2B buyers can not only reduce their environmental footprint but also appeal to an increasingly eco-conscious customer base.

Brief Evolution/History

The evolution of dental implants has seen a significant transformation from traditional methods to modern 3D printing technologies. Initially, dental implants were crafted using conventional techniques, which often resulted in longer production times and less customization. The introduction of 3D printing in the early 2000s allowed for rapid prototyping and customization, enabling dental professionals to provide tailored solutions to patients.

As the technology matured, the focus shifted toward enhancing the biocompatibility and durability of materials used in implants. Today, 3D dental implants are not only more precise but also integrated with digital workflows, facilitating better patient outcomes and streamlined processes. This evolution underscores the importance for B2B buyers to stay abreast of technological advancements and their implications for sourcing strategies.

Related Video: ONESOURCE Global Trade: A Truly Global Solution

Frequently Asked Questions (FAQs) for B2B Buyers of 3d dental implants

-

What should I consider when vetting suppliers for 3D dental implants?

When vetting suppliers, prioritize their experience in the dental industry and their track record with international clients. Verify their certifications, such as ISO 13485, which demonstrates compliance with quality management systems. Request references from existing customers, particularly those in your region, to gauge reliability. Additionally, assess their ability to provide post-sale support and how they handle product recalls or issues, as this can significantly impact your business operations. -

Can 3D dental implants be customized to meet specific needs?

Yes, many suppliers offer customization options for 3D dental implants, allowing you to tailor products to your market’s requirements. It’s essential to communicate your specifications clearly, including dimensions, materials, and any unique features. Discuss the design process, including the use of CAD software and prototyping methods. Ensure that the supplier has experience in producing customized solutions and can provide samples for evaluation before committing to a larger order. -

What are the typical minimum order quantities (MOQs) and lead times for 3D dental implants?

MOQs for 3D dental implants can vary widely among suppliers, often depending on the complexity of the product and the supplier’s production capacity. Generally, MOQs range from 50 to 200 units. Lead times can also fluctuate based on customization and production schedules, typically ranging from 4 to 12 weeks. It’s advisable to discuss these factors upfront to align expectations and plan your inventory management accordingly. -

What payment terms should I expect when sourcing 3D dental implants?

Payment terms can differ based on the supplier’s policies and your negotiation leverage. Common terms include a deposit of 30-50% upon order confirmation, with the balance due before shipment. Some suppliers may offer letters of credit or financing options for larger orders. Always clarify payment methods accepted, as international transactions can incur additional fees or currency conversion costs. Establishing clear terms upfront helps avoid disputes later. -

How can I ensure quality assurance and certifications for 3D dental implants?

To ensure quality, request documentation of the supplier’s quality assurance processes and relevant certifications. Look for compliance with international standards like ISO 13485 and CE marking for the European market. Ask for test reports or certificates of conformity for the products you plan to purchase. Regular audits and inspections can also be a part of your quality assurance strategy, ensuring that the supplier maintains high standards throughout the production process. -

What logistics considerations should I keep in mind when importing 3D dental implants?

Logistics is critical when importing 3D dental implants. Consider the shipping methods available—air freight is faster but more expensive, while sea freight is cost-effective for larger orders. Understand the customs regulations in your country, including tariffs and import duties, to avoid unexpected costs. Collaborate with a reliable freight forwarder who has experience with medical products to navigate the complexities of international shipping and ensure timely delivery. -

How should I handle disputes with suppliers of 3D dental implants?

Disputes can arise from various issues, including product quality or delivery delays. It’s crucial to have a clear contract that outlines terms of engagement, including dispute resolution processes. Attempt to resolve issues amicably through direct communication first. If unresolved, consider mediation or arbitration as a next step, as these methods are often faster and less costly than litigation. Maintaining a professional relationship with suppliers can also facilitate smoother conflict resolution. -

What trends should I be aware of in the 3D dental implant market?

Stay informed about advancements in 3D printing technology, which can enhance the precision and customization of dental implants. Additionally, sustainability is becoming increasingly important; many suppliers are exploring eco-friendly materials and production methods. Monitor regulatory changes in key markets, as these can impact product compliance and market entry strategies. Engaging with industry associations and attending trade shows can provide valuable insights into emerging trends and networking opportunities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 3d dental implants

The landscape for 3D dental implants is rapidly evolving, offering significant opportunities for international B2B buyers to enhance their procurement strategies. As we conclude this exploration, it’s essential to recognize that strategic sourcing not only reduces costs but also elevates the quality of dental solutions offered to clients. By fostering partnerships with innovative manufacturers, buyers can ensure access to cutting-edge technology and materials that meet the increasing demands for precision and customization in dental care.

Key takeaways for B2B buyers include:

- Evaluate Suppliers Thoroughly: Prioritize manufacturers with a strong track record in quality assurance and compliance with international standards.

- Leverage Local Market Insights: Understanding regional preferences and regulatory requirements can streamline sourcing processes and enhance competitiveness.

- Embrace Technological Advancements: Investing in 3D printing technology can lead to significant cost savings and improved patient outcomes.

Looking ahead, the global demand for 3D dental implants is expected to rise, making now the time to act. Buyers from Africa, South America, the Middle East, and Europe should seize this moment to strengthen their sourcing strategies and position themselves as leaders in the dental market. Engage with reliable partners today to pave the way for sustainable growth and innovation in the dental sector.