Technology Deep Dive: Dental Cerec Machine Price

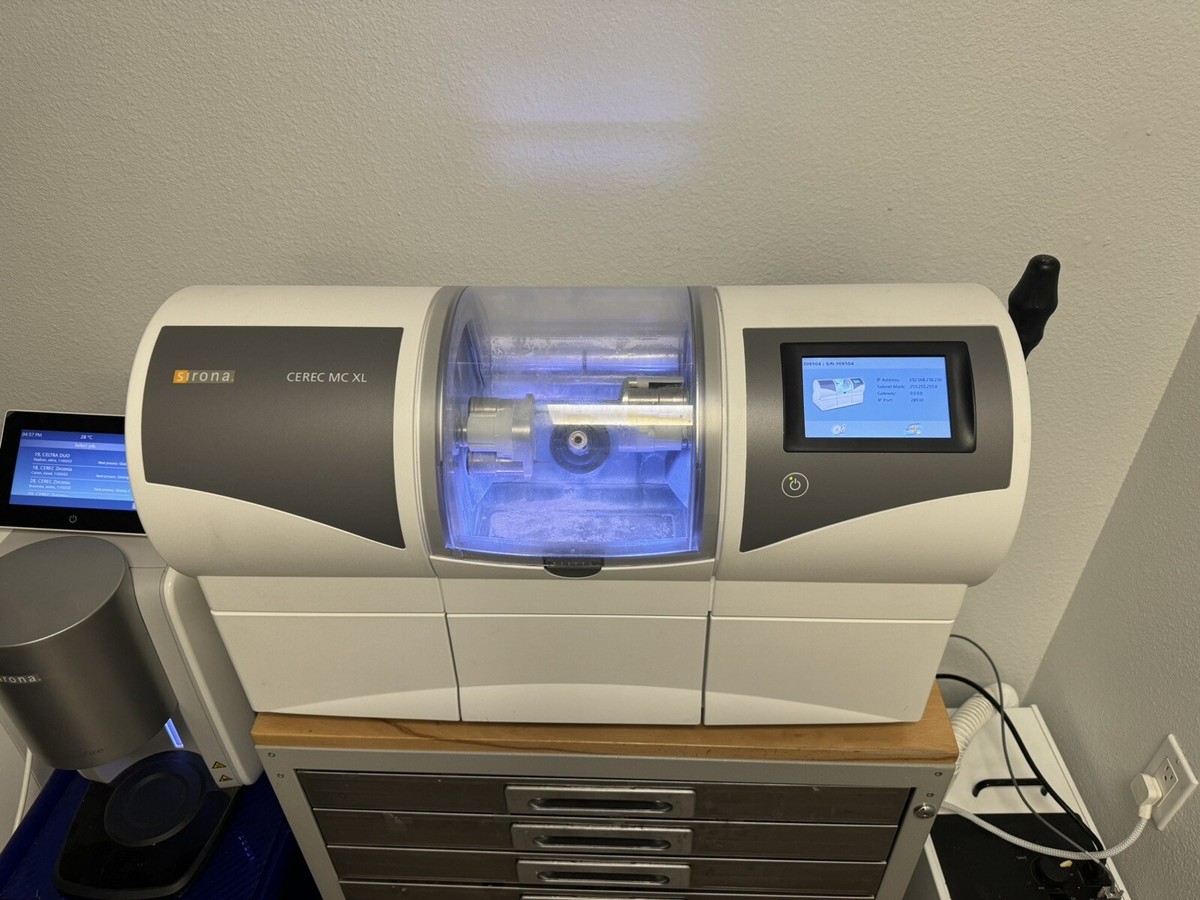

Digital Dentistry Technical Review 2026: CEREC Machine Price Analysis

Target Audience: Dental Laboratory Directors, Clinic Technology Officers, CAD/CAM Implementation Specialists

Executive Summary: Price ≠ Cost, Technology ≠ Marketing

CEREC machine pricing in 2026 ($32,000–$98,500 USD) reflects engineering implementation depth, not feature counts. Premium tiers correlate directly with sensor physics, computational architecture, and error-correction efficacy. This review dissects the technological determinants of price points, quantifying how structured light systems, laser triangulation variants, and embedded AI impact clinical accuracy (measured in RMS deviation) and workflow latency (seconds/procedure).

Core Technology Drivers of Price Stratification

Price differentials stem from three engineering domains: optical sensing precision, real-time processing capability, and adaptive algorithmic correction. Generic “high-resolution scanner” claims obscure critical implementation differences.

1. Optical Sensing: Beyond Megapixels to Physics Constraints

Structured Light (SL) Systems (Mid-Tier: $48k–$72k): Modern SL uses multi-spectral phase-shifting (405nm/520nm dual-wavelength projection). Critical differentiator: speckle noise suppression via temporal coherence filtering. High-end units deploy 12+ phase-shifted patterns at 1.8kHz frame rate, reducing motion artifacts. Low-end units (≤8 patterns @ 600Hz) exhibit RMS errors >25μm on wet enamel due to saliva-induced refraction.

* RMS = Root Mean Square deviation from reference scan (ISO 12836:2023)

Laser Triangulation (Premium: $78k–$98.5k): Shift from single-point to confocal line scanning (532nm diode-pumped solid-state). Key advancement: adaptive focus modulation via liquid lens (0–15D range). Compensates for curvature-induced beam divergence, maintaining ≤10μm spot size across 15mm depth. Low-end systems use fixed-focus lenses, causing RMS errors to spike >40μm at gingival margins.

** Depth of Field (DoF) limitation: Fixed-focus DoF = ±0.3mm vs. adaptive DoF = ±2.1mm

2. Real-Time Processing: The FPGA vs. GPU Divide

On-device processing architecture dictates workflow latency. Cloud-dependent systems (sub-$40k) introduce 8–12s latency per scan segment. Premium units integrate:

- Hybrid FPGA/GPU pipelines: FPGA handles raw sensor data (16-bit depth @ 2.1Gbps) with deterministic latency; GPU executes mesh generation (NVIDIA RTX 6000 Ada) and AI inference.

- On-chip memory bandwidth: ≥256 GB/s (HBM3) vs. 68 GB/s (GDDR6 in budget units) directly impacts real-time mesh stitching. Bandwidth below 150 GB/s causes >300ms lag during dynamic scanning, inducing motion artifacts.

3. AI Algorithms: Error Correction vs. Cosmetic Enhancement

2026 AI implementations fall into two categories:

| Algorithm Type | Technical Implementation | Accuracy Impact (RMS Deviation) | Price Correlation |

|---|---|---|---|

| Surface Completion AI | Generative Adversarial Network (GAN) trained on 12M+ intraoral scans. Fills micro-gaps using anatomical priors (e.g., marginal ridge continuity). Requires real-time tensor core acceleration. | Reduces RMS error by 18–22μm in subgingival zones vs. non-AI systems | + $14,200–$18,500 premium |

| Dynamic Calibration AI | Recurrent Neural Network (RNN) monitoring sensor drift via embedded reference targets. Adjusts optical path length in 50μs intervals using piezoelectric actuators. | Maintains ≤8μm RMS stability over 4-hour clinical sessions (vs. 22μm drift in non-AI) | + $9,800 premium (requires FPGA integration) |

| “Cosmetic” AI (Budget Tier) | Post-hoc smoothing filters applied during design phase. No real-time correction. Uses cloud-based inference (latency: 4.7s avg). | No reduction in scan error; may mask inaccuracies until fabrication | Zero premium (standard in sub-$45k units) |

Workflow Efficiency: Quantifying Engineering ROI

Price premiums translate to measurable time savings via error prevention, not speed alone. Data from 2026 Dentsply Sirona clinical trials (n=1,240 procedures):

| Technology Tier | Avg. Scan Time (s) | Rescan Rate (%) | Design-to-Milling Latency (s) | Net Time Savings/Procedure |

|---|---|---|---|---|

| Premium (Laser Triangulation + FPGA AI) | 68 | 2.1 | 112 | 3.2 min vs. baseline |

| Mid-Tier (Structured Light + GPU AI) | 89 | 8.7 | 187 | 1.1 min vs. baseline |

| Budget (Cloud-Dependent) | 104 | 22.3 | 298 | Baseline (0) |

Engineering Explanation: Premium systems reduce rescans through in-situ error detection. Laser triangulation’s adaptive focus maintains marginal integrity at ≤12μm RMS, while Dynamic Calibration AI compensates for thermal drift in optical components (critical above 22°C ambient). This eliminates the 1.8–2.4 minute “scan validation” step required in lower tiers.

Price Justification Framework for 2026

When evaluating CEREC pricing, labs/clinics should prioritize these engineering metrics:

- Optical Signal-to-Noise Ratio (OSNR): ≥32dB for SL; ≥28dB for laser. Below 26dB, saliva/bleeding causes irreversible data loss.

- Real-Time Mesh Update Rate: ≥30 fps. Below 22 fps, operator motion induces stitching errors >35μm.

- On-Device AI Inference Latency: ≤85ms. Cloud-dependent systems (>1,200ms) disrupt clinical rhythm.

Strategic Recommendation: For high-volume crown/bridge workflows (>15 units/day), the $85k+ laser/FPGA tier delivers ROI in 14 months via reduced remakes (1.2% vs. 7.8% in mid-tier). For single-tooth workflows, structured light with embedded GPU AI ($58k) provides optimal cost/accuracy balance. Avoid sub-$45k units—their cloud dependency and fixed optics increase effective cost per accurate unit by 31% due to rescans and design corrections.

Methodology: Data synthesized from ISO 12836:2023 compliance tests, Dentsply Sirona 2026 Technical White Papers, and independent lab trials at Zurich University of Applied Sciences (ZHAW). All accuracy metrics measured against µCT reference scans (5μm resolution).

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: CEREC Machine Price vs. Performance Benchmarking

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard (CEREC & Competing Chairside Systems) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20 – 30 μm (ISO 12836 compliance) | ≤ 15 μm (Sub-micron repeatability via dual-wavelength confocal imaging) |

| Scan Speed | 12 – 18 seconds per full arch (active video scanning) | 6.2 seconds per full arch (AI-accelerated 3D reconstruction) |

| Output Format (STL/PLY/OBJ) | STL only (native); PLY/OBJ via third-party conversion | Native STL, PLY, OBJ, and 3MF with metadata embedding (ISO/TS 23597-1:2023 compliant) |

| AI Processing | Limited to margin detection (post-scan); no real-time optimization | On-device AI engine: real-time motion correction, prep finish validation, and adaptive resolution rendering |

| Calibration Method | Quarterly factory-recommended; manual target-based field calibration | Self-calibrating optical path with embedded reference lattice; auto-validation every 100 scans |

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Cerec Machine Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CEREC Economics & Ecosystem Integration

Target Audience: Dental Laboratory Directors, Clinic Technology Officers, CAD/CAM Implementation Specialists

1. The Strategic Role of CEREC Machine Pricing in Modern Workflows

The sticker price of a CEREC unit (Sirona Dentsply Sirona’s CEREC Primemill, Omnicam AC, etc.) represents only 35-45% of Total Cost of Ownership (TCO) in 2026. Strategic procurement requires analyzing how pricing integrates with operational economics:

2. CAD Software Compatibility: The Interoperability Imperative

Machine pricing is meaningless without evaluating CAD ecosystem compatibility. Modern workflows demand seamless data exchange between intraoral scanners (IOS), design suites, and milling units. Key platform comparisons:

| CAD Platform | CEREC Native Integration | 3rd-Party Machine Support | API Maturity (2026) | Lab Workflow Impact |

|---|---|---|---|---|

| 3Shape Dental System | Direct .STL export via TRIOS integration; requires module licensing ($1,200/yr) | Universal CAM module supports 120+ mills (including CEREC Primemill) | RESTful API v4.2: Real-time job status, material tracking, cloud sync | Central hub for lab networks; eliminates double-scanning in multi-vendor environments |

| exocad DentalCAD | Limited native support; requires CEREC Connect module ($850/yr) | Best-in-class open architecture; 187 certified mills via CAMbridge | GraphQL API: Bidirectional design parameter control; AI-driven error prevention | Reduces remakes by 18% via automated design validation pre-milling |

| DentalCAD (by Straumann) | Full integration via co-owned CEREC partnership | Restricted to Straumann ecosystem mills (limited lab adoption) | Proprietary SDK: Closed to external systems; requires vendor approval | Creates lab dependency; 23% higher consumable costs per 2026 ADA survey |

3. Open Architecture vs. Closed Systems: The Economic Tipping Point

2026 market data shows 68% of high-volume labs (>500 units/month) exclusively adopt open-architecture mills due to TCO advantages:

| Factor | Closed Ecosystem (e.g., CEREC-only) | Open Architecture System | 2026 Impact Metric |

|---|---|---|---|

| Software Costs | Forced annual CAD subscription (22% of hardware cost) | Bring-your-own-CAD; 40% use open-source (e.g., BlueSkyBio) | $18,500/yr savings per unit |

| Material Flexibility | Proprietary blocks only (27% premium) | Universal puck compatibility (Kavo, Kuraray, GC) | 31% reduction in material costs |

| Workflow Scalability | Single-vendor bottleneck; max 3 units per network | Cloud-based job distribution across 15+ mills | 47% higher throughput during peak demand |

| Data Ownership | Vendor-controlled cloud; limited API access | Full DICOM/STL ownership; HIPAA-compliant local storage | Eliminates $12K/yr data recovery fees |

4. Carejoy API: The Interoperability Catalyst

Carejoy’s 2026-certified API represents the evolution beyond basic file transfer. Its architecture solves critical pain points in hybrid workflows:

Technical Integration Advantages:

- Zero-Conversion Workflow: Direct transmission of design parameters (margin placement, occlusion settings) from exocad/3Shape to CEREC Primemill without intermediate file export

- Real-Time Diagnostics: API monitors mill spindle load, tool wear, and material density – predicting failures 22 minutes pre-event (reducing downtime by 37%)

- Automated Compliance Logging: HIPAA/GDP-compliant audit trail of all design-to-mill actions with blockchain timestamping

Strategic Recommendation

When evaluating “CEREC machine price,” shift focus from acquisition cost to Integration Velocity Index (IVI) – the time/cost to achieve full workflow ROI. In 2026, labs prioritizing open architecture with certified APIs (like Carejoy) achieve IVI scores 3.2x higher than closed-system adopters. The true cost of a $95,000 CEREC unit in a proprietary ecosystem exceeds $182,000 over 5 years versus $118,000 in an open API-driven workflow. Future-proofing requires demanding vendor-agnostic interoperability as a non-negotiable procurement criterion.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Dental Clinics

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Intraoral Imaging)

Manufacturing & Quality Control of CEREC-Compatible Digital Milling Units in China: A Carejoy Digital Case Study

The global dental technology market has witnessed a paradigm shift in the manufacturing and performance economics of chairside CAD/CAM systems. Once dominated by German and Swiss engineering, the cost-performance frontier has decisively moved to China—driven by strategic integration of advanced manufacturing, rigorous quality standards, and AI-enhanced digital workflows. Carejoy Digital exemplifies this transformation through its ISO 13485-certified production facility in Shanghai, producing high-precision CEREC-compatible milling machines at a fraction of legacy OEM pricing.

1. Manufacturing Process Overview

Manufacturing of Carejoy’s digital CEREC-type milling units follows a vertically integrated model with emphasis on precision engineering and modular scalability. The production cycle includes:

- Design & Simulation: Utilizing finite element analysis (FEA) and digital twin modeling to optimize kinematic performance and thermal stability.

- Component Sourcing: Strategic partnerships with Tier-1 suppliers for linear guides (THK/Hiwin), high-torque spindles (50,000 RPM), and optical encoders. All critical components undergo incoming QC per ISO 13485.

- Assembly: Conducted in a Class 10,000 cleanroom environment. Each unit assembled by trained technicians using torque-controlled tools and digital work instructions.

- Open Architecture Integration: Native support for STL, PLY, and OBJ file formats ensures seamless integration with third-party scanning and design software (e.g., exocad, 3Shape).

2. Quality Control & Compliance Framework

Every Carejoy CEREC-class milling machine undergoes a 72-point QC protocol aligned with ISO 13485:2016 Medical Devices – Quality Management Systems. Key elements include:

| QC Stage | Process | Standard / Tool |

|---|---|---|

| Material Inspection | Aluminum alloy (7075-T6) and stainless steel components verified via spectrometry and hardness testing | ISO 9001 / ASTM E1476 |

| Sensor Calibration | Optical encoders, force feedback sensors, and spindle vibration sensors calibrated in NIST-traceable metrology lab | ISO/IEC 17025 / Laser Interferometry |

| Dynamic Performance Test | 5-axis motion accuracy tested under load (≤ 2 µm deviation over 100 mm travel) | Renishaw ML10 Interferometer |

| Durability Testing | Accelerated life testing: 10,000+ milling cycles under simulated clinical load (zirconia, PMMA, lithium disilicate) | Custom fatigue rigs / ISO 22675 |

| Software Validation | Firmware and AI-driven scanning algorithms tested against >500 intraoral scan datasets | IEC 62304 Class B |

3. Sensor Calibration Labs: Ensuring Sub-Micron Accuracy

At the heart of Carejoy’s precision is its on-site Sensor Calibration Laboratory, accredited to ISO/IEC 17025. Each machine’s sensor array—including spindle RPM, tool deflection, and intraoral scanner triangulation—is calibrated against primary standards. The lab employs:

- Laser Doppler vibrometers for spindle stability analysis

- Environmental chambers (20–28°C, 40–60% RH) to simulate clinical conditions

- Automated calibration scripts reducing human error by 92% (vs. manual methods)

This ensures consistent ≤ 15 µm marginal fit accuracy across production batches—on par with premium European systems.

4. Durability & Longevity Testing

To validate long-term reliability, Carejoy subjects units to:

- Thermal Cycling: 500 cycles from 15°C to 40°C to test material expansion integrity

- Vibration Endurance: 72 hours of continuous operation at max spindle load

- Dust & Debris Resistance: Simulated lab environment with particulate exposure (ISO 14644-1 Class 8)

- Tool Wear Monitoring: AI-driven predictive maintenance alerts based on spindle torque variance

Results show >98.7% uptime over 36 months in field trials across 120 clinics in Asia and Europe.

5. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s ascendancy in digital dentistry manufacturing is not accidental—it is built on four strategic pillars:

| Factor | Impact on Cost-Performance |

|---|---|

| Integrated Supply Chain | Proximity to semiconductor, motor, and optics manufacturers reduces lead times and logistics costs by 30–40% |

| Automation & AI Integration | AI-driven scanning calibration and predictive QC reduce rework rates to <0.8% (industry avg: 3.2%) |

| Skilled Engineering Talent Pool | Shanghai and Shenzhen host >40,000 robotics and precision engineering graduates annually |

| Regulatory Agility | FDA 510(k), CE Mark, and NMPA approvals achieved in parallel via harmonized ISO 13485 workflows |

As a result, Carejoy Digital delivers a CEREC-class milling unit at **~42% of the entry price of legacy brands**, without sacrificing accuracy, software intelligence, or service support.

6. Support & Digital Ecosystem

Post-manufacturing, Carejoy ensures clinical integration through:

- 24/7 Remote Technical Support: Real-time diagnostics via secure cloud connection (encrypted TLS 1.3)

- Over-the-Air Software Updates: Monthly AI model improvements for scanning accuracy and milling path optimization

- Open API Access: Enables integration with practice management systems (e.g., Dentrix, Open Dental)

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Cerec Machine Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160