Introduction: Navigating the Global Market for tooth extraction and dental implants

In the evolving landscape of global dental care, tooth extraction and dental implants are pivotal procedures that significantly influence patient outcomes and practice profitability. As the demand for high-quality dental solutions rises, international B2B buyers must navigate a complex market filled with diverse offerings, regulatory requirements, and technological advancements. This guide serves as a comprehensive resource, meticulously designed to equip buyers from Africa, South America, the Middle East, and Europe—particularly the UK and Brazil—with the insights needed to make informed sourcing decisions.

Understanding the types of tooth extractions and the variety of dental implant options is crucial for selecting the right products. This guide delves into various extraction methods, the latest implant technologies, and the materials that enhance durability and aesthetic appeal. Furthermore, it highlights essential manufacturing and quality control standards that ensure compliance with international regulations.

Buyers will find valuable information on cost structures, supplier evaluations, and market trends, enabling them to make strategic decisions that align with their business goals. The inclusion of FAQs addresses common concerns, fostering confidence in the procurement process. By leveraging this guide, B2B buyers can enhance their operational efficiency and ultimately improve patient satisfaction, positioning themselves for success in the competitive dental market.

Understanding tooth extraction and dental implants Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Simple Extraction | Performed on visible teeth; minimal surgical intervention. | General dentistry practices, dental clinics. | Pros: Quick procedure, lower cost. Cons: Limited to easily accessible teeth. |

| Surgical Extraction | Involves incision; necessary for impacted or hidden teeth. | Oral surgery clinics, specialized dental practices. | Pros: Addresses complex cases. Cons: Higher cost, longer recovery time. |

| Endosteal Implants | Titanium post inserted into the jawbone; most common type. | Implantology, prosthodontics practices. | Pros: Durable, natural appearance. Cons: Requires sufficient bone density. |

| Subperiosteal Implants | Placed under the gum but above the jawbone; alternative for low bone density. | Specialized implant clinics, prosthodontics. | Pros: Suitable for patients with insufficient bone. Cons: Less common, potential for complications. |

| Zygomatic Implants | Anchored in the cheekbone; used when upper jaw is insufficient. | Advanced dental practices, maxillofacial surgery. | Pros: Effective for severe bone loss. Cons: Complex procedure, higher cost. |

Simple Extraction

Simple extractions are the most straightforward type of dental procedure, typically performed when a tooth is visible and accessible. This method involves using dental tools to loosen and remove the tooth without the need for surgical incisions. B2B buyers should consider this option for general dental practices where patients require quick solutions for easily removable teeth. The procedure is cost-effective and requires minimal recovery time, making it an attractive option for clinics looking to provide efficient care.

Surgical Extraction

Surgical extractions are more complex and are used for teeth that are not easily accessible, such as impacted wisdom teeth. This procedure requires incisions in the gum and may involve the removal of bone. B2B buyers in oral surgery clinics should prioritize this option for cases requiring specialized care. While it provides solutions for complicated dental issues, the procedure incurs higher costs and demands longer recovery periods, which must be factored into patient care plans.

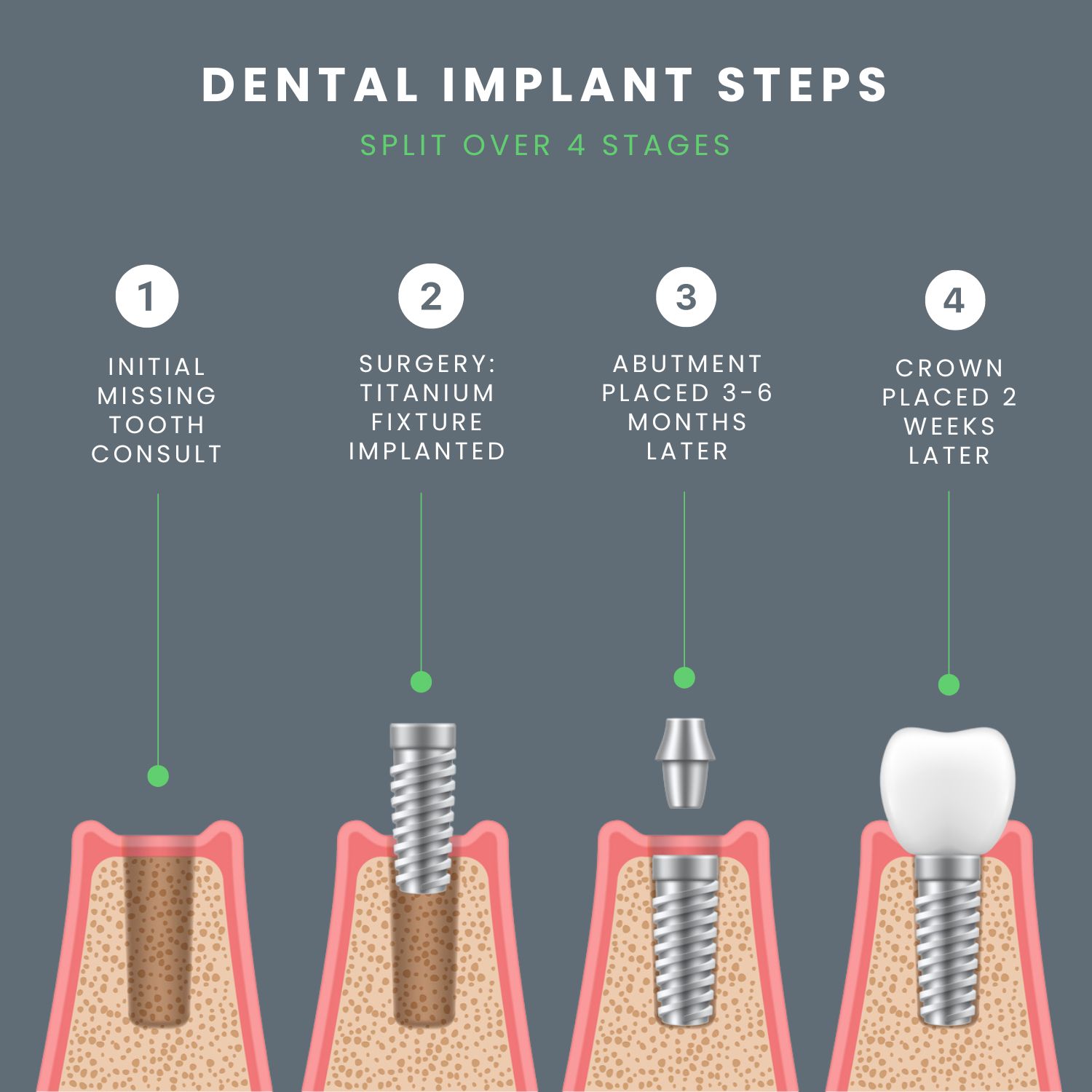

Illustrative Image (Source: Google Search)

Endosteal Implants

Endosteal implants are the most common type of dental implant, featuring a titanium post inserted directly into the jawbone. They are highly durable and can effectively support crowns, bridges, or dentures. B2B buyers in implantology and prosthodontics should consider this option for its natural appearance and functionality. However, it is essential to assess the patient’s bone density, as insufficient bone may complicate the procedure.

Subperiosteal Implants

Subperiosteal implants are placed under the gum tissue but above the jawbone, making them suitable for patients who lack sufficient bone height. This type of implant is less common but offers a viable solution for challenging cases. B2B buyers should consider subperiosteal implants for specialized practices where patients may not be candidates for traditional implants. While they provide a beneficial alternative, potential complications and a less predictable outcome should be acknowledged.

Zygomatic Implants

Zygomatic implants are anchored in the cheekbone, providing an option for patients with significant bone loss in the upper jaw. This advanced procedure is suitable for specialized dental practices and maxillofacial surgery centers. B2B buyers should weigh the benefits of this technique against its complexity and higher costs. While zygomatic implants can be life-changing for patients with severe bone loss, they require skilled practitioners and careful planning to minimize risks.

Related Video: 🦷 Full DENTAL IMPLANT PROCEDURE! Before and After – Extraction, Surgery, & Crown On Back Tooth Molar

Key Industrial Applications of tooth extraction and dental implants

| Industry/Sector | Specific Application of tooth extraction and dental implants | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Use of dental implants for restorative dentistry | Enhances patient satisfaction and retention | Compliance with local regulations, quality certifications |

| Dental Equipment Supply | Manufacturing and distribution of extraction tools and implants | Increases product portfolio and market competitiveness | Sourcing from ISO-certified manufacturers |

| Insurance | Coverage plans for dental extractions and implants | Expands service offerings and attracts new clients | Understanding local healthcare regulations and standards |

| Medical Tourism | Promoting dental procedures abroad, including extractions and implants | Drives revenue through international patient influx | Partnerships with local clinics and compliance with health regulations |

| Education & Training | Training programs for dental professionals on extraction techniques and implantology | Upgrades skills and enhances service quality | Collaboration with accredited dental schools and institutions |

Healthcare

In the healthcare sector, dental implants are crucial for restorative dentistry, providing patients with long-term solutions for missing teeth. The ability to offer high-quality dental implants can significantly enhance patient satisfaction and retention. International buyers must ensure compliance with local healthcare regulations and quality certifications, which can vary widely across regions, particularly in Africa and South America.

Dental Equipment Supply

Companies involved in the manufacturing and distribution of dental equipment play a vital role in providing tools for tooth extractions and implants. By expanding their product portfolio to include advanced extraction tools and high-quality implants, these businesses can increase their market competitiveness. Key sourcing considerations include partnering with ISO-certified manufacturers to ensure product reliability and adherence to international standards.

Insurance

Dental insurance providers can leverage the growing demand for tooth extraction and implant procedures by offering comprehensive coverage plans. This not only expands their service offerings but also attracts new clients seeking financial assistance for dental care. Understanding local healthcare regulations and standards is essential for insurance companies, especially when navigating different markets in Europe, the Middle East, and Africa.

Medical Tourism

The rise of medical tourism has made dental procedures, including extractions and implants, a lucrative sector. Countries known for affordable and high-quality dental care attract international patients seeking these services. To capitalize on this trend, businesses must establish partnerships with reputable local clinics and ensure compliance with health regulations to build trust with prospective patients.

Education & Training

Educational institutions and training programs focused on dentistry can enhance the skills of dental professionals in tooth extraction techniques and implantology. By offering accredited training, these programs not only improve service quality but also contribute to the overall advancement of the dental industry. Collaboration with accredited dental schools and institutions is key to ensuring that training meets international standards and addresses the specific needs of the regions served.

Related Video: How Dentists Insert Dental Implants

Strategic Material Selection Guide for tooth extraction and dental implants

When selecting materials for tooth extraction tools and dental implants, it is crucial to consider their properties, advantages, disadvantages, and compliance with international standards. The following analysis focuses on four common materials: Titanium, Stainless Steel, Zirconia, and Polyether Ether Ketone (PEEK). Each material offers unique characteristics that can significantly impact product performance and application in the dental industry.

Titanium

Key Properties: Titanium is known for its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. It can withstand high temperatures and pressures, making it suitable for various dental applications.

Pros & Cons: Titanium is highly durable and integrates well with bone, which is essential for dental implants. However, it is relatively expensive compared to other materials and requires precise manufacturing techniques, potentially increasing production complexity.

Impact on Application: Titanium is particularly compatible with human tissue, making it the preferred choice for dental implants. Its corrosion resistance ensures longevity in the oral environment, which is often moist and contains various chemicals.

Considerations for International Buyers: Buyers in regions like Africa, South America, the Middle East, and Europe should ensure compliance with standards such as ASTM F136 for titanium alloys. The cost may vary significantly based on local supply chains and import regulations.

Stainless Steel

Key Properties: Stainless steel is known for its high tensile strength, resistance to corrosion, and ease of fabrication. It is suitable for tools used in tooth extractions due to its robustness.

Pros & Cons: While stainless steel is cost-effective and durable, it may not be as biocompatible as titanium, which can limit its use in implants. Additionally, it can corrode over time if not properly maintained.

Impact on Application: Stainless steel is widely used for extraction tools due to its strength and affordability. However, its use in implants is limited, as it may not integrate as well with bone compared to titanium.

Considerations for International Buyers: Compliance with standards like ASTM A276 is essential. Buyers should also consider the local market’s preference for stainless steel tools due to their lower cost, especially in emerging markets.

Zirconia

Key Properties: Zirconia is a ceramic material known for its high strength, aesthetic appeal, and excellent biocompatibility. It has low thermal conductivity and is resistant to wear and corrosion.

Pros & Cons: Zirconia offers a natural tooth-like appearance, making it ideal for visible dental implants. However, it is more brittle than metals, which can lead to fractures under high stress.

Impact on Application: Zirconia is particularly suitable for anterior dental implants where aesthetics are crucial. Its biocompatibility ensures minimal adverse reactions in the body.

Considerations for International Buyers: Buyers should be aware of the need for compliance with ISO 13356 for zirconia materials. The cost of zirconia implants can be higher, which may influence purchasing decisions in price-sensitive markets.

Polyether Ether Ketone (PEEK)

Key Properties: PEEK is a high-performance polymer known for its excellent mechanical properties, chemical resistance, and biocompatibility. It can withstand high temperatures and has a low density.

Pros & Cons: PEEK is lightweight and offers good wear resistance, making it suitable for dental applications. However, it is less rigid than metals, which may limit its use in load-bearing applications.

Impact on Application: PEEK is increasingly used in dental implants and prosthetics due to its flexibility and comfort. It is particularly beneficial in patients with metal allergies.

Considerations for International Buyers: Compliance with ISO 10993 for biocompatibility is essential. PEEK’s cost is generally moderate, making it an attractive option for buyers looking for alternatives to traditional materials.

Summary Table

| Material | Typical Use Case for tooth extraction and dental implants | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Dental implants | Excellent biocompatibility and strength | High cost and manufacturing complexity | High |

| Stainless Steel | Tooth extraction tools | Cost-effective and durable | Less biocompatible for implants | Low |

| Zirconia | Aesthetic dental implants | Natural tooth-like appearance | Brittle under high stress | High |

| PEEK | Dental implants and prosthetics | Lightweight and biocompatible | Less rigid than metals | Medium |

This strategic material selection guide provides critical insights for international B2B buyers, enabling informed decisions that align with both performance requirements and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for tooth extraction and dental implants

Tooth extraction and dental implants are critical components of modern dentistry, necessitating robust manufacturing processes and stringent quality assurance protocols. As B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, understanding these processes can enhance your procurement strategies and ensure the highest quality products for your clients.

Manufacturing Processes for Dental Implants

The manufacturing of dental implants involves several key stages, each critical to ensuring the final product’s performance and reliability.

1. Material Preparation

The choice of materials for dental implants is paramount. Titanium and its alloys are the most commonly used materials due to their biocompatibility, strength, and resistance to corrosion.

- Material Sourcing: Verify that materials are sourced from certified suppliers. Look for certifications such as ISO 13485, which pertains to medical device quality management systems.

- Pre-treatment: Materials undergo processes such as cleaning, sterilization, and surface treatment to enhance osseointegration, which is the process by which the implant anchors to the jawbone.

2. Forming

The forming process shapes the raw materials into the desired implant structures.

- Techniques: Common techniques include:

- CNC Machining: Precision machining is critical for creating the intricate designs of implant posts and abutments.

- Additive Manufacturing: Also known as 3D printing, this method allows for the creation of complex geometries that promote osseointegration.

3. Assembly

Once individual components are formed, they are assembled into complete systems.

- Component Integration: This includes attaching the abutment to the implant post. Ensuring a secure fit is essential for the implant’s longevity and function.

- Quality Checks: Each assembly undergoes initial quality checks to ensure all components meet design specifications.

4. Finishing

The finishing stage is crucial for enhancing the implant’s surface characteristics.

- Surface Treatments: Techniques such as sandblasting, acid etching, or anodization improve the surface texture, promoting better integration with bone tissue.

- Final Inspection: A thorough inspection is conducted to ensure that the implants are free from defects and meet all regulatory standards.

Quality Assurance Protocols

Quality assurance (QA) is essential to ensure the safety and efficacy of dental implants. Various international standards and industry-specific regulations guide these processes.

Relevant International Standards

- ISO 9001: This standard outlines the requirements for a quality management system and is applicable across industries.

- ISO 13485: Specifically for medical devices, this standard focuses on the quality management systems that ensure consistent design, development, and manufacturing of products.

- CE Marking: In Europe, products must meet health, safety, and environmental protection standards to receive CE marking, indicating compliance with EU regulations.

Quality Control Checkpoints

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints designed to catch defects early.

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from standards.

- Final Quality Control (FQC): After assembly and finishing, the final product undergoes rigorous testing to ensure it meets all quality and regulatory standards.

Common Testing Methods

- Mechanical Testing: Implants are subjected to tensile, compressive, and fatigue tests to ensure they can withstand the forces they will encounter in the mouth.

- Biocompatibility Testing: Ensures that materials used do not elicit an adverse reaction in the body.

- Sterility Testing: Vital for ensuring that the implants are free from microbial contamination before they reach the market.

Verifying Supplier Quality Control

As an international B2B buyer, verifying the quality control measures of your suppliers is crucial. Here are some actionable steps:

- Audits: Conduct regular audits of suppliers to assess compliance with quality standards and regulations. This can be done either in-person or remotely.

- Quality Reports: Request comprehensive quality assurance reports that detail the QC processes followed, including test results and compliance certifications.

- Third-Party Inspections: Engage third-party inspection services to conduct independent assessments of suppliers’ manufacturing and quality assurance processes.

Navigating Regulatory Nuances for International Buyers

When sourcing dental implants, understanding the regulatory landscape is vital, especially for buyers from diverse regions.

- Africa: Familiarize yourself with local regulations governing medical devices, which may vary significantly by country. Some regions may have less stringent requirements, increasing the importance of supplier reliability.

- South America: The regulatory framework can be complex; ensure that suppliers are compliant with ANVISA (Brazil) or similar agencies in other countries.

- Middle East: Countries like Saudi Arabia require SFDA approval for medical devices. It’s crucial to confirm that suppliers can provide the necessary documentation.

- Europe: In addition to CE marking, buyers should be aware of the Medical Device Regulation (MDR), which imposes strict requirements on manufacturers.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for tooth extraction and dental implants is essential for B2B buyers looking to procure high-quality dental products. By focusing on material preparation, forming, assembly, and finishing, while ensuring adherence to international standards and rigorous quality control measures, buyers can secure reliable suppliers that meet the demands of their markets. Engaging in thorough supplier verification processes will further enhance product quality and compliance, ultimately leading to better outcomes for dental professionals and their patients.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for tooth extraction and dental implants Sourcing

Tooth extraction and dental implants are essential components of modern dentistry, with significant implications for both patient care and business operations. Understanding the cost structure and pricing dynamics is crucial for B2B buyers in the dental supply chain, particularly those operating across diverse regions such as Africa, South America, the Middle East, and Europe.

Cost Structure

A comprehensive cost analysis for tooth extraction and dental implants involves several key components:

-

Materials: The choice of materials significantly influences costs. For dental implants, titanium is commonly used due to its biocompatibility and strength. The price of high-quality titanium can range from $100 to $300 per implant. Additionally, the components of the implant system, such as abutments and crowns, add to material costs.

-

Labor: Labor costs vary by region and the complexity of the procedure. Skilled labor is essential for both extraction and implant placement, with costs often accounting for 20-30% of the overall price.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. Efficient manufacturing processes can help reduce overhead, impacting the final pricing structure.

-

Tooling: Specialized tools for extraction and implant procedures require investment. The costs of maintaining and upgrading these tools must be factored into the overall pricing.

-

Quality Control (QC): Ensuring compliance with international standards (e.g., ISO 13485) incurs costs but is crucial for maintaining product integrity and safety. Quality certifications can enhance marketability but may increase upfront costs.

-

Logistics: Transportation and distribution costs are critical, especially for international buyers. Factors such as shipping distances, customs duties, and warehousing can significantly affect the total cost.

-

Margin: Suppliers typically apply a profit margin that can vary based on market conditions, competition, and perceived value of the products. Margins can range from 20% to 50%, depending on the supplier’s positioning and market strategy.

Price Influencers

Several factors influence the pricing of tooth extraction and dental implants:

-

Volume/MOQ: Bulk purchasing often leads to cost reductions. Buyers should negotiate minimum order quantities (MOQ) to benefit from lower per-unit prices.

-

Specifications and Customization: Custom implants or specific configurations may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Quality and Certifications: Higher-quality materials and certified products typically command higher prices. Buyers should assess the balance between quality and cost-effectiveness.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium, but they often offer better support and product guarantees.

-

Incoterms: Understanding the terms of trade (Incoterms) is crucial for international transactions. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can influence overall costs.

Buyer Tips

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-efficiency:

-

Negotiation: Engage suppliers in discussions to negotiate better terms, especially for large orders. Building long-term relationships can also lead to favorable pricing.

-

Total Cost of Ownership (TCO): Consider not only the purchase price but also the long-term costs associated with maintenance, warranties, and potential replacements. A lower initial price may lead to higher TCO if quality is compromised.

-

Pricing Nuances: Be aware of regional price variations. For instance, dental implants may be more affordable in certain markets due to lower labor costs. Understanding these nuances can help in making informed sourcing decisions.

-

Stay Informed: Keep abreast of market trends, technological advancements, and regulatory changes that may affect pricing and availability. This knowledge can provide leverage in negotiations and sourcing strategies.

Disclaimer

Prices mentioned are indicative and may vary based on specific circumstances, including location, supplier, and market conditions. Always conduct thorough due diligence and obtain quotes from multiple suppliers to ensure competitive pricing.

Essential Technical Properties and Trade Terminology for tooth extraction and dental implants

Tooth extraction and dental implants are critical components of modern dentistry, and understanding their technical properties and trade terminology is essential for B2B buyers looking to navigate this industry effectively. Below is a breakdown of the key specifications and terms that are pivotal in this market.

Essential Technical Properties

-

Material Grade

– Dental implants are predominantly made from titanium or zirconia. Titanium is preferred for its biocompatibility, strength, and ability to integrate with bone. Zirconia, while aesthetically superior, is often used in specific cases where metal-free options are desired. Understanding the material grade is crucial for ensuring product quality and longevity. -

Tolerance

– Tolerance refers to the allowable deviation in the dimensions of implant components. High precision is necessary, especially for the implant post and abutment, to ensure proper fit and function. Tighter tolerances can lead to better osseointegration and reduced risk of complications, making this a vital specification for manufacturers and suppliers. -

Surface Treatment

– The surface of dental implants undergoes various treatments to enhance osseointegration, such as sandblasting or acid etching. These treatments increase the surface area and promote bone attachment. B2B buyers must consider these properties as they directly affect the success rates of implants. -

Load-Bearing Capacity

– This specification indicates the maximum load an implant can withstand without failure. It is critical for ensuring that the implant can support the forces exerted during chewing. Understanding load-bearing capacity helps in selecting the right implant for specific patient needs. -

Sterilization Standards

– Compliance with sterilization standards (e.g., ISO 13485) is essential for ensuring the safety of dental products. B2B buyers should verify that suppliers adhere to these standards to mitigate the risk of infection and complications during procedures. -

Implant Design

– The design of dental implants (e.g., cylindrical, tapered) influences their stability and aesthetic outcomes. Different designs suit various clinical situations, and understanding these can help buyers make informed decisions about which products to source for their markets.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that manufacture products that are then sold under another company’s brand. Understanding OEM relationships is crucial for buyers looking to source quality dental implants and components. -

MOQ (Minimum Order Quantity)

– MOQ defines the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and initial investment costs. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. It is essential for buyers to articulate their needs clearly in an RFQ to receive accurate and competitive quotes. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and obligations associated with importing dental products. -

CE Marking

– This mark indicates that a product meets EU safety and health standards. For B2B buyers in Europe, ensuring that dental implants are CE marked is critical for compliance and marketability. -

Regulatory Compliance

– This term encompasses all the legal requirements a product must meet to be sold in a particular market. Understanding regulatory compliance is essential for avoiding legal issues and ensuring patient safety.

By familiarizing themselves with these technical properties and terms, B2B buyers can make informed decisions when sourcing tooth extraction and dental implant products, ensuring quality and regulatory compliance while optimizing their supply chain processes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the tooth extraction and dental implants Sector

Market Overview & Key Trends

The tooth extraction and dental implants sector is experiencing significant growth, driven by factors such as increasing dental health awareness, an aging population, and advancements in technology. The global dental implant market is projected to reach approximately $12 billion by 2027, with a compound annual growth rate (CAGR) of around 6.4%. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic sourcing.

Emerging trends in sourcing include the adoption of digital dentistry tools, such as CAD/CAM systems, which enhance precision in implant manufacturing and improve patient outcomes. Additionally, the rise of tele-dentistry is reshaping how dental care is delivered, providing patients with easier access to consultations and follow-ups. B2B buyers should consider suppliers that integrate these technologies to enhance their service offerings.

Furthermore, the market is witnessing a shift towards personalized dental solutions, with custom implants becoming more prevalent. This trend is accompanied by an increase in collaborative partnerships between manufacturers and dental professionals to develop innovative products tailored to specific patient needs. Buyers should evaluate suppliers based on their capacity for customization and responsiveness to market changes.

Sustainability & Ethical Sourcing in B2B

As environmental concerns grow, sustainability has become a critical focus within the dental industry. The production of dental implants and tools involves significant resource consumption and waste generation, prompting a shift towards greener practices. For B2B buyers, partnering with manufacturers that prioritize sustainability can enhance their brand reputation and meet the increasing consumer demand for environmentally friendly products.

Ethical sourcing is vital in ensuring that materials used in dental procedures, such as titanium for implants, are obtained responsibly. Buyers should seek suppliers who provide transparency regarding their supply chains and hold certifications such as ISO 14001 for environmental management. Additionally, using biodegradable or recyclable materials in dental tools can further reduce environmental impact.

Engagement with suppliers that have implemented sustainable practices not only aligns with global trends but also positions businesses as leaders in ethical responsibility. This approach can lead to improved customer loyalty and trust, essential in a competitive market.

Brief Evolution/History

The dental sector has evolved significantly over the last century, transitioning from rudimentary extraction methods to advanced implant technologies. In the mid-20th century, the introduction of titanium as a biocompatible material revolutionized dental implants, allowing for more durable and effective solutions. The evolution continued with the advent of computer-aided design (CAD) and manufacturing (CAM), enhancing the precision and customization of dental implants.

Today, the industry is moving towards a more integrated approach, where technology and sustainability go hand in hand. This evolution presents numerous opportunities for B2B buyers to capitalize on innovative solutions while addressing the growing demand for ethical and sustainable practices. Understanding this history is essential for making informed decisions in an ever-evolving market landscape.

Related Video: Full Mouth Dental Implants: Everything You Need to Know and Cost

Frequently Asked Questions (FAQs) for B2B Buyers of tooth extraction and dental implants

-

What should I consider when vetting suppliers for tooth extraction and dental implant products?

When vetting suppliers, prioritize their compliance with international quality standards such as ISO 13485 and CE marking. Check for certifications that validate their manufacturing processes and product safety. Additionally, assess their experience in exporting to your region, as this can influence logistics and support. Request samples to evaluate product quality and engage with references from other international buyers to gain insights into their reliability and service. -

Can dental implants and extraction tools be customized to meet specific market needs?

Yes, many manufacturers offer customization options for dental implants and extraction tools. This can include variations in size, material, and design based on regional preferences or specific clinical requirements. When discussing customization, ensure to communicate your needs clearly and inquire about the feasibility, potential costs, and lead times associated with producing customized products. -

What are typical minimum order quantities (MOQs) and lead times for dental implants?

MOQs can vary significantly among suppliers, often ranging from 50 to 100 units for dental implants and extraction tools. Lead times typically depend on the supplier’s inventory and production capabilities; expect anywhere from 4 to 12 weeks for standard orders. For urgent needs, discuss expedited options and any associated costs. Understanding these factors is crucial for planning your inventory and meeting market demands. -

How can I ensure the quality assurance (QA) of dental products sourced internationally?

To ensure QA, request detailed documentation from suppliers, including quality control processes, inspection reports, and compliance certificates. Engage in third-party audits if possible, and consider utilizing a trusted local agent to oversee the quality of shipments. It is also beneficial to understand the supplier’s return policy and warranty terms to safeguard against defective products. -

What payment terms are commonly accepted in international B2B transactions for dental products?

Payment terms can vary, but options like letters of credit, wire transfers, and payment upon delivery are frequently used in international trade. Negotiate terms that minimize risk while ensuring supplier confidence. Be cautious of upfront payments, and consider establishing an escrow arrangement for larger orders to protect both parties until the transaction is satisfactorily completed.

Illustrative Image (Source: Google Search)

-

What logistics considerations should I be aware of when importing dental products?

Logistics can significantly impact your supply chain efficiency. Ensure you understand customs regulations and import duties applicable to your region. Collaborate with logistics providers experienced in handling medical devices to streamline the shipping process. Additionally, factor in potential delays at customs and consider using tracking systems for better visibility of your shipment status. -

How can I handle disputes with suppliers in international transactions?

Establish clear contracts that outline terms of service, payment, delivery timelines, and dispute resolution procedures. Consider including arbitration clauses to resolve disputes amicably. If a dispute arises, maintain open communication with the supplier to negotiate a solution. If necessary, leverage the support of trade associations or legal advisors familiar with international trade laws in your region. -

What certifications should I look for when sourcing dental implants and extraction tools?

Key certifications to look for include ISO 13485 for quality management systems and CE marking for compliance with European health, safety, and environmental protection standards. Depending on your market, you may also need FDA approval (for the USA), ANVISA registration (for Brazil), or other local certifications. Verify these credentials with the supplier to ensure the products meet regulatory requirements in your target market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for tooth extraction and dental implants

In conclusion, strategic sourcing in the tooth extraction and dental implant sector is essential for international B2B buyers aiming to enhance their product offerings and operational efficiencies. Key takeaways include the importance of understanding diverse market needs, navigating regulatory landscapes, and leveraging technological advancements in dental manufacturing. Establishing strong relationships with reliable suppliers can lead to improved quality, cost management, and timely access to innovations that meet evolving patient demands.

Value of Strategic Sourcing:

– Cost Efficiency: By carefully selecting suppliers, buyers can negotiate better pricing and terms, directly impacting profitability.

– Quality Assurance: Partnering with manufacturers who adhere to international standards ensures high-quality products that enhance patient outcomes.

– Market Adaptability: A robust sourcing strategy allows businesses to swiftly respond to market changes, such as trends in dental aesthetics and technology.

As the global dental market continues to evolve, now is the time for buyers from Africa, South America, the Middle East, and Europe to invest in strategic sourcing initiatives. By doing so, they can position themselves at the forefront of the industry, ready to meet the growing demand for tooth extraction and dental implant solutions. Embrace these opportunities and drive your business forward in this vital sector.