Introduction: Navigating the Global Market for transosteal dental implants

Transosteal dental implants represent a significant advancement in dental restoration, providing a reliable solution for patients with insufficient bone density or complex dental issues. As global demand for dental solutions increases, understanding the nuances of transosteal implants becomes essential for international B2B buyers. This guide serves as a comprehensive resource, offering insights into various types of transosteal implants, the materials used in their construction, manufacturing and quality control processes, and key suppliers in the market.

In the rapidly evolving dental landscape, buyers must navigate challenges such as fluctuating costs, diverse regional regulations, and varying quality standards. This guide empowers decision-makers from Africa, South America, the Middle East, and Europe—countries like Italy and Kenya—to make informed sourcing decisions. By delving into market trends, competitive analysis, and frequently asked questions, this resource equips buyers with the knowledge to assess suppliers critically and ensure optimal investment in dental solutions.

Furthermore, understanding the market dynamics surrounding transosteal dental implants is crucial for leveraging opportunities in both established and emerging markets. With a focus on actionable insights, this guide not only clarifies the complexities of transosteal implants but also supports strategic partnerships that can enhance dental practices globally. The journey through this guide will facilitate a deeper understanding of transosteal dental implants, ultimately leading to more informed purchasing decisions and improved patient outcomes.

Understanding transosteal dental implants Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Transosteal Implants | Pass through the mandible or maxilla; typically used for lower jaw restoration | Dental surgeries, prosthodontics | Pros: High stability; suitable for patients with severe bone loss. Cons: Invasive; longer healing time. |

| Plate-Screw Implants | Combines plates and screws for enhanced stability; often used in cases with significant bone resorption | Complex dental restorations, reconstructive surgery | Pros: Excellent retention; versatile for various cases. Cons: Higher costs; more complex installation. |

| Zygomatic Implants | Anchored in the zygomatic bone; ideal for patients with insufficient maxillary bone | Advanced dental restorations | Pros: Avoids bone grafting; immediate loading possible. Cons: Requires specialized skills; higher risk of complications. |

| Subperiosteal Implants | Placed under the periosteum; suitable for patients with minimal bone height | Custom restorations, dental tourism | Pros: Less invasive; good for patients with limited bone. Cons: Limited availability; potential for lower stability. |

| Immediate Load Implants | Allows for immediate restoration post-surgery; beneficial for patient satisfaction | Fast-track dental solutions, aesthetics | Pros: Immediate results; improved patient experience. Cons: Requires precise placement; risk of failure if not done correctly. |

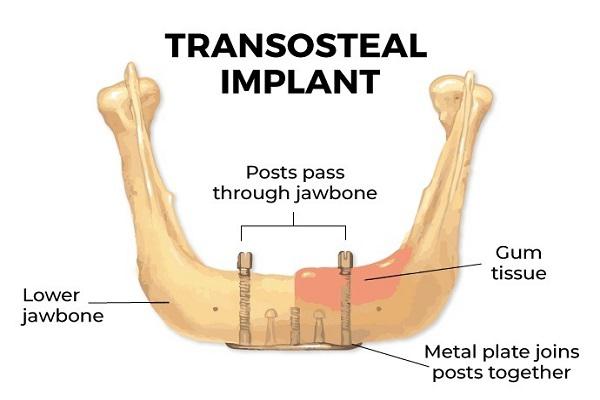

Transosteal Implants

Transosteal implants are characterized by their design that passes through the mandible or maxilla, making them particularly effective for lower jaw restorations. These implants are often used in patients with significant bone loss, providing a robust solution for anchoring prosthetics. B2B buyers should consider the invasiveness of the procedure and the longer healing time associated with these implants when assessing their suitability for specific patient demographics.

Plate-Screw Implants

Plate-screw implants integrate plates and screws for enhanced stability and are often utilized in complex dental restorations and reconstructive surgeries. Their design allows for an adaptable solution in cases of significant bone resorption. Buyers should evaluate the costs and complexity of installation, as these factors can impact the overall feasibility of using plate-screw implants in various settings.

Zygomatic Implants

Zygomatic implants are anchored in the zygomatic bone, making them an ideal choice for patients with insufficient maxillary bone. This type of implant can often avoid the need for bone grafting and allows for immediate loading, which can significantly enhance patient satisfaction. B2B buyers must consider the specialized skills required for placement and the associated risks, ensuring that their dental teams are adequately trained.

Subperiosteal Implants

Subperiosteal implants are placed under the periosteum and are particularly suited for patients with minimal bone height. This type of implant offers a less invasive alternative for those who may not be candidates for traditional implants. B2B buyers should be aware of the limited availability of subperiosteal implants and the potential for lower stability compared to other types.

Immediate Load Implants

Immediate load implants allow for the restoration of function and aesthetics soon after surgery, catering to the growing demand for fast-track dental solutions. This type of implant enhances the patient experience by providing immediate results, which is particularly appealing in competitive markets. Buyers should weigh the precision required for placement against the benefits of improved patient satisfaction, as improper placement can lead to complications and implant failure.

Related Video: 3 Types of Dental Implants and Surface treatments explained!

Key Industrial Applications of transosteal dental implants

| Industry/Sector | Specific Application of transosteal dental implants | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Restorative dentistry for patients with severe bone loss | Restores functionality and aesthetics, improving patient satisfaction and clinic reputation | Quality assurance, regulatory compliance, and after-sales support |

| Dental Laboratories | Custom implant fabrication and prosthetic solutions | Enables tailored solutions for diverse patient needs, enhancing service offerings | Material sourcing, technological capabilities, and design flexibility |

| Dental Tourism Providers | Comprehensive dental care packages for international patients | Attracts global clientele seeking high-quality, affordable dental solutions | Partnerships with reputable clinics, logistics, and patient support |

| Orthodontic Practices | Integration with orthodontic treatments for enhanced stability | Improves overall treatment outcomes, leading to higher patient retention | Compatibility with existing orthodontic systems and treatment plans |

| Research Institutions | Clinical studies on implant performance and innovation | Contributes to advancements in dental technology, attracting funding and partnerships | Collaboration opportunities, ethical compliance, and access to patient data |

Detailed Application Insights

Dental Clinics:

Transosteal dental implants are particularly valuable in restorative dentistry, especially for patients suffering from significant bone loss. These implants provide a robust foundation for prosthetic teeth, enabling dentists to restore both functionality and aesthetics. For international B2B buyers, sourcing high-quality implants that comply with local regulations and standards is crucial. Additionally, clinics should prioritize suppliers that offer reliable after-sales support to address any post-implantation issues.

Dental Laboratories:

In dental laboratories, transosteal dental implants are utilized for the fabrication of custom solutions tailored to individual patient needs. This application allows labs to produce prosthetic devices that fit precisely and function effectively, thereby enhancing their service offerings. Buyers in this sector should focus on sourcing materials that meet stringent quality standards and ensure the technological capabilities of their suppliers can support innovative design processes.

Dental Tourism Providers:

Dental tourism providers leverage transosteal dental implants as part of comprehensive care packages aimed at international patients seeking high-quality and cost-effective dental solutions. By incorporating these implants into their offerings, they can attract clients from regions with high dental costs. Key considerations for sourcing include establishing partnerships with reputable clinics that use advanced implant technologies and ensuring efficient logistics to facilitate patient travel and care.

Orthodontic Practices:

Transosteal dental implants can be integrated into orthodontic treatments to provide enhanced stability, particularly in complex cases requiring additional support. This integration can significantly improve treatment outcomes, leading to increased patient satisfaction and retention. B2B buyers in this field should ensure that the implants are compatible with existing orthodontic systems and consider the long-term implications of their use in conjunction with other dental treatments.

Research Institutions:

For research institutions, transosteal dental implants represent a vital area of study, particularly in clinical trials focused on implant performance and innovations. Engaging in research related to these implants can attract funding and foster partnerships with dental manufacturers. Buyers in this sector should prioritize ethical compliance and seek collaborative opportunities that provide access to extensive patient data for meaningful research outcomes.

Strategic Material Selection Guide for transosteal dental implants

When selecting materials for transosteal dental implants, international B2B buyers must consider various factors including mechanical properties, biocompatibility, and manufacturing complexities. Below, we analyze four common materials used in transosteal dental implants, focusing on their properties, advantages, disadvantages, and considerations for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

Titanium Alloys

Key Properties: Titanium alloys, particularly Ti-6Al-4V, exhibit excellent strength-to-weight ratios, high corrosion resistance, and biocompatibility. They can withstand significant mechanical loads and are resistant to degradation in bodily fluids.

Pros & Cons: The durability of titanium alloys makes them a preferred choice for dental implants. However, they can be more expensive compared to other materials, and their manufacturing processes may require advanced techniques like CNC machining, which can increase lead times.

Impact on Application: Titanium’s compatibility with bone tissue promotes osseointegration, making it suitable for long-term applications in dental restoration.

Considerations for Buyers: Buyers must ensure compliance with international standards such as ASTM F136 for titanium alloys. Understanding local regulations regarding material sourcing and biocompatibility testing is crucial, especially in regions with stringent health regulations.

Zirconia

Key Properties: Zirconia is known for its aesthetic appeal, high strength, and excellent wear resistance. It is also highly biocompatible and offers a lower thermal conductivity than metals.

Pros & Cons: The aesthetic quality of zirconia is a significant advantage, particularly for visible dental implants. However, it can be more brittle than titanium, which may limit its use in load-bearing applications. The manufacturing process can also be complex, requiring specific sintering techniques.

Impact on Application: Zirconia implants are often used in anterior dental restorations where aesthetics are paramount. However, their brittleness may pose risks in posterior applications where chewing forces are higher.

Considerations for Buyers: Buyers should be aware of the need for specific certifications, such as ISO 13485 for medical devices. Additionally, understanding the local market demand for aesthetic solutions can guide purchasing decisions.

Stainless Steel

Key Properties: Stainless steel, particularly 316L, offers good corrosion resistance and mechanical strength. It is also relatively cost-effective and easy to manufacture.

Pros & Cons: While stainless steel is durable and less expensive than titanium, it lacks the same level of biocompatibility and can corrode over time when exposed to bodily fluids. This limits its use in long-term applications.

Impact on Application: Stainless steel may be suitable for temporary implants or in cases where cost is a primary concern, but it is not ideal for permanent solutions.

Considerations for Buyers: Buyers should consider local regulations regarding the use of stainless steel in medical applications, as some regions may have restrictions due to biocompatibility concerns.

Polyether Ether Ketone (PEEK)

Key Properties: PEEK is a high-performance polymer known for its excellent mechanical properties, chemical resistance, and biocompatibility. It can withstand high temperatures and is lightweight.

Pros & Cons: PEEK’s flexibility and strength make it suitable for various dental applications. However, it is generally less durable than metals and can be more expensive due to its specialized manufacturing processes.

Impact on Application: PEEK is often used in cases where flexibility is needed, such as in certain prosthetic applications. Its compatibility with imaging techniques is also an advantage.

Considerations for Buyers: Buyers should ensure that PEEK implants meet relevant standards such as ASTM F2026. Understanding the local market’s acceptance of polymer-based implants is essential for successful procurement.

| Material | Typical Use Case for transosteal dental implants | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium Alloys | Long-term dental implants | Excellent strength and biocompatibility | Higher cost and complex manufacturing | High |

| Zirconia | Aesthetic anterior restorations | Superior aesthetics and wear resistance | Brittle under high loads | Medium |

| Stainless Steel | Temporary implants | Cost-effective and durable | Poor biocompatibility and corrosion risk | Low |

| PEEK | Flexible prosthetic applications | Lightweight and chemically resistant | Less durable than metals | Medium |

This guide provides a comprehensive overview for international B2B buyers to make informed decisions regarding the selection of materials for transosteal dental implants, ensuring compliance and suitability for their specific market needs.

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for transosteal dental implants

The manufacturing process for transosteal dental implants involves several critical stages that ensure the final product meets the necessary standards for functionality, safety, and aesthetic appeal. B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be well-informed about these processes and quality assurance measures to make educated purchasing decisions.

Manufacturing Process

1. Material Preparation

The choice of materials is paramount in the production of transosteal dental implants. Typically, biocompatible materials such as titanium or titanium alloys are used due to their excellent mechanical properties and resistance to corrosion. The manufacturing process begins with the procurement of raw materials, which must undergo rigorous inspection to ensure they meet specified standards.

- Material Sourcing: Ensure suppliers provide documentation regarding the origin and quality of materials.

- Initial Testing: Conduct chemical composition analysis to verify the material’s suitability for dental applications.

2. Forming

The forming stage involves shaping the raw materials into the desired implant configuration. This can be achieved through various techniques:

- CNC Machining: Computer Numerical Control (CNC) machining is widely used for precision shaping of the implant components. This method allows for tight tolerances and intricate designs.

- Additive Manufacturing: Emerging technologies such as 3D printing are being adopted to create complex geometries that traditional methods cannot achieve. This technique enhances customization for specific patient needs.

3. Assembly

Once individual components are formed, they must be assembled. For transosteal implants, this usually involves the integration of various parts, such as the implant body and abutment.

- Welding and Bonding: Techniques like laser welding may be employed to ensure strong and durable joints between components.

- Alignment and Fitting: Precision is critical during assembly to ensure that components fit together correctly, which is essential for the implant’s functionality.

4. Finishing

The finishing stage focuses on enhancing the surface properties of the implants. This is crucial for promoting osseointegration—the process through which the implant bonds with the jawbone.

- Surface Treatment: Various treatments, such as sandblasting or acid etching, are applied to increase surface roughness, which can improve biological integration.

- Polishing and Coating: Final polishing may be done to enhance aesthetic qualities, while coatings (like hydroxyapatite) can be applied to facilitate bone growth.

Quality Assurance

Quality assurance is integral to the manufacturing process of transosteal dental implants. B2B buyers should be familiar with international standards and industry-specific regulations to ensure they procure high-quality products.

Relevant International Standards

- ISO 9001: This standard outlines the criteria for a quality management system and is applicable to any organization. Compliance indicates that the manufacturer has a systematic approach to managing quality.

- CE Marking: In Europe, CE marking signifies that a product meets health, safety, and environmental protection standards. It is crucial for transosteal implants sold in the European market.

- API Standards: The American Petroleum Institute (API) standards may apply to certain materials and manufacturing processes, especially when implants are made from specific alloys or composites.

Quality Control Checkpoints

Quality control (QC) checkpoints are essential throughout the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify issues early, ensuring corrective actions can be implemented immediately.

- Final Quality Control (FQC): This final inspection ensures that the finished products meet all design and functional specifications before shipping.

Common Testing Methods

Several testing methods are utilized to assess the quality of transosteal dental implants:

- Mechanical Testing: This includes tensile, compression, and fatigue testing to evaluate the strength and durability of the implants.

- Biocompatibility Testing: Ensures that the materials used do not provoke an adverse reaction in the human body.

- Sterility Testing: For implants intended for surgical use, ensuring sterility is critical to prevent infections.

Verifying Supplier Quality Control

B2B buyers should take proactive steps to verify the quality control practices of potential suppliers:

-

Supplier Audits: Conduct regular audits to assess compliance with international standards and internal quality procedures. This may include site visits and comprehensive reviews of quality management systems.

-

Quality Reports: Request detailed quality reports that outline QC processes, testing results, and corrective actions taken for any identified issues.

-

Third-Party Inspections: Engage independent third-party organizations to conduct inspections and audits. This provides an unbiased assessment of the supplier’s quality management practices.

QC/CERT Nuances for International Buyers

International buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality certification:

-

Regulatory Variations: Different regions may have varying regulations regarding dental implants. Buyers must ensure that the products meet the specific regulatory requirements of their target markets.

-

Cultural Considerations: Understanding local market expectations regarding quality and certification can aid in selecting the right suppliers. For instance, European buyers may prioritize CE certification, while Middle Eastern buyers might focus on local health authority approvals.

-

Logistics and Supply Chain Management: Be aware of how quality assurance measures can impact delivery times and supply chain efficiency. Engage with suppliers that have robust logistics and quality systems to avoid delays and ensure product integrity.

In conclusion, understanding the manufacturing processes and quality assurance measures for transosteal dental implants is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, along with adhering to quality standards, buyers can ensure they source reliable and effective dental implant products.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for transosteal dental implants Sourcing

In the competitive landscape of transosteal dental implants, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis provides insights into the various components influencing costs, factors affecting pricing, and actionable tips for effective sourcing.

Cost Structure of Transosteal Dental Implants

The cost of transosteal dental implants can be broken down into several key components:

-

Materials: The choice of materials significantly impacts costs. Common materials include titanium and zirconia, which offer durability and biocompatibility. The quality of these materials can affect both the price and the performance of the implants.

-

Labor: Skilled labor is required for the manufacturing and assembly of dental implants. Labor costs can vary widely based on geographical location and local wage standards. In regions like Europe, labor costs tend to be higher compared to Africa or South America.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment depreciation, and facility maintenance. Efficient manufacturing processes can help reduce these costs, making it essential for buyers to assess suppliers’ operational efficiencies.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. Buyers should consider whether they require standard or bespoke implants, as this will influence tooling investments.

-

Quality Control (QC): Rigorous quality assurance processes are necessary to ensure the safety and efficacy of implants. While this may add to costs, it is crucial for maintaining product standards and regulatory compliance.

-

Logistics: Transportation costs, including shipping and handling, can vary based on the distance and mode of transport. International buyers must account for potential tariffs and import duties as well.

-

Margin: Supplier margins will vary based on market positioning and the perceived value of their products. Buyers should be aware that higher margins often correlate with enhanced service levels or proprietary technologies.

Price Influencers

Several factors can influence the pricing of transosteal dental implants:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate for bulk pricing to maximize savings.

-

Specifications/Customization: Custom implants tailored to specific needs may incur higher costs. Clear communication of requirements can help minimize unnecessary expenses.

-

Materials and Quality Certifications: Implants that meet stringent quality standards (e.g., ISO certifications) may carry a premium price. Buyers should weigh the benefits of certified products against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a track record of quality may charge more but offer greater assurance of performance.

-

Incoterms: The choice of Incoterms impacts shipping costs and responsibilities. Understanding these terms is vital for managing total costs effectively.

Buyer Tips for Cost-Efficiency

-

Negotiation: Engage in open discussions with suppliers to explore discounts for larger orders or long-term contracts. Building a strong relationship can lead to better pricing and terms.

-

Total Cost of Ownership (TCO): Assess not just the upfront costs, but also long-term expenses such as maintenance, warranty, and support. A lower initial price may not always translate to overall savings.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and how they may impact costs. Establishing contracts in stable currencies can mitigate risk.

-

Research and Benchmarking: Conduct thorough market research to compare pricing across different suppliers and regions. This can help identify competitive pricing and ensure you are getting value for your investment.

Disclaimer

The prices discussed in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult multiple suppliers and conduct a comprehensive analysis tailored to your sourcing needs.

Essential Technical Properties and Trade Terminology for transosteal dental implants

Transosteal dental implants are a specialized type of dental implant that offer unique advantages and considerations for B2B buyers in the dental industry. Understanding the essential technical properties and trade terminology is crucial for making informed purchasing decisions.

Key Technical Properties

-

Material Grade

– Definition: Transosteal implants are commonly made from titanium or titanium alloys due to their biocompatibility and strength.

– B2B Importance: Selecting high-grade materials ensures durability and reduces the risk of implant failure, which can lead to costly replacements and legal liabilities. -

Tolerance Levels

– Definition: Tolerance refers to the permissible limit of variation in a physical dimension, such as the diameter of the implant.

– B2B Importance: Precise tolerances are critical for ensuring a proper fit within the bone structure. Poor tolerances can lead to complications in the surgical process and affect the longevity of the implant. -

Surface Treatment

– Definition: The surface of transosteal implants may undergo treatments such as sandblasting or acid etching to enhance osseointegration.

– B2B Importance: Effective surface treatments improve the implant’s ability to bond with bone, reducing healing times and increasing success rates, which is a key selling point in competitive markets. -

Load-Bearing Capacity

– Definition: This property indicates the maximum load the implant can withstand during normal chewing and biting.

– B2B Importance: Understanding load-bearing capacity helps dental professionals assess whether the implant is suitable for specific patient needs, especially in cases requiring full-arch restorations.

Illustrative Image (Source: Google Search)

- Design Features

– Definition: Various designs exist, such as cylindrical or tapered implants, which affect placement and stability.

– B2B Importance: Different designs cater to various anatomical needs, influencing the decision-making process for suppliers and dental practitioners focused on patient-specific solutions.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Context: Understanding OEM relationships helps buyers identify reliable sources for implants and components, ensuring quality and compliance with industry standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Context: Knowing the MOQ is essential for budget planning and inventory management, particularly for smaller dental practices or suppliers in emerging markets. -

RFQ (Request for Quotation)

– Definition: A document issued to suppliers to invite them to submit price proposals for specific products or services.

– Context: An RFQ is a critical step in the procurement process, allowing buyers to compare prices and terms from multiple suppliers effectively. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers.

– Context: Familiarity with Incoterms is vital for international transactions, particularly for buyers in Africa, South America, and the Middle East, as they dictate shipping costs, risks, and responsibilities. -

Lead Time

– Definition: The amount of time taken from the initiation of a process until its completion.

– Context: Understanding lead times is crucial for planning inventory and ensuring timely delivery of implants, which can significantly impact patient care and satisfaction.

By grasping these technical properties and trade terms, B2B buyers in the dental implant sector can make more informed purchasing decisions, enhancing operational efficiency and ensuring better outcomes for their clients.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the transosteal dental implants Sector

Market Overview & Key Trends

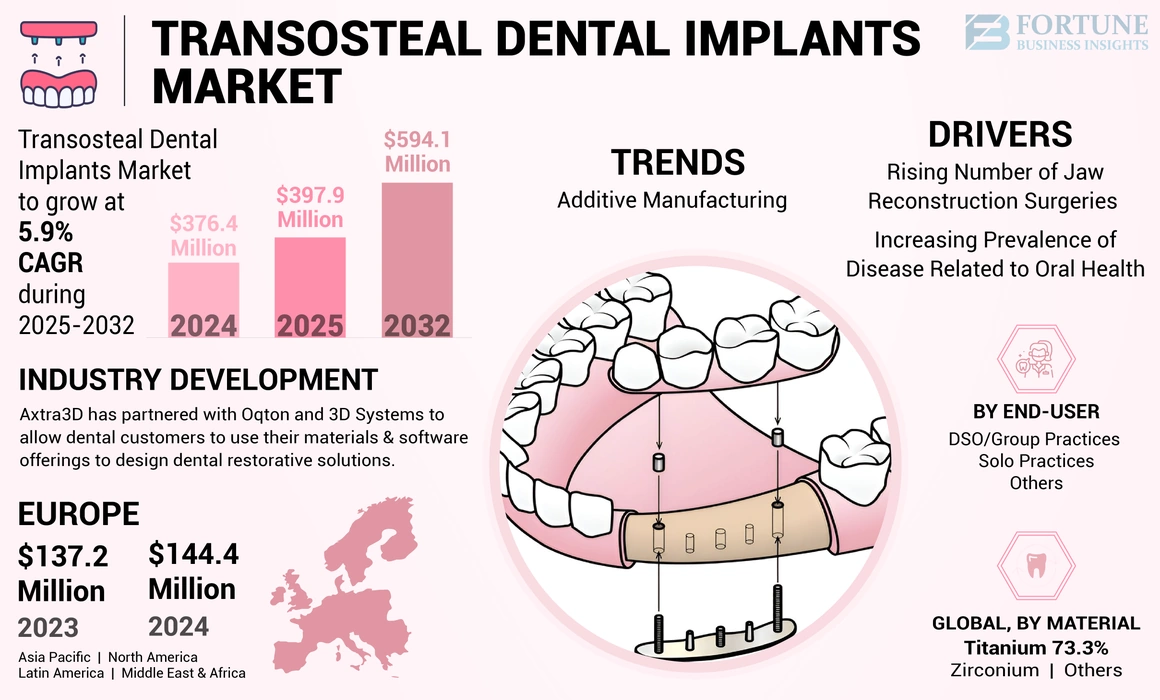

The transosteal dental implants market is experiencing significant transformation driven by technological advancements and evolving consumer demands. Global drivers include an aging population, increasing dental awareness, and a rise in dental tourism, particularly in regions like Africa and South America. International buyers are noticing the surge in demand for high-quality dental implants that offer enhanced durability and aesthetic appeal.

Current and emerging B2B tech trends such as additive manufacturing (3D printing) are revolutionizing the production of dental implants, enabling customized solutions tailored to individual patient needs. This technology not only reduces lead times but also minimizes waste, appealing to environmentally conscious buyers. Additionally, the integration of digital dentistry, including CAD/CAM systems, is streamlining the design and manufacturing processes, making them more efficient and cost-effective.

Market dynamics indicate that buyers from regions like the Middle East and Europe are increasingly seeking suppliers that can provide both quality and compliance with international standards. Competitive pricing remains essential, but B2B buyers are now prioritizing suppliers that demonstrate innovation and reliability. As such, understanding local market conditions and regulatory requirements is crucial for international buyers looking to source transosteal dental implants.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal concern in the transosteal dental implants sector. The environmental impact of manufacturing processes and materials used in dental implants cannot be overlooked. B2B buyers are encouraged to consider suppliers that prioritize sustainable practices, including the use of biocompatible and eco-friendly materials.

Ethical supply chains are essential for fostering trust and transparency. Buyers should evaluate suppliers based on their sourcing practices, labor conditions, and adherence to ethical standards. Certifications such as ISO 14001 (Environmental Management) and ISO 13485 (Medical Devices) can serve as benchmarks for assessing the sustainability of suppliers.

Moreover, the demand for ‘green’ certifications is rising, as customers increasingly prefer products that are not only effective but also environmentally responsible. This trend is particularly relevant in Europe, where stringent regulations on medical devices encourage companies to adopt sustainable practices. For international buyers, aligning with suppliers that demonstrate commitment to sustainability can enhance brand reputation and meet the expectations of a growing environmentally conscious consumer base.

Brief Evolution/History

Transosteal dental implants have a rich history that traces back to the mid-20th century when advancements in dental surgery and implant technology began to emerge. Initially used primarily for anchoring dental prosthetics, the design and application of these implants have evolved significantly.

In recent decades, the shift towards osseointegration—where the implant fuses with the bone—has revolutionized their effectiveness and longevity. As research has progressed, innovations in materials and manufacturing processes, such as titanium and ceramic implants, have improved both the aesthetic and functional aspects of transosteal implants. Today, the sector continues to evolve with a focus on customization and patient-specific solutions, reflecting the broader trends in healthcare towards personalized medicine and improved patient outcomes.

This historical context is vital for B2B buyers as it highlights the ongoing advancements and the importance of sourcing from suppliers who are at the forefront of innovation in the dental implant industry. Understanding this evolution can aid in making informed decisions when selecting products and suppliers.

Related Video: Global Trends Chapter 2 | Part 1 | Video Posted!

Frequently Asked Questions (FAQs) for B2B Buyers of transosteal dental implants

-

What factors should I consider when vetting suppliers of transosteal dental implants?

When vetting suppliers, prioritize their experience in the dental implant market, checking for certifications such as ISO 13485 and CE marking. Evaluate their manufacturing capabilities and quality control processes. Request references from previous clients and review their track record for reliability and product quality. Additionally, assess their ability to provide customized solutions and their responsiveness to inquiries, as these factors can significantly impact your partnership. -

Can transosteal dental implants be customized for specific needs?

Yes, many suppliers offer customization options for transosteal dental implants. This can include variations in size, shape, and materials based on the specific requirements of your market or clientele. Discuss your needs early in the procurement process to ensure the supplier can accommodate your requests. Be aware that customization may affect the lead times and pricing, so factor these into your planning. -

What are the typical minimum order quantities (MOQ) and lead times for transosteal dental implants?

MOQs for transosteal dental implants can vary significantly among suppliers, typically ranging from 50 to 200 units per order. Lead times can also differ based on the supplier’s location, production capacity, and whether customization is required, usually ranging from 4 to 12 weeks. Always confirm these details with your chosen supplier before placing an order to align your inventory needs with their production schedules. -

What payment terms should I expect when sourcing transosteal dental implants internationally?

Payment terms can vary by supplier and region, but common practices include upfront payments (30-50% deposit) followed by the balance upon shipment. Some suppliers may offer credit terms for established relationships. Be sure to clarify payment methods accepted (e.g., bank transfer, credit card) and any additional fees for international transactions. Negotiating favorable terms can enhance cash flow management for your business. -

What quality assurance measures should I look for in transosteal dental implants?

Ensure that the supplier adheres to international quality standards, such as ISO 13485 for medical devices. Request documentation of their quality assurance processes, including testing protocols for biocompatibility and mechanical strength. Additionally, inquire about their product traceability and any certifications that validate the safety and efficacy of their implants. Regular audits and quality control checks are also essential indicators of a reliable supplier. -

How do logistics and shipping impact the procurement of transosteal dental implants?

Logistics play a critical role in the timely delivery of dental implants. Consider the supplier’s shipping capabilities, including their experience with international freight and customs clearance. Discuss options for air versus sea freight based on urgency and cost. Ensure that the supplier provides adequate packaging to prevent damage during transit and inquire about insurance options for high-value shipments. -

What steps can I take to resolve disputes with suppliers of transosteal dental implants?

To minimize disputes, establish clear contractual agreements outlining terms, delivery schedules, and quality expectations. In the event of a disagreement, maintain open communication with the supplier to seek resolution amicably. If necessary, refer to the contract’s dispute resolution clause, which may include mediation or arbitration. Building a strong relationship with suppliers can also facilitate better problem-solving and negotiation. -

How can I stay informed about regulatory changes affecting transosteal dental implants?

Regularly consult industry publications, trade associations, and regulatory bodies in your region to stay updated on changes affecting dental implants. Engage with suppliers who are proactive in providing updates on compliance with international standards and regulations. Consider attending dental conferences and trade shows, which can provide valuable insights into emerging trends and regulatory developments in the dental implant sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for transosteal dental implants

In summary, the strategic sourcing of transosteal dental implants offers significant advantages for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe. By prioritizing quality, cost-effectiveness, and supplier reliability, businesses can ensure that they meet the increasing demand for advanced dental solutions. Establishing partnerships with manufacturers who utilize innovative technologies, such as additive manufacturing, can lead to enhanced product offerings and improved patient outcomes.

Key Takeaways:

– Quality Assurance: Focus on suppliers that adhere to international standards and certifications to ensure the safety and efficacy of implants.

– Cost Management: Leverage competitive pricing without compromising quality by exploring suppliers across different regions, including emerging markets.

– Supplier Relationships: Foster long-term partnerships with manufacturers that can provide consistent support and innovation.

As the market for dental implants continues to evolve, it is crucial for B2B buyers to remain proactive. Embrace technological advancements and seek out strategic alliances that enhance your product portfolio. Now is the time to invest in transosteal dental implants and position your business for success in a growing sector.